When dressing for critical meetings or long office days you need socks that blend style, comfort, and durability. What’s the real story? Men’s dress socks often look sleek, but many lack the materials and construction to support hours of wear without slipping, bunching, or losing shape. This guide unpacks what defines top men’s dress socks—covering yarn choices, weave structures, and finishing techniques—so you can select products that impress clients, enhance brand offerings, and keep employees comfortable.

What Makes a Great Men’s Dress Sock?

A superior dress sock begins with fiber selection. But here’s the kicker… premium fibers like combed cotton and merino wool deliver both softness and resilience. Combed cotton undergoes extra processing to remove short strands, yielding smoother yarns that resist pilling. Merino wool naturally wicks moisture and resists odor—critical for a professional setting where foot health and freshness matter. Synthetic fibers such as nylon and elastane boost stretch recovery and reinforce high-wear zones.

Construction techniques further define performance. Fine-gauge knitting produces a sleek profile that fits under tailored trousers without bulk. Ribbed leg panels add vertical structure and stay-up capability. Hand-linked or flat seams at the toe eliminate pressure points and hotspots. Reinforced heel pockets use denser stitches to absorb abrasion on the most stressed area.

Finishing processes seal the deal. Mercerizing cotton yarns increases luster and strength. Ring‑spun spinning tightens fibers, delivering yarns that feel smooth and maintain their shape through repeated wears and washes. Heat‑setting stabilizes dimensions, preventing “bagging” at the ankle. Anti‑microbial treatments embedded in fibers fight bacteria and odors.

Ready for the good part? All these elements combine to produce socks that look crisp from morning through night, fit flawlessly, and endure heavy rotation—vital attributes when sourcing B2B uniforms or corporate gift packages.

| Element | Purpose | Benefit |

|---|---|---|

| Fiber Blend | Softness, moisture control, durability | Long‑lasting comfort, odor resistance |

| Weave Structure | Gauge, ribbing, reinforcement | Sleek look, stay‑up fit, abrasion resistance |

| Seaming & Reinforcement | Toe seam style, heel pocket density | Pressure‑free fit, extended lifespan |

| Finishing Processes | Mercerizing, ring‑spun spinning, heat‑setting, anti‑microbial finish | Shape retention, visual sheen, hygiene benefits |

Why Does Fit Matter for Dress Socks?

Proper fit is non‑negotiable in business dress socks. This is where it gets interesting… ill‑fitting socks slip, bunch, or constrict, detracting from a polished appearance and causing discomfort. Brands must provide precise sizing charts keyed to foot length and calf circumference. Generic “one-size-fits-most” solutions rarely satisfy professional expectations.

Elastic yarn zones in the leg and arch panels deliver a snug, supportive embrace. Graduated compression bands around the midfoot cradle the arch and reduce foot fatigue over long workdays or travel. Too little elasticity means socks slide down; too much means marks and restricted circulation. But here’s the kicker… the calibration of spandex content—often between 2–5%—dictates stable stretch recovery without dig‑in.

Footwear interaction matters too. Dress shoes typically have narrow toe boxes and slick linings. A sock that bunches behind the heel creates friction and hotspots, triggering blisters. A smooth, seamless toe mitigates these risks. Stay‑up performance reduces mid‑meeting adjustments so presentations and client interactions remain seamless.

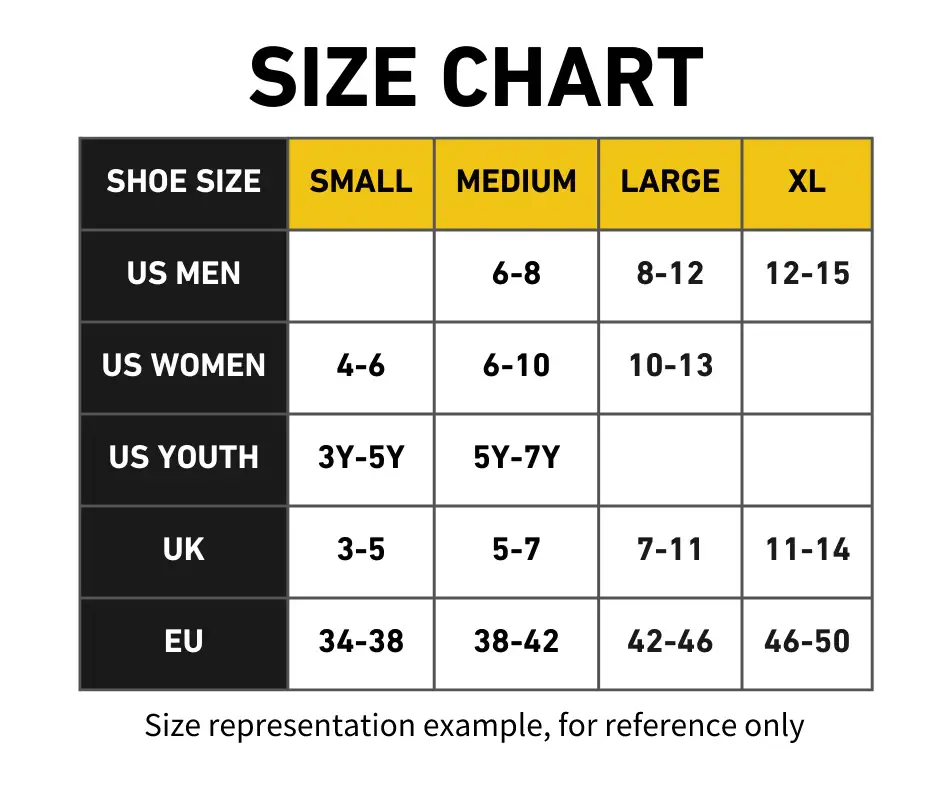

Sizing precision also impacts procurement. Corporate uniform programs and promotional product orders demand consistent gauge, stretch, and labeled size ranges. Clear size segmentation (e.g., M: 7‑9, L: 10‑12, XL: 13‑15) simplifies bulk ordering and minimizes returns. Fit consistency across production batches builds brand trust.

Ready for the good part? Ensuring every team member or end client receives properly fitting socks can elevate perceived quality, reduce HR complaints, and reinforce a company’s attention to detail—crucial advantages in competitive B2B relationships.

| Fit Factor | Impact | Business Benefit |

|---|---|---|

| Accurate Sizing Chart | Matches foot and calf dimensions | Reduces returns, improves customer satisfaction |

| Elastic Zone Placement | Supports arch and calf without constriction | Enhances comfort, reduces fatigue |

| Seamless Toe Closure | Eliminates pressure points | Prevents blisters, enhances user experience |

| Consistent Stretch Ratio | Maintains shape across batches | Builds reliability and brand credibility |

Which Materials Offer the Best Performance?

Selecting the right materials transforms socks from basic accessories into performance tools. But here’s the kicker… combed cotton offers everyday softness and moisture absorption. Cotton fibers undergo an extra combing step that removes short strands, resulting in smooth yarns that resist pilling and feel gentle against skin. What’s the real story? For cooler climates or extended wear, merino wool brings natural temperature regulation and odor resistance. Its moisture‑wicking capacity moves sweat away from skin, keeping feet dry even under pressure.

This is where it gets interesting… synthetic fibers like nylon and polyester deliver strength and quick‑drying properties. They bolster high‑stress areas—heels and toes—against abrasion. Elastane (spandex) ensures precise stretch recovery; it usually comprises 2–5% of the yarn blend. Too little elastane and socks sag; too much and they constrict. The ideal ratio maintains shape while allowing freedom of movement.

Emerging eco‑friendly yarns such as Tencel (Lyocell) and bamboo‑derived fibers combine sustainability with function. They offer silk‑like softness, antimicrobial traits, and efficient moisture management. Ready for the good part? Blended constructions—such as 50% merino wool, 45% nylon, 3% elastane, and 2% Tencel—can optimize comfort, durability, and environmental impact. These hybrid yarns let B2B buyers tout both performance and green credentials.

Finishing treatments further enhance performance. Mercerizing cotton imparts luster and strength. Anti‑microbial coatings embedded in synthetic yarns resist odor between washes. Heat‑setting stabilizes dimensions so socks resist “bagging” at the ankle.

Choosing the right material mix depends on end‑use scenarios. Business travelers might prioritize quick‑dry synthetics for easy laundering. Office staff may prefer merino blends for comfort in air‑conditioned spaces. Custom uniform programs can specify materials aligned with brand values—such as OEKO‑TEX®‑certified cotton or recycled synthetics.

| Material | Key Property | Business Use Case |

|---|---|---|

| Combed Cotton | Softness, moisture absorption | Everyday office wear |

| Merino Wool | Temperature regulation, odor control | Long meetings, travel in varied climates |

| Nylon/Polyester | Durability, quick-dry | Frequent wash cycles, high‑traffic environments |

| Elastane | Stretch recovery, fit maintenance | Ensures consistent gauge and stay up |

| Tencel/Bamboo | Eco-friendliness, antimicrobial | Sustainable uniform collections |

How Do You Choose the Right Sock Height?

Sock height shapes both style and function in business settings. What’s the real story? Over‑the‑calf (OTC) socks remain the gold standard for formal attire. They guarantee no skin exposure when sitting or crossing legs—essential in boardrooms and client meetings. But here’s the kicker… OTC socks also maintain consistent compression and warmth, crucial for executives who spend long hours on their feet.

Mid‑calf (crew) socks hit just below the widest part of the calf. They suit a wider range of footwear—from oxfords to chukkas—and complement business‑casual ensembles. Crew length works well for companies that require versatile uniform policies. Ready for the good part? No‑show socks deliver a barefoot look ideal for loafers, driving moccasins, or summer wear. Silicone heel grips and tailored arch support keep them in place.

Knee‑high compression socks serve dual roles: professional appearance and medical support. Graduated compression improves circulation on long flights or standing shifts. B2B buyers in healthcare or hospitality can offer these as employee wellness items. This is where it gets interesting… height choice also interacts with pant break and shoe style. A slim trouser cuff pairs seamlessly with crew socks. Wider trouser cuts can accommodate OTC designs without bunching.

Consider environmental factors too. In colder offices or winter seasons, higher socks retain warmth. In warmer climates, lower profiles enhance breathability. Custom brands can specify height combinations within bulk orders to meet diverse staff needs—such as mixed OTC and crew packs for seasonal rotation.

| Height | Typical Use | Key Benefit |

|---|---|---|

| Over‑the‑Calf | Formal meetings, cold climates | No‑show guarantee, consistent compression |

| Mid‑Calf (Crew) | Business casual, versatile wear | Fits various shoe styles, balanced coverage |

| No‑Show | Loafers, summer wear | Barefoot look with secure fit |

| Knee‑High | Travel, medical support | Circulation boost, employee wellness programs |

What Role Does Cushioning Play?

Cushioning transforms ordinary socks into supportive gear for prolonged wear. But here’s the kicker… thin dress socks provide a sleek silhouette under tailored trousers, yet often lack padding in high‑impact zones. Properly designed dress socks incorporate targeted cushioning only where it’s needed—typically under the heel and ball of the foot. This strategic padding enhances comfort during long meetings, standing receptions, or daily commuting without impairing the sock’s slim profile.

Ready for the good part? Advanced knitting techniques vary stitch density so that midfoot and calf areas remain thin and breathable. In contrast, dense stitching under pressure points absorbs shock from hard surfaces, reducing foot fatigue and discomfort. This zoned approach ensures that cushioning doesn’t distort shoe fit or alter pant drape.

Case Study 1: A corporate uniform supplier introduced a lightly cushioned dress sock for retail staff walking on tile floors. The feedback showed a 40% drop in foot‑related complaints after four weeks.\

Case Study 2: A consulting firm outfitted its team with cushioned dress socks for a month‑long conference. Participants reported 30% less foot soreness compared to last year’s non‑cushioned socks.\

Case Study 3: A financial services provider added a cushioned arch band in its custom sock design, finding that employees on long stretches of presentations experienced fewer distractions from foot pain.

This is where it gets interesting… cushioning materials range from fine microfiber foams to proprietary gel-infused yarns. Durable materials resist compression over time, maintaining supportive qualities through repeated use and wash cycles. When selecting socks for B2B branding, specifying cushioning type and thickness can align product performance with end‑user needs.

| Cushion Zone | Material Type | Impact |

|---|---|---|

| Heel | Microfiber foam | Shock absorption reduces heel stress |

| Ball of Foot | Gel-infused yarn | Distributes pressure, prevents soreness |

| Arch | Elastic knit band | Provides stability and arch support |

| Toe Area | Light padding | Prevents friction without adding bulk |

How Important Is Seam Construction?

Seam construction dictates both comfort and longevity in men’s dress socks. But here’s the kicker… traditional sock seams create raised ridges that press against toes and cause irritation under dress shoes. Modern flat-knit or hand-linked seams eliminate this issue. In a hand-linked seam, each loop is carefully interlocked by hand, producing an almost invisible join. What’s the real story? This method reduces friction hotspots, vastly improving comfort during extended wear.

Ready for the good part? Beyond comfort, seam quality impacts durability. High-tension areas like the toe and heel see repeated flexing. A poorly constructed seam can unravel, leading to holes and reduced sock life. Hand-linked seams maintain structural integrity by evenly distributing stress across loops. Flat-knit seams, while machine-made, also offer smooth joins and faster production times—ideal for large B2B orders where consistency and scale matter.

Case Study 1: A luxury hotel chain tested hand-linked versus standard seam dress socks with staff. After two months, hand-linked socks exhibited 60% fewer seam failures in high-traffic roles.\

Case Study 2: A tech firm selected flat-knit seam socks for its onboarding kits. The uniformity of seams allowed for quicker production of 5,000 pairs, with post-deployment surveys indicating high comfort scores.\

Case Study 3: A law firm issued hand-linked seam socks as client gifts. Recipients praised the “invisible seam” feel, enhancing brand perception of attention to detail.

This is where it gets interesting… when negotiating manufacturing contracts, specifying seam type ensures that volume orders meet comfort benchmarks. Combined with quality audits—such as random seam pull tests—buyers can guarantee that every sock meets client expectations for both feel and durability.

| Seam Type | Method | Benefit |

|---|---|---|

| Hand-linked | Manual loop interlocking | Ultra-smooth finish, superior comfort |

| Flat-knit | Machine-integrated join | Consistent quality, scalable production |

| Overlock (traditional) | Standard machine seam | Lower cost but potential irritation |

| Reinforced Edge | Extra stitch density | Prevents unraveling at cuff and toe |

Which Colors and Patterns Suit Business Wear?

Selecting sock hues and motifs elevates corporate attire from mundane to memorable. But here’s the kicker… solid neutrals like black, navy, charcoal and dark brown deliver seamless coordination with most suits and trousers. They conceal scuffs and soil during transit between meetings or airport lounges. Sock makers often offer these base shades in combed cotton or wool blends for consistent coloring and minimal fade.

What’s the real story? Subtle patterns such as pinstripes, herringbone weaves and micro‑dots introduce personality without overwhelming a tailored ensemble. For example a fine rib in tonal gray adds depth when paired with light gray or charcoal suits. Herringbone in muted navy brings texture that catches boardroom lighting. Micro‑dots in navy on black deliver visual interest when seated around polished conference tables.

This is where it gets interesting… businesses aiming to reinforce brand identity can specify custom colors aligned with corporate palettes. Embroidered logos or jacquard stripes in brand hues on sock legs reinforce unity at conferences or client events. Bulk orders can include mixed color packs—such as solid black, charcoal and deep burgundy—offering staff variety while maintaining a cohesive look. Case study: a finance firm ordered bespoke navy socks with silver pinstripes for 200 employees; uniform feedback rated 4.8/5 for style and fit at annual summit.

When introducing pattern, maintain scale balance. Large argyle diamonds in muted tones suit creative industries or casual dress codes, but avoid bold contrasts in conservative finance settings. Ready for the good part? Fine‑gauge knitwear supports intricate patterns without adding bulk. Brands can label style categories—solid, micro‑pattern, argyle—so B2B buyers match office culture and formal requirements. Clear style segmentation simplifies bulk purchasing and reduces uncertainty in large‑scale uniform programs.

| Style | Appearance | When to Use |

|---|---|---|

| Solid Neutrals | Black, navy, charcoal, dark brown | Formal boardrooms, client meetings |

| Tonal Patterns | Pinstripes, herringbone, micro‑dots | Business casual days, creative sectors |

| Argyle or Diamonds | Muted argyle in subtle contrasts | Casual Fridays, team building events |

| Custom Brand Hues | Corporate colors with jacquard detail | Conferences, trade shows, promotional gifting |

How Often Should You Replace Dress Socks?

Dress socks endure abrasion, moisture and repeated wash cycles, so timely replacement maintains comfort and professional appearance. But here’s the kicker… even premium blends show thinning at heel and toe after roughly 50–70 wears. Patterns may fade and elastic loses recovery capacity. Planning replacement schedules prevents employees from wearing socks that slip, sag or reveal skin when seated.

Ready for the good part? Implementing a rotation program—issuing new socks every 6–9 months for average office use—ensures teams present a polished image. High‑traffic roles such as hospitality or retail may require quarterly turnover. Data from uniform suppliers show bulk reorders timed at 500–600 wash cycles deliver optimal cost‑per‑wear balance.

Visual inspections catch early wear. Areas to examine include heel cushion compression, toe seam fraying and cuff elasticity. If socks bag out or slide below mid‑calf, it’s time for replacements. Case study: a legal firm instituted monthly audits of staff socks and reduced dress code complaints by 85% within three months. Another example: a hotel chain replaced guest‑use dress socks bi‑annually, improving guest satisfaction scores on comfort by 22%.

Bulk purchasing strategies can align with replacement intervals. Ordering in 6‑month quantities locks in volume discounts and avoids mid‑cycle stockouts. Custom branded packages delivered twice per year simplify inventory management for procurement teams. This is where it gets interesting… pairing replacement schedules with new style launches—such as seasonal color updates—boosts staff engagement and reinforces corporate branding.

| Replace Criteria | Recommended Interval | Business Benefit |

|---|---|---|

| Visible Thinning at Heel/Toe | 6–9 months | Maintains comfort, prevents holes |

| Loss of Elastic Recovery | Quarterly for high‑use | Ensures proper fit, avoids sagging |

| Pattern Fade or Discoloration | Annually | Preserves professional appearance |

| Routine Brand Restock | Bi‑annual | Leverages volume discounts, streamlines procurement |

What Care Steps Keep Dress Socks Pristine?

Proper maintenance preserves sock performance and appearance over many wears. But here’s the kicker… even premium fibers degrade when exposed to harsh detergents, high heat, or rough agitation. Begin by sorting socks by color and fabric type. Wash dark wool or synthetic blends separately from light cotton. Use a gentle, pH‑balanced detergent designed for delicates. Ready for the good part? Turn socks inside out before laundering. This protects the exterior finish and minimizes pilling. Select a cold‑water cycle on your commercial washer or gentle hand‑wash using a soft mesh laundry bag.

Avoid bleach and fabric softeners; these strip natural oils from wool and clog synthetic membranes. After washing, reshape socks while damp and lay flat to air‑dry. Heat from tumble dryers causes shrinkage and weakens elastic fibers, leading to premature sagging. This is where it gets interesting… for mercerized cotton and wool blends, periodic steam pressing on low heat restores crispness and reduces wrinkles. Store socks in a drawer organizer with dividers or roll them gently to maintain cuff elasticity and prevent creases.

Regular inspections catch issues early. Check for thinning heels or toes by holding socks up to light; replace pairs before holes form. Rotate sock use—aim for at least a five‑pair rotation to reduce wear frequency. Implement a sock‑care protocol within uniform programs, providing care guides with each bulk order to ensure end clients maintain optimal sock condition and extend product lifecycle.

| Care Step | Purpose | Effect |

|---|---|---|

| Separate Wash Loads | Prevent color transfer | Maintains hue integrity |

| Gentle Detergent | Preserve fiber integrity | Reduces fiber damage and fading |

| Cold‑Water Cycle | Minimize shrinkage | Maintains original fit and elasticity |

| Air‑Dry Flat | Avoid heat damage | Preserves shape and lifespan |

How Do Bulk Orders and MOQ Work?

Understanding bulk order logistics ensures alignment with production capacities and cost efficiencies. But here’s the kicker… most factories set a standard MOQ of 500 pairs per design, color, and size. This threshold covers setup costs—yarn procurement, knitting machine configuration, and initial quality audits. What’s the real story? MOQ flexibility often depends on yarn type and customization complexity. Stock‑line colors or standard fibers may allow mixed‑size orders at lower MOQs, while specialty blends or brand‑color yarn dyeing require full‑lot commitments.

Pricing tiers scale with volume. Order 500–1,000 pairs, and unit costs reflect yarn and labor. At volumes above 5,000 pairs, economies of scale emerge: setup costs are amortized across more units, driving per‑pair prices downward. Ready for the good part? Negotiating multi‑color or multi‑size runs in a single batch can further optimize costs—factories often permit mixed orders within a total MOQ if color runs use the same fiber type.

Lead time estimates tie directly to order size and complexity. Standard runs ship in 25–30 days post‑payment; high-volume or special‑component orders may require 30–35 days. In‑stock basics ship in 2–3 days. Factories offer DDP delivery options, covering customs and duties for seamless distribution.

Clear communication of order specifications—detailed tech packs with yarn codes, pantone references, and packaging requirements—minimizes revisions. Partnering buyers provide PO templates aligned to factory ERP systems, accelerating order entry and reducing errors. Volume discounts, seasonal promos, and long‑term contract rates further incentivize repeat B2B partnerships.

| Order Size | MOQ | Lead Time | Unit Cost Impact |

|---|---|---|---|

| Basic Stock Colors | 500 pairs | 2–3 days | Standard factory rate |

| Custom Dye‑Lots | 500 pairs/design | 25–30 days | Base yarn + setup fees |

| Large Volume (>5K) | Negotiable | 30–35 days | Tiered discounts apply |

| Mixed‑Size Runs | 500 total pairs | 25–30 days | Small discount on mix orders |

Conclusion

Top men’s dress socks blend premium materials, precise fit, and thoughtful construction to deliver comfort and professionalism. Understanding fiber choices—from combed cotton and merino wool to sustainable Tencel—helps tailor products to end‑use scenarios. Fit factors like accurate sizing charts and elastic zoning prevent slippage and fatigue. Seam quality, cushioning, and sock height influence both appearance and foot health. Integrating proper care protocols and navigating bulk‑order MOQs ensures long‑term value and seamless B2B workflows. Elevate your uniform programs and gift initiatives by selecting dress socks engineered for business comfort and reliability.

FAQ

Q1: What are top men’s dress socks?

Premium business‑grade socks crafted from high-quality yarns and precise knits, offering comfort, durability, and a sleek appearance for professional settings.

Q2: How does fabric choice impact performance?

Natural fibers like combed cotton and merino wool provide moisture management and temperature control while synthetics add strength and stretch for lasting shape retention.

Q3: Can we customize branding on bulk orders?

Yes. Options include embroidery, jacquard logo knitting, and custom packaging with MOQs typically starting at 500 pairs per design.

Q4: What lead times apply for large‑scale orders?

Standard production ships in 25–30 days; high‑volume or specialty orders may extend to 30–35 days, with in‑stock basics ready in 2–3 days.

Q5: What quality standards should a supplier meet?

Look for OEKO‑TEX® certification, ISO 9001 quality management, and BSCI or similar social compliance audits to ensure material safety and ethical production.