Indoor trampoline parks operate in a fast-growing, highly competitive sector where safety, guest experience, and operational efficiency directly determine profitability. Among all equipment used inside a facility, grip socks play a surprisingly strategic role—they reduce slip-related incidents, support insurance compliance, reinforce branding, and even contribute to secondary revenue.

This guide is designed for trampoline park owners, operations directors, and procurement teams who need a clear, data-driven framework for choosing the right grip socks. Rather than generic descriptions, this article focuses on specifications, compliance requirements, operational workflows, and revenue implications—the factors that matter most in B2B settings.

Industry Context: Why the Right Grip Socks Matter

Modern trampoline parks face a new set of operational realities:

- Rising insurance scrutiny and liability claims

- Competition from multi-attraction centers

- Increased customer expectations for hygiene & comfort

- Higher emphasis on branding and guest lifecycle value

In this environment, grip socks are no longer a simple accessory. They influence safety outcomes, hygiene control, brand experience, and revenue generation. Because every participant wears them, socks effectively become part of the park’s controlled safety system.

Compliance, Liability and Insurance Alignment

Trampoline parks must demonstrate that they maintain structured, consistent processes to reduce risk. Grip socks are one of the easiest ways to reinforce such controls.

Industry Standards and Alignment

While ASTM F2970 and IATP guidelines do not mandate specific sock types, both emphasize the need to prevent slip hazards and maintain safe, predictable floor conditions. Insurance carriers often seek clear, standardized footwear policies when evaluating a facility’s risk profile. A park that requires appropriate grip socks—and enforces that requirement reliably—shows proactive safety management, which strengthens its position in liability evaluations.

How Grip Socks Influence Liability Outcomes

Slip-and-fall events remain a leading cause of incident reports within trampoline facilities. When a park can demonstrate that every participant was wearing approved non-slip socks, it reduces ambiguity around guest behavior and equipment responsibility. A uniform sock policy provides operators with cleaner documentation, more predictable auditing outcomes, and better alignment with insurer expectations.

Building a Consistent Footwear Policy

A strong policy does not stop at requiring socks. It involves standardized staff procedures, clear signage, predictable customer touchpoints, and basic recordkeeping. Parks that implement a uniform process—every guest receives approved socks, employees verify compliance at checkpoints, and POS records track sock distribution—operate with much stronger legal defensibility.

Once the park establishes a compliant and enforceable footwear policy, the next step is choosing the right sock specifications that support both safety and operational efficiency.

Technical Specifications: What a Trampoline Park Sock Should Be

A grip sock designed for consumer use at home is not sufficient for commercial trampoline attractions. Parks need socks engineered for durability, grip stability, and repeat use in high-intensity environments. Below is a specification framework suitable for professional procurement.

Grip Pattern and Material Performance

The sole is the functional heart of any grip sock. Silicone-based grips provide the most reliable traction, especially when they cover most of the sole. Full-coverage grip layouts distribute friction more evenly and perform better on angled trampolines. PVC alternatives tend to wear down faster and become slippery once degraded. Parks that want to reduce incident frequency should prioritize medical-grade silicone with a high-density pattern.

Fabric Composition and Durability

A reliable blend typically includes high cotton content for comfort, polyester for structural integrity, and a small share of spandex for elasticity. This combination helps socks maintain shape after repeated washing and prevents early sagging or stretching. Optional antibacterial treatments add hygiene control, especially valuable in high-traffic parks or multi-day summer camps.

Construction Quality

High-tension seams at the toe, heel, and arch prevent tearing, which is common after extended jumping sessions. The best socks retain grip adhesion, and fabric integrity for 30 to 50 washes, making them suitable for both retail and controlled rental systems. Colorfast dyes ensure the socks maintain visual appeal despite exposure to sweat, detergent, and disinfectants.

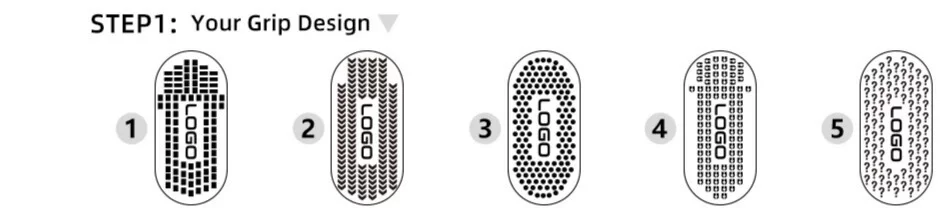

Sizing, Identification and Branding

Operational efficiency improves when socks are easy for staff to recognize and distribute. Offering three consolidated size groups—children, youth, and adults—simplifies inventory and accelerates POS interactions. Color-coded cuffs or woven size tags help employees identify sizes instantly. Branding on the instep or sole turns socks into a consistent promotional asset that visitors bring home.

These specifications ensure that the socks function not only as safety equipment but also as durable, cost-efficient assets within a high-traffic commercial environment.

The Commercial and Operational Role of Grip Socks

Beyond safety equipment, grip socks are a small but strategic revenue and experience tool.

Sales and Distribution Models

Some parks require every participant to purchase branded socks, generating strong retail margins and ensuring safety uniformity. Others include socks in the admission price to create a frictionless entry experience and reduce POS congestion. A smaller number use a rental model—issuing socks, collecting them back, and laundering them—often to support sustainability messaging or to simplify recurring guest experiences. Each model influences cost structure, staffing, inventory turnover, and customer satisfaction differently.

Revenue Contribution and Brand Building

Because every visitor interacts with socks, they become a reliable secondary revenue driver. Parks often release seasonal designs, birthday-party editions, or branded souvenirs that encourage repeat purchases. Membership programs frequently include socks in welcome kits, reinforcing value for loyal customers. In many facilities, sock sales represent a measurable portion of total retail revenue.

Operational Considerations

Operators must balance procurement cost, inventory levels, and shrinkage. Lost socks, damaged socks, or mismatched sizes can slow down front-of-house processes. A well-planned stock strategy—combined with display organization and size-banding—reduces waste and improves both customer flow and staff efficiency.

With the policy and procurement framework in place, the park must shift toward consistent day-to-day management to maintain performance standards.

Implementation and Long-Term Management

Selecting the right socks is only the beginning. A successful footwear program integrates procurement, training, stock management, and incident tracking.

A typical implementation process begins with defining the park’s safety and footwear policy, followed by supplier selection and sample testing. Once specifications are approved, operators update their point-of-sale system, signage, waiver language, and staff training materials. From there, ongoing management focuses on inventory thresholds, wear-pattern inspections, friction performance, and periodic supplier reviews.

Strong operational leadership also monitors indicators such as slip incident rates, sock sales per visitor, shrinkage, repeat usage patterns, and guest feedback on comfort or hygiene. These metrics help parks determine whether their current sock design, enforcement policy, or supplier arrangement needs adjustments.

Addressing Common Operator Challenges

Even with good specifications and policies, parks often encounter recurring issues. Visitors may hesitate to buy socks if they already own similar products, which can be resolved through first-visit incentives or membership discounts. Inventory confusion usually results from poor size-coding systems rather than actual stock shortages. Premature grip wear generally indicates insufficient silicone density or sub-standard adhesion methods. Staff enforcement gaps can be corrected through clearer signage and the introduction of dedicated checkpoint roles.

Each challenge has a predictable root cause and a straightforward operational remedy when the park’s processes are well-aligned.

FAQs

Why do trampoline parks require special grip socks?

Trampoline parks require grip socks to prevent slip-and-fall accidents, improve hygiene, and comply with insurance and safety guidelines. Regular socks lack the traction needed on trampoline surfaces, while bare feet increase abrasion and contamination risks. Non-slip grip socks deliver controlled friction, reduce liability exposure, and ensure every participant follows a standardized safety policy managed by the park.

What kind of grip socks are best for trampoline parks?

The best grip socks for trampoline parks use full-sole silicone traction, reinforced stitching, and a durable cotton–poly–spandex fabric blend. Full-coverage silicone delivers a stronger multi-directional grip than dot patterns, while reinforced seams extend lifespan. Parks should choose socks tested for friction performance, offer three consolidated sizes, and support custom branding for consistent safety and operational control.

Can guests bring their own grip socks to a trampoline park?

Guests can bring their own grip socks only if they meet the park’s safety standards, such as clean condition, closed-toe design, and having full-sole traction. Many parks still require park-branded socks to control quality, ensure consistent grip performance, and reduce liability. Clear acceptance rules at entrances and online help avoid confusion and protect operational safety.

Are regular socks safe to wear on trampolines?

No. Regular socks become slippery on trampoline surfaces and significantly increase the risk of falls. They provide almost no friction, lose stability when damp, and offer no protection against abrasion. Most parks prohibit regular socks entirely to maintain safety compliance, reduce liability, and ensure every participant uses controlled non-slip footwear.

How often should trampoline parks replace their grip socks?

Parks using rental or reusable systems should replace grip socks every 20–30 wash cycles or whenever grip patterns show visible wear, peeling, or reduced traction. For retail-only models, socks remain the guest’s property, but the park should still monitor performance feedback, inspect samples periodically, and adjust procurement if durability issues appear.

The right trampoline grip socks significantly improve safety, liability protection, operational efficiency, and profitability. For trampoline parks, they should be treated as part of the core safety infrastructure, not an optional accessory.

A well-defined specification, combined with a consistent internal policy, ensures the park meets compliance requirements and enhances guest experience at scale.

If you need custom-branded, ASTM-aligned grip socks for your trampoline park, Max Hosiery can support you with sampling, bulk production, and private labeling through our dedicated manufacturing team.