Introduction: The Strategic Importance of Manufacturer Selection

Selecting the right compression socks manufacturer represents a decision with profound implications for your business success in the rapidly expanding medical and athletic compression wear market. As compression therapy continues gaining mainstream acceptance for both medical management and performance enhancement, the technical requirements for effective products have increased dramatically—creating clear distinctions between manufacturers capable of producing genuinely therapeutic garments versus those delivering merely cosmetic compression effects. This comprehensive guide explores the critical factors to consider when evaluating potential compression socks manufacturers, from technical production capabilities and compliance requirements to business reliability and ethical considerations. Whether you’re a medical supplier, athletic brand, or retailer entering this specialized market, understanding these evaluation criteria will help you establish manufacturing partnerships that deliver consistent quality, regulatory compliance, and reliable service. By approaching manufacturer selection as a strategic business decision rather than a simple procurement exercise, you can create sustainable competitive advantages through product efficacy, consistent quality, and reliable supply chains essential for success in the increasingly regulated and scientifically validated compression therapy market.

Understanding Compression Sock Manufacturing

Precision in Graduated Compression

True graduated compression socks apply decreasing pressure from the ankle upward—typically measured in mmHg—to support circulation. Producing this effect requires advanced knitting machinery with digital tension control, not just stretchy yarns. Reliable compression sock manufacturers use circular knitting machines that create targeted pressure zones, ensuring both comfort and clinical effectiveness. Material choices also matter: moisture-wicking yarns with controlled elasticity help maintain compression over extended wear without causing discomfort. Partnering with a manufacturer that understands these technical demands ensures your products deliver the expected therapeutic benefits—not just tight-fitting socks labeled as compression.

Yarn Composition and Technical Construction

A high-quality compression sock isn’t made by guesswork. Manufacturers specializing in compression hosiery use fiber blends engineered for function: nylon-spandex blends for stretch and durability, cotton or bamboo layers for comfort and breathability. The construction includes reinforced heel zones and graduated tension panels. Understanding how these elements affect fit, durability, and compression stability helps businesses select manufacturers with genuine medical textile expertise.

Regulatory Compliance in Key Markets

Compression socks marketed with medical claims often require regulatory approval. In the U.S., that may mean FDA registration; in Europe, CE marking. Leading manufacturers comply with ISO 13485 for medical devices and test their socks using standards like RAL-GZ 387. These certifications show the manufacturer can consistently produce safe, verified products—crucial for businesses selling into healthcare or pharmacy channels. A supplier familiar with regional regulations reduces compliance risks and ensures your brand meets both safety standards and customer expectations.

| Key Area | Details |

|---|---|

| Compression Technology | Graduated pressure (mmHg), circular knitting, digital tension control |

| Materials Used | Nylon-Spandex (stretch & support), Cotton/Bamboo (comfort & breathability) |

| Technical Features | Reinforced heel, targeted tension zones, moisture-wicking fibers |

| Certifications | ISO 13485, FDA (U.S.), CE (EU), RAL-GZ 387 for pressure accuracy |

| Regulatory Focus | Required for medical claims in healthcare, pharmacy, and export channels |

Evaluating Manufacturing Capabilities

Compression Sock Production Technology

When assessing a compression socks manufacturer, the first thing to examine is their equipment. Specialized circular knitting machines are essential for producing true graduated compression, not just tight socks. These machines feature precise tension control and enable zone-specific pressure—critical for therapeutic-grade compression socks. Unlike standard hosiery producers, medical compression sock manufacturers invest in pressure testing tools to validate PSI levels during and after production. Look for factories that can produce multiple compression zones in one sock—this signals advanced capabilities and supports custom design requests.

Compression Sock Material Expertise

Materials directly affect both comfort and compression accuracy. Top-tier compression sock suppliers understand the difference between everyday elastic yarns and functional blends made for compression therapy. They often use microfiber nylon, elastane with high stretch recovery, and moisture-wicking fabrics that maintain consistent pressure even after repeated washes. Manufacturers with in-house testing for compression loss, wash durability, and skin safety show greater product accountability. If your socks target athletes or medical users, material choices like temperature-regulating yarns or anti-bacterial finishes can set your brand apart. A knowledgeable factory can advise on the best combinations for specific needs, rather than just following basic specs.

Quality Assurance Systems

Compression Accuracy Testing

Top compression sock manufacturers go beyond surface-level quality checks by using advanced pressure testing systems. These systems measure compression levels at key leg zones to ensure socks deliver consistent pressure—typically within ±3 mmHg of intended ratings. Instead of relying only on machine settings, high-end factories verify compression during and after production using calibrated equipment. Accurate pressure is vital for medical and sports use, where actual therapeutic benefits depend on verified performance.

Run-to-Run Consistency

Consistency across production batches ensures that compression socks feel and perform the same every time. Trusted manufacturers document every production parameter—yarn tension, machine settings, heat-setting processes, and packaging protocols—to eliminate variation. Statistical process controls and batch traceability systems help catch problems early, reducing risk and improving quality control. Some brands even use digital color-matching tools for exact shade matching, critical in hospitals or clinics where compression levels may be color-coded.

Calibrated Quality Monitoring

Regular calibration of test equipment is another key feature of high-quality manufacturers. Factories that invest in pressure sensors, spectrophotometers, and certified testing tools offer higher assurance that your product meets precise standards. Calibration records provide transparency, giving brands confidence that test results reflect true product performance—essential for therapeutic-grade socks.

Choosing the Right Manufacturer

Evaluating quality assurance systems can reveal a manufacturer’s professionalism. Those with documented procedures, reliable test data, and transparent records tend to produce more dependable socks. Whether for medical, athletic, or travel use, consistent compression and batch reliability are essential to protecting your brand’s reputation and meeting user expectations.

| Quality Focus Area | Key Practice | Benefit |

|---|---|---|

| Compression Accuracy | Calibrated pressure testing (±3 mmHg tolerance) | Ensures true therapeutic effect |

| Batch Consistency | Documented production settings & traceability | Reliable fit and feel every time |

| Equipment Calibration | Routine calibration of testing tools | Accurate, repeatable test results |

| Color Matching | Digital shade matching tools | Maintains visual and code uniformity |

| Data Transparency | Available test reports & records | Builds brand trust and compliance |

Customization Capabilities

Compression Level Engineering

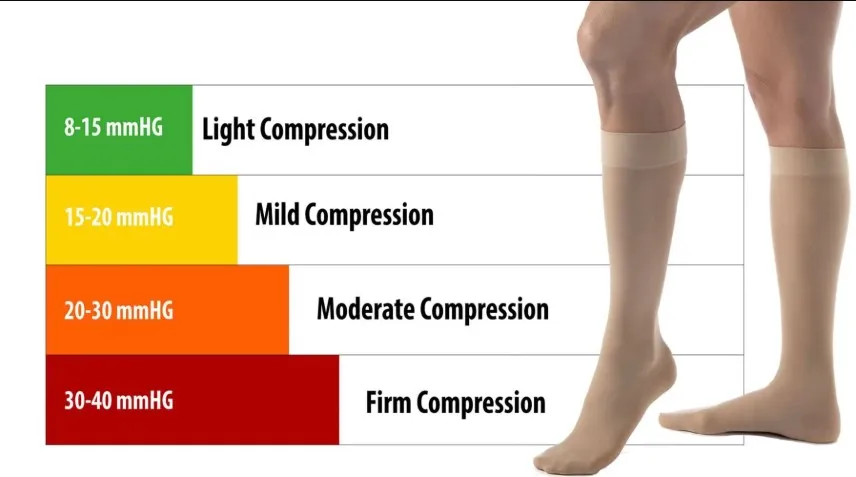

High-quality compression sock manufacturers stand out by their ability to deliver accurate and consistent pressure levels—especially in categories like 15–20 mmHg, 20–30 mmHg, and 30–40 mmHg. Advanced suppliers don’t just tweak elastic—they engineer socks using zoned pressure mapping to ensure the right compression at the calf, ankle, or foot. This matters in medical, athletic, or post-surgical applications where precision is non-negotiable. Manufacturers with reliable pressure grading across all sizes also help ensure the compression stays therapeutic—no matter the wearer’s leg circumference.

Application-Specific Design

Top factories tailor compression socks to fit different end uses. Athletic styles focus on muscle stabilization and blood flow, while recovery socks prioritize gradient pressure for circulation. Leading manufacturers often support collaborative development of new use-case products, combining performance fibers, reinforced zones, and pressure calibration to meet specific customer or market needs. This is especially important when entering niches like maternity, elderly care, or travel retail.

Branding and Retail Readiness

Private Label & Small-Batch Flexibility

Today’s compression sock suppliers understand the importance of brand identity—especially for startups, specialty clinics, or wellness retailers aiming to stand out in a competitive marketplace. Reliable manufacturers now support full-spectrum branding customization. This includes integrating custom logos directly into the sock design, adding woven or heat-transfer labels, and using pantone-specific yarns to match brand color guidelines. These capabilities are no longer reserved for high-volume buyers. Many manufacturers now accommodate small minimum order quantities (MOQs), typically between 300 and 1,000 pairs, depending on the sock type and complexity. This makes it practical for smaller brands to test limited designs, pilot private label programs, or respond to seasonal trends without tying up excessive inventory or cash flow. This small-batch flexibility empowers businesses to move quickly with market feedback and release capsule collections or clinic-specific SKUs at manageable scale.

Retail Packaging Optimization

Beyond product quality and fit, retail success depends on how the socks are presented to end consumers. Compression sock suppliers with in-house packaging capabilities allow brands to offer professional retail-ready presentation without outsourcing. Custom packaging options include recyclable printed sleeves, hook-and-hang display headers, and medical-grade carton inserts with compression level indicators and instructions. Barcode integration, QR code printing, and multilingual labeling can also be added to meet local retail compliance or e-commerce fulfillment needs. Some manufacturers even support digital printing, enabling smaller production runs without sacrificing packaging design flexibility.

Together, these branding and packaging services ensure your compression socks not only deliver performance but also reflect your brand image accurately. For any company aiming to grow through private label sales, clinical distribution, or retail channels, choosing a supplier with turnkey retail readiness is a practical step toward long-term success.

Business Reliability Factors

Compression Manufacturing Expertise

When choosing a compression sock supplier, manufacturing specialization is critical. Suppliers with years of experience in medical compression socks understand the importance of accurate pressure gradients, comfortable fabric blends, and performance over extended wear. These suppliers often refine their production through clinical feedback and precise quality control, leading to better durability and wearer satisfaction. Reviewing their portfolio, certifications, and history in therapeutic sock production offers insight into their expertise. Manufacturers with dedicated compression lines—not just general hosiery—are more likely to meet performance expectations for medical or wellness markets.

Industry Knowledge and Regulatory Awareness

Manufacturers who regularly work with healthcare distributors or supply to hospital networks often demonstrate deeper knowledge of compliance standards. This includes familiarity with international testing protocols, labeling requirements, and medical certifications. Participation in medical trade shows or collaboration with physiotherapists and clinics signals that the manufacturer is aligned with the needs of health-conscious end users. This background helps reduce errors in product specs, ensuring socks meet clinical performance expectations across different regions and use cases.

Financial and Operational Stability

A compression sock manufacturer’s financial health directly impacts fulfillment reliability. Long-standing businesses (ideally with 5+ years of continuous operation in this field) typically maintain the infrastructure, skilled labor, and equipment required for consistent quality and timely delivery. Stability indicators include evidence of reinvestment—such as factory upgrades, expanded machinery, or sustained headcount. Diverse customer portfolios across retail, wellness, and medical sectors also suggest resilience against market shifts. Prioritizing financially sound suppliers helps prevent supply chain disruptions, particularly when quality and delivery consistency are essential to your brand’s reputation.

Compliance and Documentation

Medical Device Registration Readiness

When compression socks are used for medical or therapeutic purposes, registration and regulatory compliance are not optional. Top-tier manufacturers are familiar with FDA registration (USA), CE marking (EU), and TGA approval (Australia). These factories handle classification differences, technical files, and clinical summaries aligned with ISO 13485—not just ISO 9001. Their systems support safe, compliant entry into hospitals, pharmacies, and reimbursed care channels. For brands targeting medical markets, this level of regulatory preparedness is essential to avoid non-compliance risks.

Product Testing and Technical Evidence

Reliable compression sock manufacturers back up their performance claims with lab-tested data. They verify compression levels, pressure gradients, biocompatibility, and wash durability according to recognized testing protocols. Leading factories offer documentation from third-party labs to confirm results, rather than relying solely on in-house testing. Certifications like OEKO-TEX® and independent pressure validation offer added credibility in both consumer and clinical markets. These records are vital for brands needing evidence to support product claims or enter regulated channels.

Certification Support for Global Markets

In addition to testing, manufacturers should provide necessary export documents and market-specific compliance paperwork. Whether targeting North America, Europe, or Asia, strong documentation—including quality declarations and labeling guidance—ensures smoother customs clearance and legal retail operations. This support is critical for medical distributors, insurers, and retail buyers demanding proof of regulatory adherence.

Ethical and Sustainability Considerations

Fair Labor Standards and Workplace Conditions

In today’s healthcare and wellness markets, fair labor practices are a baseline requirement when selecting a compression sock manufacturer. Buyers—especially from medical institutions and large retailers—expect not only consistent product quality but also responsible sourcing. Our company, Hangzhou Zhongzhi Industry Co., Ltd., established in 2010 and headquartered in Hangzhou, is built on ethical operations and long-term relationships. Our wholly-owned factory, Jiaxing Max Hosiery Co., Ltd., employs over 120 skilled workers and complies with rigorous international labor standards.

We proudly maintain BSCI certification, confirming our adherence to safe working conditions, legal wages, and a transparent employment structure. This includes fair working hours, workplace safety programs, and the absence of child or forced labor. Independent third-party audits are welcomed, and our operations remain open to facility inspections by prospective partners. We go beyond compliance by implementing skills development programs and a stable employment structure, leading to low turnover and consistent product quality.

For buyers prioritizing brand integrity and long-term supply chain reliability, our commitment to ethical labor standards ensures peace of mind and reduced reputational risk in a climate of growing transparency demands.

Sustainable Materials and Environmental Practices

Environmental responsibility is integrated into both our production methods and material choices. Our Jiaxing facility implements waste reduction, optimized energy use, and water management systems designed to reduce environmental impact. We are ISO 14001-ready and maintain OEKO-TEX® Standard 100 certification to ensure textile safety and low chemical usage.

We also offer recycled yarns, organic cotton, and other low-impact material alternatives without compromising performance—critical for compression sock applications where durability and elasticity matter. Eco-conscious clients will appreciate our use of minimal, recyclable packaging as part of our green logistics approach. For markets requiring compliance, we also hold FDA and CE certifications to ensure regional regulatory alignment.

By choosing a compression sock manufacturer with integrated sustainability and ethical compliance, buyers not only meet today’s supply chain expectations—they gain a trusted, value-aligned partner ready to support long-term brand growth in a competitive wellness landscape.

Conclusion: Building Strategic Manufacturing Partnerships

Selecting the right compression socks manufacturer represents a strategic decision that extends far beyond simple product procurement. By thoroughly evaluating manufacturing capabilities, compliance infrastructure, business reliability, and ethical practices, you can establish partnerships that deliver consistent quality, regulatory compliance, and reliable service aligned with your specific business requirements. This comprehensive approach to manufacturer selection helps avoid the common pitfalls of inconsistent quality, compliance issues, and delivery delays that undermine both customer satisfaction and profitability in the specialized compression therapy market.

The most successful manufacturing relationships evolve from transactional interactions into strategic partnerships where both parties invest in mutual success through collaborative development, transparent communication, and aligned business objectives. By applying the evaluation criteria outlined in this guide, you can identify manufacturers whose capabilities and business approaches complement your specific needs, whether you’re a medical supplier requiring strict compliance documentation, an athletic brand developing performance-focused compression, or a retailer creating exclusive compression lines for specific market segments. This thoughtful selection process creates the foundation for long-term relationships that deliver value beyond individual transactions, supporting your broader business objectives through reliable access to quality products that meet both regulatory requirements and customer expectations in the increasingly sophisticated compression therapy market.

FAQ Section

What’s the usual minimum order for custom compression socks?

Most manufacturers set MOQs between 300–1,000 pairs, depending on design complexity and compression level. Standard items may allow smaller runs with simple branding.

How long does production take from design to delivery?

Timelines range from 4–12 weeks. Lower compression levels are quicker, while medical-grade (20+ mmHg) styles take longer due to testing and compliance.

Which certifications should I look for?

Important ones include ISO 13485, FDA, CE, and OEKO-TEX®. For precise compression standards, look for RAL-GZ 387 and documented pressure testing.

How can I confirm compression accuracy?

Ask for third-party test reports, in-house testing procedures, and sampling options. Standards like CEN/TR 15831 and RAL-GZ 387 ensure pressure consistency.

What are common payment terms?

Typically 30–50% upfront, with balance before shipment. Long-term partners may offer net-30 terms. Reputable suppliers use secure, traceable payment channels.