Introduction: The Rise of Personalization in Football Equipment

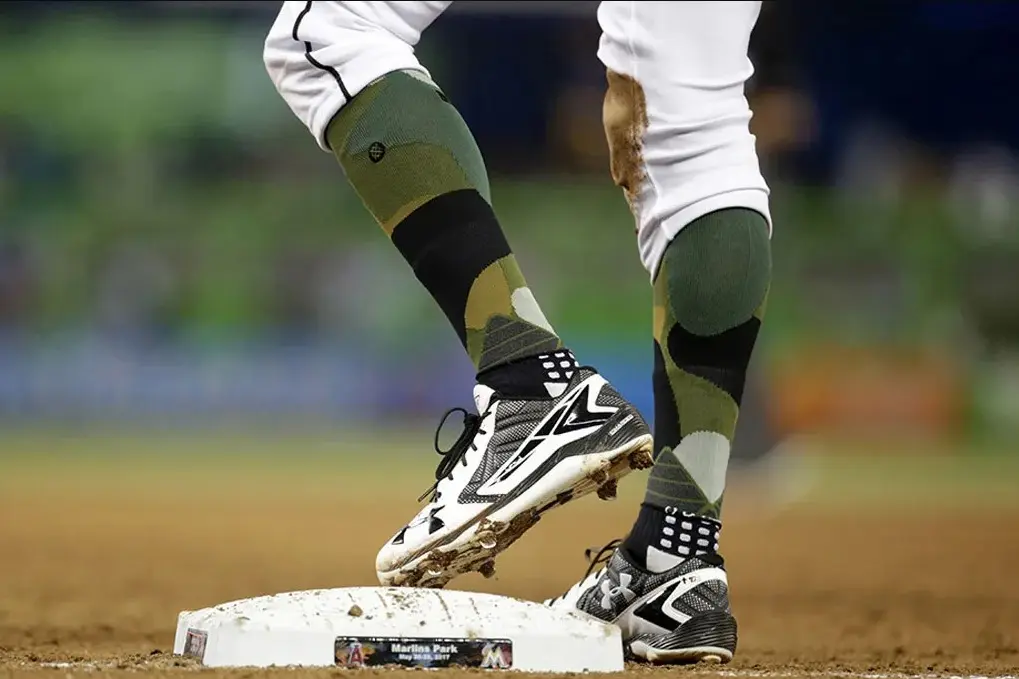

The evolution of football equipment has entered a new era of personalization, with custom football sleeves emerging as powerful expressions of both individual identity and team unity. What began as standard-issue gear has transformed into canvas for personal expression while maintaining crucial performance benefits. Today’s custom football sleeves represent the perfect marriage between athletic functionality and personalized aesthetics, allowing players to showcase their unique identities while benefiting from advanced performance technology. This comprehensive guide explores the multifaceted world of custom football sleeves, examining how personalization enhances both the psychological and physical aspects of player performance while creating distinctive team identities that resonate with players and fans alike.

The Performance Foundation of Custom Sleeves

Technical Benefits Beyond Personalization

While customization draws immediate attention, the foundation of every quality football sleeve remains its performance capabilities. Custom sleeves maintain all the technical benefits of standard options, including graduated compression that enhances circulation, muscle stabilization that reduces fatigue, and moisture management that keeps players comfortable in varying conditions. The customization process utilizes specialized techniques that preserve these functional elements while adding personalized features. This performance-first approach ensures that aesthetics never compromise the primary purpose of enhancing player capabilities on the field, making custom sleeves true performance equipment rather than mere fashion accessories.

Material Selection for Optimal Customization

The customization potential of football sleeves depends significantly on the base materials selected. Different fabrics accept personalization techniques with varying degrees of success while maintaining different performance characteristics. Polyester blends offer excellent color reproduction and durability for printed designs but provide moderate compression. Nylon-elastane combinations deliver superior compression and moisture management while accepting sublimation printing effectively. Some advanced materials from suppliers like Max Hosiery even incorporate antimicrobial properties that prevent odor development without interfering with customization processes. Understanding these material characteristics allows teams and players to select the optimal foundation for their specific performance needs and design ambitions.

Personalization Techniques and Options

Digital Printing Advancements

Digital printing technology has transformed football sleeve customization, delivering photorealistic designs with remarkable detail and color accuracy. Unlike traditional screen printing, digital printing is a non-contact process that preserves the fabric’s elasticity and compression properties, which are essential for athlete performance. This method enables complex gradients, photographic images, and detailed patterns that were once impossible to reproduce. Modern digital printers use specialized flexible inks that resist cracking, peeling, and fading, even after repeated washes and intense physical activity. The result is vibrant, durable designs that maintain their sharpness throughout an entire season, ensuring that team branding looks professional and consistent every game.

Sublimation: The Gold Standard for Durability

Sublimation printing remains the highest-quality option for football sleeve customization. This process infuses dye directly into polyester fibers by converting solid inks into gas under heat and pressure. This molecular bonding creates a permanent, edge-to-edge design that won’t crack, peel, or fade over time. Sublimation supports unlimited color complexity and photorealistic detail, making it perfect for team logos, intricate patterns, and custom numbers. Because the design becomes part of the fabric itself, sublimated sleeves maintain both their visual appeal and functional stretch throughout heavy use, providing athletes with comfort and style simultaneously.

Additional Customization Options

Beyond printing techniques, customization can include adding features like silicone grip bands, reflective elements for low-light conditions, and personalized sizing for optimal fit. These enhancements improve both the look and function of football sleeves. For instance, grip bands help sleeves stay securely in place during intense movements, reducing distractions and discomfort. Reflective details add safety for evening practices, while tailored sizing ensures compression benefits without restricting circulation. Combining these options with advanced printing techniques allows teams to create truly unique, high-performance sleeves that meet their specific needs.

| Customization Technique | Key Features | Benefits | Ideal Use Case |

|---|---|---|---|

| Digital Printing | Non-contact process, flexible inks, detailed design | Maintains fabric stretch, vibrant colors, durable | Complex gradients, photographic images, multi-color logos |

| Sublimation Printing | Dye infused into fabric fibers, permanent design | No cracking/peeling, edge-to-edge prints, highly durable | Photorealistic logos, full coverage patterns, long-lasting designs |

| Additional Customization Options | Silicone grip bands, reflective elements, personalized sizing | Improved sleeve grip, enhanced safety, better fit | Secure fit during play, low-light visibility, tailored comfort |

Team Identity Enhancement

Unified Visual Systems Through Customization

Custom football sleeves play a vital role in building a unified team identity that goes well beyond the basic uniform. When every player wears sleeves designed with matching colors, logos, or patterns, it creates a consistent visual flow that’s immediately recognizable by fans, commentators, and opponents alike. This coordinated appearance can include gradient color transitions reflecting official team colors, precise placement of team logos or player numbers for visual balance, and design details tailored to specific positions. Such deliberate customization helps present the team as a polished, professional unit, which can influence how competitors perceive them on the field and boost the team’s own confidence even before the game starts.

Psychological Benefits of Team Cohesion

Beyond looks, the psychological impact of custom sleeves is significant. Studies in sports psychology reveal that when players wear matching gear that highlights both the group and individual, it strengthens their sense of belonging and shared purpose. This feeling of unity fosters commitment and motivation, which are critical in high-pressure competitive environments. Personalized elements incorporated within a cohesive design framework allow players to feel recognized as individuals while still part of a collective. This balance nurtures healthy team dynamics and helps athletes perform at their best, driven by a deeper connection to the team and its goals.

Enhanced Fan Engagement and Brand Recognition

Custom sleeves also contribute to fan engagement and brand building. Fans often connect emotionally to distinctive team gear that reflects identity and pride. When teams showcase eye-catching, consistent designs through custom sleeves, it enhances merchandise appeal and strengthens brand loyalty. Engaged fans wearing matching apparel extend the team’s visual presence beyond the stadium, helping build community and expanding the team’s reach in local and digital spaces. This creates added value for teams and sponsors, making custom sleeves a strategic tool for growth on and off the field.

Individual Expression Within Team Frameworks

Number and Name Customization Approaches

Integrating player numbers and names into football sleeves is the most familiar and effective way to personalize gear while maintaining team identity. Today’s customization methods go beyond simple block fonts. Teams can choose from various typography styles that reflect their personality, such as bold modern fonts or sleek script styles. Placement options vary as well—numbers and names can be vertically aligned along the bicep for traditional appeal, wrapped horizontally around the forearm for visibility, or even placed diagonally to add visual energy. Some teams assign special formatting to leaders, such as captains’ numbers being larger or highlighted in different colors. These design choices make each player easily identifiable and subtly communicate roles, blending function with style.

Personal Achievement Recognition

Custom sleeves also provide a platform for recognizing individual accomplishments while upholding team unity. Adding small symbols—like championship stars, captain badges, or milestone markers—into the sleeve design celebrates personal success without compromising the overall aesthetic. Some teams adopt progressive customization programs where players earn additional sleeve elements based on performance or dedication. This not only highlights personal achievement but also fosters motivation and pride. By weaving individual stories into the team’s visual narrative, players feel both valued for their contributions and connected to a larger goal, reinforcing a positive team culture.

Balancing Individuality with Team Unity

While customization supports personal expression, it must be balanced with maintaining a cohesive team look. Consistency in color schemes, font styles, and placement ensures that individual elements don’t appear out of place. Coaches and designers collaborate to set clear guidelines that allow personalization without diluting brand identity. This balance helps players feel unique while presenting a unified front, which is essential for team spirit and external recognition. When done thoughtfully, customization strengthens both the individual’s confidence and the team’s collective presence on the field.

| Aspect | Description | Examples / Notes |

|---|---|---|

| Number and Name Customization | Various font styles and placements reflect team personality and player identity | Vertical on bicep, horizontal on forearm, diagonal designs |

| Leadership Identification | Differentiated number size or color for captains or key players | Larger or colored numbers to signify leadership |

| Personal Achievement Recognition | Incorporate symbols like stars or badges for milestones and championships | Championship stars, captain badges, record markers |

| Progressive Customization | Earned sleeve elements based on performance or milestones to motivate players | Additional design features unlocked through achievements |

| Balance Individuality & Unity | Consistent colors, fonts, and placement maintain team cohesion while allowing personal expression | Design guidelines ensure unity and unique player identity |

Design Considerations for Maximum Impact

Color Psychology in Custom Sleeve Design

Choosing colors for custom football sleeves goes beyond matching team logos and uniforms. Colors carry psychological weight that influences both players and their opponents. For example, red is often linked to increased energy, aggression, and dominance, which can boost player confidence and potentially intimidate rivals. Blue, on the other hand, is associated with calmness, reliability, and focus, helping players maintain composure under pressure. Many teams use these insights strategically—incorporating bold reds or blacks for home games to emphasize dominance and more neutral or calming colors for away games to maintain focus and resilience. Accent colors also play a role, subtly reinforcing the team’s identity while evoking desired emotional reactions.

Visibility and Recognition Factors

While style and psychology matter, custom sleeve designs must also prioritize visibility and quick recognition during gameplay. Contrast between sleeve colors and numbers or logos is critical to ensure players can be identified clearly by coaches, teammates, and officials from a distance. High contrast improves sideline communication and helps broadcasters capture clear images during fast-paced action. Reflective or fluorescent details are increasingly popular for enhancing visibility in low-light conditions or during evening matches. Moreover, some teams design sleeves with slight pattern variations or color codes that differentiate player positions or roles. This subtle differentiation speeds up player identification during intense moments, allowing coaches to make faster decisions and improve team coordination.

Production and Implementation Processes

From Design Concept to Finished Product

The journey from initial concept to game-ready custom football sleeves involves multiple specialized processes that maintain both design integrity and performance characteristics. Professional design development typically begins with digital mockups that visualize concepts on accurate sleeve templates, allowing for refinement before production commitment. Material selection follows, with considerations for both performance requirements and design compatibility. Production processes vary based on customization technique, with quality control checkpoints ensuring consistent compression properties alongside design accuracy. Final testing involves both visual inspection and performance evaluation, confirming that customized sleeves maintain all functional benefits while accurately representing design intentions.

Bulk Order Considerations for Teams

Team-wide implementation of custom football sleeves requires careful planning to ensure consistent quality and timely availability. Establishing accurate size distribution across the roster prevents shortages or excess inventory, while standardized measurement protocols ensure proper fit for all players. Production timelines must account for approval processes, manufacturing lead times, and buffer periods for potential adjustments. Many teams implement phased ordering systems that prioritize starter equipment while maintaining consistent design elements across primary and backup sets. These systematic approaches to team orders maximize value while ensuring all players receive properly fitted custom sleeves that deliver consistent performance benefits alongside unified team appearance.

Maintenance of Customized Equipment

Preserving Design Integrity Through Proper Care

Custom football sleeves require specific maintenance approaches to preserve both performance characteristics and design elements throughout their usable life. Washing in cold water with mild detergent protects both elastic properties and customization integrity, while avoiding fabric softeners prevents compression degradation. Turning sleeves inside-out during washing reduces friction on custom elements, extending design clarity and color vibrancy. Air drying is strongly recommended, as high-heat drying can damage both elastic components and certain customization types. These specialized care protocols ensure custom sleeves maintain their distinctive appearance alongside their performance benefits, delivering consistent value throughout multiple seasons of use.

Replacement Cycles and Design Continuity

Establishing appropriate replacement cycles for custom football sleeves balances equipment performance with budget considerations while maintaining design continuity. Most high-quality custom sleeves maintain optimal compression and design integrity for approximately 40-60 wearing cycles before requiring replacement. Teams should implement tracking systems that monitor usage frequency and washing cycles to anticipate replacement needs before performance degradation occurs. When implementing new designs, phased approaches that maintain core elements while evolving secondary features create visual continuity that strengthens brand recognition over time. This strategic approach to replacement cycles ensures consistent performance while allowing for design evolution that keeps team appearance fresh and engaging.

Future Trends in Sleeve Customization

Technology Integration Beyond Visual Elements

The next frontier in football sleeve customization extends beyond visual elements to incorporate functional technology that enhances both performance and communication. Emerging options include embedded RFID tags that track player movements and performance metrics during practice and games, providing valuable data for coaching staff. Some developmental systems incorporate subtle LED elements that can display changing information or respond to specific game situations. Near-field communication (NFC) capabilities are being explored to allow fans with compatible devices to access player statistics or exclusive content by scanning sleeve elements. These technology integrations represent the evolution from purely visual customization to functional enhancements that create new capabilities through personalized equipment.

Sustainability Approaches in Custom Equipment

Environmental consciousness is increasingly influencing custom football sleeve development, with sustainable approaches gaining prominence in both materials and processes. Recycled polyester derived from post-consumer plastic is becoming a viable base material that maintains performance characteristics while reducing environmental impact. Water-based inks and energy-efficient sublimation processes minimize chemical usage and carbon footprint during customization. Some forward-thinking programs implement end-of-life recycling programs where worn sleeves are collected and processed into materials for new equipment. These sustainability initiatives allow teams to maintain distinctive custom appearances while demonstrating environmental responsibility that resonates with increasingly eco-conscious players and fans.

Conclusion: The Personalized Performance Advantage

Custom football sleeves represent the ideal intersection of performance technology and personal expression, delivering functional benefits while creating distinctive visual identities for teams and individuals. The psychological advantages of personalization—including enhanced team cohesion, individual motivation, and confidence—complement the physical benefits of compression, stabilization, and protection. This combination creates a comprehensive performance advantage that extends beyond what standard equipment can provide, making customization a strategic choice rather than merely an aesthetic preference.

As customization technology continues advancing, the possibilities for distinctive, high-performance football sleeves will expand further, offering even more sophisticated options for teams seeking competitive advantages through equipment innovation. By understanding the performance foundations, design considerations, and maintenance requirements outlined in this guide, teams and players can make informed decisions about implementing custom sleeves that enhance both individual capabilities and collective identity. In the increasingly personalized world of sports equipment, custom football sleeves stand out as powerful tools that transform necessary gear into meaningful expressions of team culture and individual excellence.

If you’re ready to take your team’s performance and identity to the next level, explore our website at Max Hosiery. We specialize in fully customizable, high-quality socks and sleeves tailored to your exact specifications. Partner with us to design gear that fits perfectly, supports your athletes, and showcases your team’s unique spirit. Start your customization journey today with Max Hosiery — where function meets personal style.

FAQ Section

How do custom football sleeves affect performance compared to standard options?

Quality custom sleeves maintain identical performance benefits including compression, moisture management, and muscle stabilization, as the customization processes are specifically designed to preserve these functional properties while adding personalized visual elements.

What’s the typical price difference between standard and custom football sleeves?

Custom sleeves typically cost 15-30% more than standard options, with variables including customization complexity, quantity ordered, and production technique, though bulk team orders often reduce this premium through volume pricing.

How long do custom designs typically last before fading or cracking?

Sublimation-printed designs maintain original appearance for the life of the sleeve, while quality direct-printed designs should maintain 90% color vibrancy for approximately 30-40 wash cycles when proper care instructions are followed.

Can existing plain sleeves be customized after purchase?

Post-purchase customization is possible but limited, with heat transfer being the most common option for adding numbers or simple logos to existing sleeves, though results typically don’t match the durability or integration quality of sleeves customized during manufacturing.

What’s the minimum order quantity for custom football sleeves?

While individual customization is available through some retailers, team orders typically require minimum quantities of 10-15 pieces for cost-effective production, though some suppliers offer small-batch options with slightly higher per-unit pricing.