In today’s competitive market, many brands face high return rates and customer complaints due to poorly designed products that lead to foot fatigue. According to a survey by Running USA, nearly 60% of trail runners switch brands because of discomfort, contributing to a 15% rise in returns. When end users experience discomfort on rugged terrains, negative reviews and lost loyalty quickly follow. You can overcome these challenges by investing in improved design and quality features that directly address these pain points. This article outlines how thoughtful innovation not only reduces returns and enhances customer satisfaction but also drives long-term business growth. Discover actionable insights to transform your product line and set your brand apart in a demanding market.

Core Features of High-Performance Trail Running Socks

When you work to improve your product line, every detail is important. A well-designed product can reduce foot fatigue, lower return rates, and lead to happier end customers. Focusing on these key features helps you offer a standout product that builds your brand’s reputation.

Moisture-Wicking Materials: Keeping Feet Dry

You need fabrics that quickly remove sweat from the skin. Advanced materials keep feet dry during long runs, reducing discomfort and fatigue. This simple upgrade can enhance customer satisfaction and give your product a clear advantage.

Strategic Cushioning Zones for Your Trail Running Sock

Place cushioning in critical areas like the heel and forefoot. This design helps absorb impact on rough trails and provides the support your customers need. By addressing these areas, you reduce strain and extend product durability.

Seamless Construction: Eliminating Blisters

A seamless design minimizes friction and lowers the risk of blisters and irritation. By ensuring a smoother fit, you offer a product that enhances comfort during prolonged use. Consider partnering with a reliable manufacturing facility to customize these features and meet market demands.

The Anatomy of a Trail Running Sock Built to Last

When you build a quality product, each detail plays a role in its longevity. Focusing on durable design means you deliver a product that end users can rely on, even in challenging conditions.

Targeted Reinforcements: Toe Caps, Heel Grips, and Arch Support

You can boost durability by reinforcing key areas. Strengthened toe caps reduce the risk of wear, secure heel grips keep the sock in place, and proper arch support adds extra stability on uneven ground. This approach helps extend the life of your product and meets the high standards of demanding customers.

Anti-Odor Technology: Fresh Mile After Mile

You should consider anti-odor treatments to maintain a clean, fresh product. Using materials that prevent bacterial growth keeps the sock free from unwanted smells, ensuring comfort over long distances. This feature makes your product more appealing and encourages repeat business.

Compression Benefits: Reducing Muscle Strain for Long-Distance Runners

You can also enhance performance by adding gentle compression. This feature supports blood circulation and helps lessen muscle strain during extended activity. By incorporating compression, you offer a product that aids recovery and meets the needs of long-distance runners.

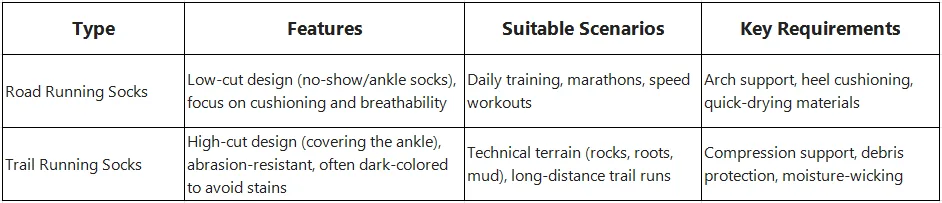

Road vs. Trail: Comparing Running Sock Types

When you explore different designs, you notice key differences between road-focused and off-road options. Road models usually feature a low-cut design for enhanced breathability and light cushioning, ideal for smooth surfaces. In contrast, items meant for rugged conditions include extra reinforcements and improved moisture control to handle uneven terrain. This clear distinction helps you decide which features to emphasize when expanding your product line for various training needs.

How Brands Can Reduce Returns with Trail Running Sock Innovation

Savvy brands don’t wait for complaints—they engineer resilience into every stitch. Focusing on three strategic areas can minimize returns while building trust with trail runners.

- Rugged Terrain Testing: Simulating Real-World Abuse

You gain a competitive edge by stress-testing beyond lab conditions. Partner with factories that replicate steep ascents and jagged rocks to expose weaknesses in materials and seams. For example, prototyping under simulated rough terrain helps identify premature wear zones before mass production.

- Precision Fit Systems: Ending One-Size-Fits-All

Universal sizing ignores biomechanical diversity. You reduce slip-induced blisters—the top return driver—by offering gender-specific lasts and half-sizes. Tailored arch support and ankle coverage also ensure a snug fit for varied foot shapes, enhancing comfort on uneven trails.

- Educate to Elevate: Care Guides That Build Trust

Poor maintenance shortens product lifespans. Embed clear wash instructions (e.g., “cold water only”) on packaging or via QR codes. Educated customers preserve cushioning and elasticity, reducing complaints about “flattened” or “stretched-out” socks.

- Give Purchase Suggestions for Your Customers

When you plan your offerings, consider the diverse needs of your market. For everyday use on roads, opt for lightweight, low-profile designs that prioritize comfort and breathability. For more demanding conditions, choose products with added durability and support. Evaluate material choices such as Merino wool for its natural warmth and moisture management, or synthetic fibers for quick drying. Offering a range of price points lets you cater to different customer segments while demonstrating the unique benefits of your customized products.

- Precautions for Maintaining Sock Quality

When you deliver high-quality products, guiding customers on proper care is essential. Advise them to gradually break in new items during training sessions for the best fit. Recommend gentle washing methods and avoiding high temperatures to preserve fabric quality. By providing clear maintenance guidelines, you help extend the life of your product, reduce returns, and enhance overall satisfaction. This proactive approach reinforces your brand’s reliability and builds long-term customer trust.

Trail Running Sock Manufacturing: What Leading Factories Prioritize

To meet evolving market demands, progressive manufacturers focus on three pillars that align with brand goals: precision craftsmanship, sustainability, and agile delivery.

- Custom Knitting Techniques: Precision for Performance

You gain consistency by using advanced knitting machines that integrate anti-slip patterns and targeted cushioning zones seamlessly. For technical designs like ribbed arch panels or breathable mesh zones, factories employ 3D knitting technology—eliminating bulky seams while ensuring durability on rocky trails.

- Sustainable Material Sourcing: Aligning with Eco-Conscious Buyers

Modern brands increasingly prioritize environmentally friendly fibers. Partner with factories offering recycled polyester (from ocean plastics) or organic merino blends. Certifications like Global Recycled Standard (GRS) add credibility to claims, particularly for buyers in regions with strict eco-regulations. This shift helps you attract retailers targeting environmentally aware trail runners.

- Rapid Production Cycles: Capturing Seasonal Demand

Speed matters in fast-moving markets. Leading suppliers streamline workflows by integrating design and production teams, slashing prototyping timelines to 3–4 weeks. With MOQ flexibility, you can test small batches before scaling, minimizing overstock risks for seasonal collections

Future-Proofing Your Line: Trail Running Sock Trends to Watch

Staying ahead in a competitive market means anticipating shifts in athlete needs. Here’s how to align your product strategy with emerging demands.

- Smart Integration: Performance Tracking Embedded in Socks

You can elevate functionality by weaving sensors into fabrics to monitor metrics like stride efficiency and muscle strain[^5]. Partner with factories using seamless knitting techniques to embed these features without compromising durability or comfort. For trail-focused products, this tech attracts data-driven athletes while reducing returns linked to underperforming gear.

- Biodegradable Materials: Pioneering Eco-Conscious Rugged Gear

Brands prioritizing sustainability gain loyalty from environmentally aware consumers. Opt for fibers like plant-based polymers or algae-derived yarns that decompose naturally after use[^5]. Factories specializing in eco-certified sourcing ensure compliance with global standards, helping you market products as both high-performance and planet-friendly.

- Climate-Ready Engineering: Heat Regulation for Extreme Terrain

Adapt designs to address temperature extremes. For hot climates, use mesh ventilation zones paired with UV-protective blends. In cold conditions, integrate thermal-regulating merino layers without adding bulk. Work with manufacturers offering regional testing to validate adaptability—ensuring your products perform in deserts, mountains, or rainforests

Conclusion

The difference between a disposable product and a performance staple lies in thoughtful design. Every element—from strategic cushioning zones that absorb impact to anti-odor treatments that keep gear fresh—shapes how athletes perceive your brand. By addressing critical pain points like blisters, foot fatigue, and premature wear, you reduce returns while fostering loyalty among trail runners who demand reliability.

As a leading manufacturer of performance-driven socks, we combine advanced knitting technology, eco-certified materials, and rapid prototyping to bring your vision to life. Contact us to get free quote.

FAQs

What sets a trail running sock apart from other running socks?

A trail running sock is engineered to handle rugged terrains with enhanced durability, extra support, and superior moisture management. These features reduce foot fatigue and improve overall performance, which can lower return rates and boost customer satisfaction.

What customization options are available for your products?

You can choose from a range of materials, colors, reinforcements, design features, and packaging. Our team works closely with you to tailor the product—from design to packaging—ensuring it fits your brand’s vision and end-customer needs.

What support do you offer during the design and development process?

You have access to our experienced team who can assist with material selection, feature integration, and performance testing. This collaboration ensures that the final product meets both market trends and the high standards of your customers.

What certifications or industry standards do you meet?

You can ask for details regarding our compliance with relevant certifications and standards. Meeting these benchmarks ensures that your product is safe, reliable, and meets market expectations.

What production capabilities does your facility offer?

We provide automatic bulk production, strict quality control, and flexible customization options. This means you can adapt the design and materials to meet specific market demands while ensuring consistent quality.