Introduction to Compression Socks Manufacturing

Market Overview

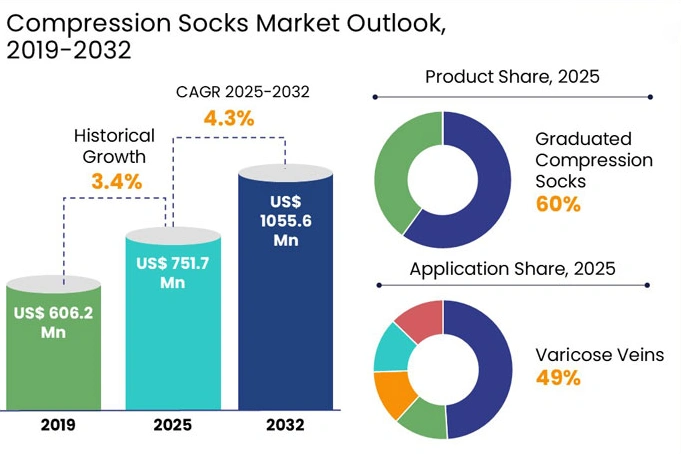

The global compression socks market is growing, driven by demand in healthcare, sports, and fashion. Suppliers range from small workshops to large, integrated factories. As you compare options, note production capacity, lead times, and minimum order quantities. A clear sense of market trends—such as antimicrobial yarns or moisture-management finishes—helps you discuss innovations with potential partners.

Importance of a Reliable Manufacturer

Your manufacturer is more than a supplier. They shape product quality, brand reputation, and customer satisfaction. A reliable partner delivers consistent compression levels, precise sizing, and sturdy construction. Their facility should handle fabric sourcing, knitting, dyeing, and finishing under one roof. Vertical integration reduces communication gaps and cuts turnaround times.

Common Sourcing Challenges

Many buyers face unclear pricing structures, hidden fees, and shifting lead times. Language barriers can delay technical clarifications. Some factories lack robust quality-control systems, resulting in inconsistent pressure gradients or weak stitching. Establish clear expectations early—request detailed quotes, sample runs, and documented production schedules. That upfront work prevents costly mistakes later.

Advantages of Working with a Direct Factory

Cost Efficiency

Direct factories eliminate middle-man markups. You negotiate pricing based on raw materials and labor costs, not distributor premiums. Lower unit costs free budget for design enhancements or marketing. When order volume grows, you can renegotiate tiered pricing to capture further savings.

Faster Communication

Working directly with factory managers speeds up decision-making. You exchange measurements, material specs, and packaging designs without relays. Quick feedback loops allow you to adjust samples or resolve production issues in real time, reducing delays.

Greater Flexibility

Direct partnerships unlock customization—everything from yarn blends to branded labels. Factories can adapt knitting patterns, adjust compression gradients, or test new finishes on small pilot runs. That agility empowers you to respond to client feedback and seasonal trends without waiting for third-party approvals.

Product Range and Customization Options

Compression Levels and Styles

A top manufacturer offers a spectrum of mmHg ranges—light (15–20), medium (20–30), and firm (30–40)—plus open- and closed-toe options. They supply knee-high, thigh-high, and full tights. You’ll find sporty mesh-inset sleeves, medical-grade stockings, and everyday styles that blend support with aesthetic appeal.

Material Choices

Look for factories that work with microfiber, nylon-spandex blends, copper-infused yarns, and moisture-wicking finishes. They should offer Oeko-Tex or similar certifications to guarantee yarn safety. Requests for antimicrobial or gel-infused variants should be feasible without huge minimums.

Branding and Packaging

Customization extends to logos, label placement, and retail packaging. Factories often handle hang-tags, custom boxes, and multi-pair polybags. Ask about minimum order quantities for branded inserts or custom colorways to ensure your products stand out on shelves or in e-commerce listings.

Quality Control and Certifications

In-House Testing Protocols

A robust QC system checks compression levels at every stage. Manufacturers should use calibrated pressure gauges to verify graduated strength (mmHg) across sample panels. They also inspect seam integrity, stitch density, and material weight to meet your specifications on every unit.

International Certifications

Leading factories hold ISO 9001 for quality management and Oeko-Tex Standard 100 for textile safety. Medical-grade lines may require FDA registration or CE marking, depending on target markets. Confirm that your partner can provide up-to-date certificates and support compliance audits.

Audit Transparency

Transparent factories welcome third-party audits, whether by your own team or an independent inspector. They maintain digital records—production logs, fabric lot tracking, and QC reports—to make traceability simple. This level of openness reduces risk and builds confidence in long-term collaboration.

Supply Chain Management

Raw Material Sourcing

An effective manufacturing partner maintains strong relationships with reliable yarn and fiber suppliers. They secure high-quality raw materials like microfiber, nylon-spandex blends, and copper-infused yarns well in advance of production. By vetting suppliers for certification—such as Oeko-Tex Standard 100—they guarantee fibers that meet safety and performance benchmarks. Consistent raw material availability prevents production delays and ensures every batch of compression socks maintains the same feel, strength, and compression profile you expect.

Inventory Control

Keeping the right balance of raw materials, work-in-progress, and finished goods is critical. Top factories use real-time inventory management systems that track stock levels at every stage. As yarns arrive, they’re logged and stored under optimal conditions—temperature, humidity, and cleanliness—to preserve elasticity and color. During knitting and finishing, scanned barcodes record movement through the line. Finished socks receive batch numbers and are staged for inspection before shipping. This disciplined approach minimizes waste, prevents shortages, and lets you plan launches with confidence.

Risk Mitigation

Unexpected disruptions—factory downtime, supplier issues, or transport delays—can cripple schedules. Leading manufacturers build buffers into their supply chain: multiple vetted suppliers for key yarns, secondary dye houses for color matching, and contingency plans for alternate transport routes. They conduct regular risk assessments to identify potential bottlenecks and maintain emergency reserves of critical components. By actively monitoring global logistics trends and geopolitical developments, they react quickly to keep production moving even when challenges arise.

Lead Times & Logistics

Production Scheduling

A clear production plan starts with a detailed project timeline. Your factory partner will map out every step—from yarn procurement and sample approval through knitting, dyeing, and quality control—to final packaging. Milestones are established for sample returns, bulk runs, and inspections. Frequent check-ins ensure the schedule stays on track and that any required adjustments—such as minor design tweaks—are incorporated without derailing the overall timeline.

Shipping Coordination

Once compression socks pass final inspection, they move into logistics planning. Experienced manufacturers coordinate with freight forwarders to optimize door-to-door transit. They select carriers based on cost, reliability, and transit time, choosing air, sea, or ground transport as appropriate. Proper customs documentation, HS codes, and labeling reduce the risk of customs delays. Tracking tools let you monitor shipments in real time, giving peace of mind that your products are en route and allowing you to prepare for smooth delivery to your warehouse or distribution center.

Traceability and Transparency

From yarn bale to boxed carton, traceability is essential. Each batch of socks carries a lot code that links back to raw material certificates and production logs. Should any issue arise—say, a yarn lot shows color variance or elasticity concerns—you can pinpoint its origin and address it swiftly. Transparent factories share these records through secure portals, so you always understand the status of orders, inspections, and shipping, eliminating guesswork and fostering trust.

Sustainability and Ethical Practices

Eco-Friendly Materials

Modern brands and consumers increasingly prioritize sustainability. Leading compression sock manufacturers offer recycled or renewable yarn options—such as recycled nylon or bio-based spandex—that reduce environmental impact without sacrificing performance. Some partners even collaborate on closed-loop recycling programs, taking back used socks to repurpose fibers into new yarns. By choosing eco-friendly materials, you align your brand with responsible practices and appeal to eco-conscious customers.

Fair Labor Standards

Ethical manufacturing isn’t just about materials; it’s about people. A reputable factory model enforces fair wages, reasonable working hours, and safe conditions on-site. Regular social audits by independent bodies verify compliance with labor laws and international labor standards. When partnering with such a manufacturer, you can credibly communicate your supply chain ethics to retailers, health institutions, and end users.

Waste Reduction and Energy Efficiency

Producing compression socks generates offcuts, dye effluent, and energy use. Progressive facilities implement waste-minimization strategies—recycling offcuts into insulation or stuffing, treating and reusing water in dye houses, and capturing heat energy from machines. On the energy front, some factories install solar panels or high-efficiency LED lighting to lower their carbon footprint. Partnering with a manufacturer committed to sustainable operations helps your business reduce environmental impact and meet any corporate social responsibility goals.

Technical Innovation and Support

Automated Knitting Technology

State-of-the-art knitting machines deliver precision and speed. Automated looms can produce complex compression gradients and zoned support areas with programmable patterns. This technology ensures each sock meets your specified mmHg profile without manual intervention. Faster setup times mean sample runs happen quickly, and production scales smoothly when volumes increase.

Custom Design Software

Leading factories use specialized software to translate your design files into machine-readable patterns. You upload your desired knit structure, compression map, and color layout, then preview realistic renderings before any yarn is touched. This digital workflow accelerates sample approvals and minimizes errors, so the first bulk run closely matches your vision.

Technical Consultation and Testing

Beyond manufacturing, a strong partner offers technical expertise. In-house engineers and textile scientists guide you through compression selection, fabric blends, and durability testing. They can run lab tests—tensile strength, pressure retention over wash cycles, colorfastness—to validate performance claims. Armed with this data, you can confidently market your products with verifiable specifications and reassure healthcare or athletic clients of their efficacy.

Regulatory Compliance and Documentation

Approvals and Standards

A reputable compression socks manufacturer adheres to international standards governing medical textiles and personal protective equipment. Look for partners whose facilities and products meet ISO 13485 for medical device quality management, as well as Oeko-Tex Standard 100 for textile safety. These certifications confirm that the factory maintains stringent process controls, from raw material testing through final product inspection. For markets like North America and Europe, FDA registration or CE marking may also be required for medical-grade compression wear. Working with a compliant manufacturer ensures your products can enter regulated channels—hospitals, clinics, and pharmacies—without legal hurdles.

Labeling Requirements

Correct labeling is vital for both regulatory compliance and end-user guidance. Compression socks must display the mmHg rating, size chart, fiber content, care instructions, and any warnings (e.g., “Consult a physician before use if you have diabetes”). Manufacturers familiar with major markets will apply compliant hangtags and woven labels during final assembly. They can also supply multilingual instructions and barcoded packaging to meet diverse retail requirements. Clear, accurate labeling protects your customers and strengthens trust in your brand.

Documentation for Customs and Import

Global distribution involves customs paperwork, certificates of origin, and possibly certificates of analysis for certain fiber treatments (like antimicrobial finishes). A well-organized factory provides digital packing lists, commercial invoices, and export licenses where needed. They may even prepare phytosanitary certificates if natural fibers are involved. Having these documents handled correctly prevents delays at ports and avoids unexpected duties or inspections. Transparency in documentation also simplifies audits for your import compliance team.

After-Sales Support and Quality Assurance

Warranty and Repair Programs

Even high-quality compression socks can experience issues—loose seams, color fading, or compression loss. Top manufacturers back their products with warranties that guarantee performance for a set period or number of wash cycles. Some offer repair services for minor defects, extending the usable life of samples or retail returns. A clear, factory-supported warranty policy gives you confidence when presenting products to distributors or end customers.

Reorder Flexibility

Your needs may evolve: seasonal colors, new compression levels, or updated packaging design. Choose a manufacturer offering flexible reorder processes. They should keep your past specifications on file and allow you to tweak details—yarn blend, knit density, label style—without starting from scratch. Fast reorders with consistent quality help you maintain inventory levels and respond to market trends efficiently.

Customer Feedback Loops

Manufacturers who value long-term partnerships invite structured feedback. After a production run, they gather data on defect rates, delivery performance, and end-user satisfaction. Regular review meetings identify areas for improvement—whether it’s tightening QC thresholds, testing new compression profiles, or adjusting package labels. This iterative approach ensures continuous product enhancement and cements your role as a strategic partner, not just a customer.

Customer Service and Communication

Dedicated Account Management

Working directly with a factory means you should have a single point of contact—an account manager who understands your brand, order history, and technical requirements. This person coordinates sample approvals, production schedules, and shipping logistics. They expedite responses to queries, troubleshoot issues in real time, and keep you informed at every milestone.

Multilingual Support

Global brands need clear communication in multiple languages. Leading factories staff multilingual teams—English, Spanish, French, German, and more—to ensure technical specifications and contract terms are fully understood. This capability reduces misinterpretations and accelerates the development cycle, especially for custom projects involving precise compression maps.

Collaboration Platforms

Modern manufacturers leverage digital platforms where you can review knitted samples via high-resolution images, track production progress on interactive dashboards, and access QC reports instantly. Some even provide integrated chat functions, video-conference links for virtual factory tours, and cloud repositories for design files. These tools streamline collaboration, maintain version control, and create an audit trail for every decision.

Future Trends in Compression Sock Manufacturing

Smart Textiles and Wearables

The next wave in compression wear merges sensors and conductive yarns into the fabric. Smart socks can monitor circulation, track swelling patterns, or even link to mobile apps for real-time feedback on wearer comfort. Manufacturers investing in R&D partnerships with tech firms will lead this innovation, creating products that transition from passive support to active health monitors.

3D Knitting and On-Demand Production

3D knitting machines allow seamless, fully fashioned socks with minimal waste. Combined with digital knitting files, they enable on-demand manufacturing—producing small batches or individual pairs tailored to exact measurements. This model reduces inventory, supports mass customization, and shortens lead times, benefiting brands that want rapid turnaround or direct-to-consumer models.

Biodegradable and Renewable Fibers

Sustainability goes beyond recycled nylon. Research is underway on biodegradable compression yarns made from plant-based polymers. These fibers maintain elasticity while breaking down naturally at end-of-life. Factories that pilot renewable fiber blends and invest in biodegradable packaging will meet growing consumer and regulatory pressure for circular textile solutions.

Conclusion

Choosing the right compression socks manufacturer sets the foundation for product quality, customer satisfaction, and brand growth. By evaluating factors such as material expertise, production transparency, and technical support, you ensure your line meets market demands and regulatory standards. A strong partnership streamlines development, reduces risks, and delivers consistent performance.

While emerging trends—like smart textiles and on-demand 3D knitting—offer exciting possibilities, proven practices remain essential. Prioritize factories with robust QC protocols, sustainable sourcing, and clear communication. That balance of cutting-edge capability and dependable processes keeps your brand competitive today and adaptable for tomorrow’s shifts.

Now that you understand the manufacturing landscape—from raw materials and compliance through after-sales support and future trends—it’s time to act. Reach out to potential partners with detailed specifications, request samples, and review their technical documentation. A methodical approach leads to a reliable supply chain and a product your customers will trust.

FAQ

How do I verify a manufacturer’s compression accuracy?

Check for calibrated pressure-gauge test reports or ISO 9001/13485 certification demonstrating in-house compression testing.

Can I request small pilot runs before full production?

Yes. Most factories support sample batches or pilot runs to validate fit, feel, and compression levels without large commitments.

What certifications ensure fabric safety?

Look for Oeko-Tex Standard 100 for chemical safety and, if applicable, FDA registration or CE marking for medical-grade products.

How long does the typical development process take?

From material selection and sampling to final bulk production, timelines range from 6 to 12 weeks, depending on customization complexity.

What ongoing support can I expect after my order ships?

Reputable manufacturers offer warranties, repair or replacement services for defects, and flexible reorder processes to maintain consistent quality.