Introduction: Strategic Healthcare Textile Procurement for Specialized Populations

For healthcare suppliers and procurement professionals, diabetic socks are more than just basic hosiery—they’re a vital tool in diabetic foot care. Designed to reduce pressure, prevent ulcers, and manage moisture, these socks directly influence patient outcomes and regulatory compliance. Unlike regular socks, diabetic styles require careful evaluation of materials, construction, and certifications. This guide outlines key factors for selecting high-quality diabetic socks, from technical standards to clinical impact, helping procurement teams make informed, value-driven decisions. By treating diabetic socks as essential medical textiles, not commodities, suppliers can support better care and reduce long-term treatment risks.

Market Analysis: The Diabetic Hosiery Segment Growth Trajectory

The diabetic hosiery market is entering a phase of steady expansion, shaped by rising global diabetes rates, heightened focus on preventive care, and shifting reimbursement policies. As of recent projections, the global diabetic sock market is expected to reach $380 million by 2027, growing at a CAGR of 5.2%. This makes it one of the more resilient segments within the healthcare textile industry. For procurement professionals, understanding where this growth is happening—and why—is critical for informed stocking, vendor selection, and product positioning.

Product Category Differentiation

The diabetic sock segment is not monolithic. It includes several functionally distinct product types that target specific diabetic foot complications:

- Non-binding socks designed to improve circulation and reduce pressure around the calf and ankle.

- Moisture-wicking models that prevent fungal infections and maintain skin integrity.

- Cushioned socks with reinforced soles and padding to relieve pressure points and reduce the risk of ulcers.

- Antimicrobial-treated options to minimize bacterial exposure for high-risk patients.

Understanding these categories allows suppliers to tailor assortments to specific patient profiles, rather than offering a one-size-fits-all solution.

Evolving Distribution and Reimbursement Strategies

Distribution is expanding beyond hospitals and DME suppliers into retail pharmacies, e-commerce platforms, and hybrid direct-to-consumer models. While Medicare reimbursement remains limited, diabetic socks are increasingly included in private insurance plans, HSA-eligible products, and value-based care bundles. For suppliers, this presents both compliance requirements and opportunities to align product documentation with payer criteria.

By recognizing these trends and aligning product offerings accordingly, healthcare distributors can build more competitive, clinically relevant diabetic sock programs that balance regulatory compliance, patient care, and financial sustainability.

Clinical Requirements Driving Specialized Sock Design

For medical suppliers and procurement teams, selecting diabetic socks requires more than reviewing a product label. True diabetic socks are designed to address specific clinical challenges stemming from diabetes-related complications—particularly poor circulation, neuropathy, infection risk, and delayed wound healing. Understanding these underlying conditions helps procurement specialists distinguish between genuinely therapeutic socks and products that simply carry the “diabetic” label without clinical value.

Circulatory Needs

Many individuals with diabetes suffer from peripheral arterial disease, which restricts blood flow to the feet. Socks must avoid constriction—especially around the calf and top band—to prevent further impairing circulation. Non-binding tops and stretchable fabrics help maintain blood flow. In contrast to standard compression socks, diabetic socks are designed for minimal pressure, ensuring comfort without increasing vascular risk.

Neuropathy Protection

Diabetic neuropathy reduces sensation in the feet, increasing the risk of unnoticed injuries. Socks must have a seamless interior and cushioned soles to reduce friction, absorb shock, and prevent pressure points. Without proper padding and friction control, small wounds may go unnoticed and worsen rapidly.

Infection Control

Reduced immune response in diabetic patients makes skin infections more likely. Moisture-wicking materials like bamboo or treated cotton blends help keep feet dry, reducing the chance of fungal or bacterial growth. Some socks incorporate antimicrobial yarns to offer added protection.

Skin Integrity Support

Even minor skin irritation can escalate in diabetic patients. That’s why these socks use soft, non-abrasive fibers and gentle construction to avoid skin damage. Breathability and moisture balance are also key to keeping the foot environment stable.

By understanding these needs, medical textile buyers can make informed decisions that improve patient outcomes and meet compliance standards.

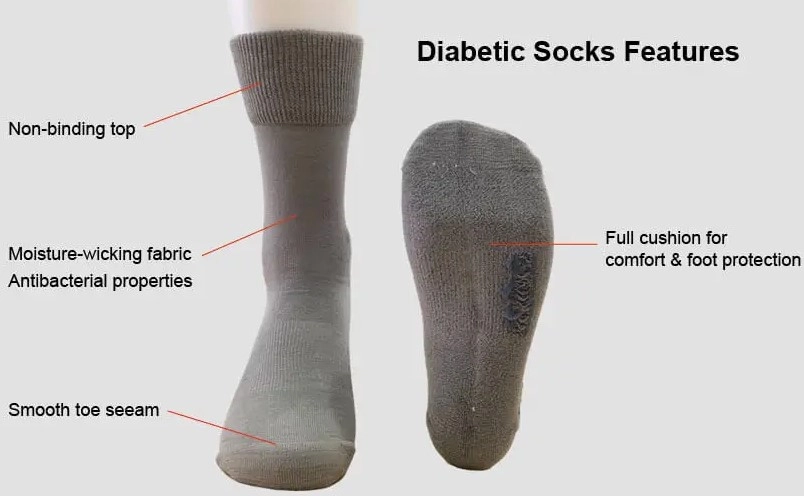

Technical Specifications That Define Diabetic Sock Performance

For healthcare suppliers and medical distributors, evaluating diabetic socks requires more than reviewing labels or marketing claims. True performance is defined by how well the socks address the specific risks faced by diabetic patients—especially poor circulation, neuropathy, and skin vulnerability. To make reliable purchasing decisions, procurement teams should focus on four core technical pillars: non-constriction, moisture control, protective padding, and material composition.

Non-Constrictive Design

A proper diabetic sock must not restrict blood flow. Look for non-binding cuffs and seam-free toes, which help prevent pressure points and irritation. Unlike compression socks, diabetic hosiery should accommodate foot swelling without reducing circulation. This design is essential for patients with peripheral vascular disease.

Moisture-Wicking and Breathability

Excess moisture can lead to skin breakdown and infections. High-quality diabetic socks use moisture-wicking yarns like bamboo, polyester blends, or specialty synthetics to keep feet dry. Additional features such as ventilation zones and antimicrobial finishes help reduce microbial growth and skin maceration, especially for patients with compromised immune function.

Targeted Cushioning for Pressure Relief

Padding in the right areas helps protect high-risk zones like the heel, ball, and toes. Advanced models may offer anatomically mapped cushioning or multi-density zones, helping redistribute pressure and absorb shock—critical for those with sensory loss due to neuropathy.

Material Matters

Blends of natural fibers (like cotton or bamboo) with synthetics offer the best of both worlds—comfort, durability, and moisture control. Some versions also incorporate copper or silver-infused fibers to resist odor and infection.

By evaluating these specifications, suppliers can select diabetic socks that not only meet regulatory expectations but genuinely improve patient outcomes.

Regulatory Compliance Considerations for Medical Textiles

Navigating the regulatory landscape of medical textiles is crucial for healthcare suppliers offering diabetic socks. Classification, labeling, quality systems, and international requirements all shape procurement, marketing, and liability considerations.

Product Classification

Diabetic socks without explicit therapeutic claims typically fall under general apparel rules. However, once you claim prevention or treatment benefits, your socks may be regulated as Class I medical devices, requiring FDA registration, quality system compliance, and product listing. In some cases, limited therapeutic claims allow for exemptions, but these must be carefully validated against local guidelines to avoid enforcement actions.

Labeling and Marketing

Your marketing language must align with classification. General wellness statements—like “supports foot health”—are usually permissible, while disease claims—such as “prevents diabetic ulcers”—trigger stricter scrutiny. Structure/function claims (e.g., “promotes circulation”) can be used when substantiated, but clear disclaimers are essential for medical device positioning. Accurate labeling ensures healthcare providers and patients receive truthful, compliant information.

Quality System Requirements

For device-classified socks, adherence to Good Manufacturing Practices (GMP) is mandatory. This includes documented quality procedures, complaint handling processes, and corrective actions to resolve production issues. Even non-device products benefit from robust quality systems to demonstrate due diligence and support supplier credibility in healthcare settings.

International Compliance Variations

Global markets impose diverse standards: the European Union’s MDR has a different risk classification approach than the U.S., Canada requires separate medical device licensing, and Asian regulations vary widely by country. Suppliers must develop market-specific compliance strategies, leveraging harmonization initiatives where possible to streamline cross-border distribution.

By understanding these regulatory dimensions, suppliers can position diabetic socks effectively—minimizing legal risk while clearly communicating product benefits. A solid compliance framework not only protects your business but also builds trust with healthcare partners and end users.

Quality Assessment Framework for Product Evaluation

In medical textile procurement, especially when sourcing diabetic socks, suppliers must move beyond surface-level marketing claims to a structured quality assessment approach. A reliable diabetic sock should demonstrate measurable benefits across four critical dimensions: clinical performance, durability, patient acceptance, and value alignment. This framework ensures that selected products contribute meaningfully to patient care and comply with procurement standards in healthcare environments.

Clinical Performance Testing

Diabetic socks must help prevent foot complications. Suppliers should prioritize socks that have undergone independent testing for:

- Graduated pressure levels that avoid restricting circulation

- Effective moisture-wicking to prevent fungal growth

- Low-friction surfaces to reduce skin shear or blisters

- Consistent pressure distribution, especially over high-risk areas like heels and metatarsals

Products backed by clinical data are more likely to align with diabetes care protocols and reduce risks of ulceration or infection.

Durability & Lifespan

Long-term value matters. High-quality socks retain shape, pressure zones, and moisture control after repeated wash cycles. Evaluating elasticity, abrasion resistance, and shrinkage helps ensure consistent performance over time—key to minimizing replacement frequency and cost.

User-Centered Design

Comfort and usability influence compliance. Look for:

- Easy-to-don construction for patients with mobility issues

- Seamless interiors to reduce irritation

- A range of sizes and neutral, wearable designs

- Positive feedback from end users, especially those with neuropathy

Value-Based Evaluation

Finally, consider total cost of ownership, not just price per unit. A sock that reduces foot injury risk and extends wear time offers better ROI. Prioritize products that balance affordability with clinical effectiveness and patient satisfaction.

By applying this structured evaluation process, medical suppliers can ensure their diabetic sock programs meet care standards, improve outcomes, and support long-term cost control.

Inventory Optimization Strategies for Specialized Healthcare Textiles

Managing inventory for diabetic socks isn’t as straightforward as it is for standard medical supplies. With variations in sizes, materials, and clinical applications, suppliers must take a strategic approach that ensures consistent availability without tying up unnecessary capital. Unlike high-turnover items, diabetic hosiery requires careful planning to match real-world demand across diverse healthcare settings.

Forecasting Demand with Precision

To avoid shortages or overstock, suppliers should rely on data-driven forecasts. Begin by analyzing the diabetic population in your market and understanding provider recommendation rates. Seasonal trends may also affect usage—such as increased purchases in colder months when foot warmth becomes critical. More advanced systems can track reordering cycles to automate replenishment based on usage history.

Aligning Stock with Patient Needs

Size distribution can make or break inventory efficiency. Stocking too many of the wrong sizes leads to waste, while gaps in popular sizes result in lost sales and dissatisfied clients. Study local demographics, and prioritize core size ranges while ensuring availability of extended options for outliers. Offering multi-size packaging or adjustable-fit options can also help reduce SKUs without sacrificing service quality.

Controlling Stock Without Compromising Care

Use reliable methods such as par-level systems and first-in-first-out (FIFO) rotation to maintain product freshness and prevent expiration. Real-time inventory tools, even simple dashboards, can provide early alerts for low-stock items and support faster decision-making.

Strengthening Vendor Partnerships

Collaborate with manufacturers to explore just-in-time delivery, vendor-managed inventory, or long-term blanket orders. These strategies reduce storage burdens while ensuring continuous product flow.

By building a responsive, well-structured inventory model for diabetic socks, suppliers can support better patient outcomes while running a lean, profitable operation.

Healthcare Provider Education: Building Clinical Value Propositions

Effective diabetic sock programs hinge on educating healthcare providers—not just about product features, but about real clinical value. Unlike standard supplies, diabetic hosiery demands an understanding of how seamless toes, non-binding tops, and moisture-wicking fabrics address specific diabetes-related foot risks. A robust education framework gives providers the knowledge to recommend the right sock for each patient, enhancing outcomes and fostering trust.

Clinical Foundations and Patient Selection

Begin by explaining diabetes pathophysiology: peripheral neuropathy, vascular compromise, and skin fragility. Illustrate how targeted sock features—like graduated compression to support blood flow or extra cushioning to reduce pressure points—directly counter these challenges. Providers should learn simple criteria for selecting candidates: poor circulation, history of foot ulcers, or recurring blisters signal strong benefits from specialized socks. Also clarify when socks aren’t appropriate, ensuring patient safety.

Translating Features into Outcomes

Show how each technical specification links to clinical benefits. For example, seamless toe closures prevent friction-induced sores, while moisture-wicking fibers reduce fungal infection risk. Demonstrating real-world case studies—such as reduced ulceration rates or faster healing times—reinforces why these design choices matter. This feature-to-benefit translation empowers providers to explain “why” as well as “what.”

Integrating Socks into Care Plans

Position diabetic socks as part of comprehensive foot care. Tie sock selection to foot assessments, patient self-care education, and ongoing monitoring. Provide protocols for follow-up, such as checking sock fit and skin condition after several weeks. This integration cements hosiery as a critical component—not an optional accessory—in diabetes management.

Delivering Practical Education

Offer concise, evidence-based materials: quick-reference guides, brief videos, and EHR-friendly resources. Host short in-service workshops or webinars, respecting clinicians’ time constraints. By aligning education with clinical workflows and focusing on real patient outcomes, suppliers can turn product awareness into genuine clinical adoption—and drive program success.

Patient Outcome Documentation for Value-Based Purchasing

In today’s healthcare landscape, value-based purchasing demands clear evidence of patient outcomes to support procurement decisions. For diabetic socks, suppliers can no longer rely solely on anecdotal claims or product features. Instead, structured documentation of clinical benefits and economic impact is essential to justify premium positioning and differentiate from commodity products. This evidence-driven approach helps transform diabetic socks into recognized therapeutic tools that contribute measurably to patient care and cost savings.

A robust outcome measurement framework tracks key indicators such as skin integrity improvements, patient comfort, and compliance rates. Comparing complication frequencies, like ulcer incidence, against baseline data or alternative interventions provides concrete evidence of clinical effectiveness. Additionally, evaluating quality of life changes through patient-reported outcomes strengthens the case for these specialized textiles.

Economic impact analysis complements clinical data by estimating savings from reduced adverse events, avoided hospitalizations, and improved patient productivity. Presenting diabetic socks as investments in total care cost reduction aligns with the priorities of value-based healthcare systems focused on long-term outcomes rather than upfront expenses.

Integrating outcome documentation into existing healthcare workflows increases feasibility. Compatibility with electronic health records, mobile patient feedback tools, automated data analysis, and standardized reporting templates streamline collection and communication of results. Effective outcome communication tailored to providers, payers, and patients ensures findings influence purchasing decisions and coverage policies.

By implementing comprehensive patient outcome documentation, suppliers can move beyond marketing claims to demonstrate tangible value, supporting wider clinical adoption and reinforcing diabetic socks as essential medical devices that improve care while enhancing business performance.

Pricing Strategy Development in the Medical Textile Market

In today’s healthcare landscape, value drives purchasing decisions more than ever. For diabetic socks, pricing strategies must balance profit margins, competitive positioning, and perceived clinical value while considering reimbursement policies. Moving beyond simple cost-plus pricing, suppliers need comprehensive frameworks that reflect the economic realities of healthcare providers and patients, ensuring sustainable business performance and market relevance.

Communicating Value Beyond Price

Effective pricing is closely linked to clear communication of benefits. Suppliers should focus on outcome-based messaging that ties product use to reduced complications and cost savings. Demonstrating comparative advantages over generic alternatives and emphasizing the sock’s quality, durability, and longevity helps justify premium pricing. These elements shift the conversation from cost alone to total value, resonating with decision-makers seeking long-term savings.

Tailored Pricing for Diverse Channels

Different market segments require distinct pricing models. Institutional healthcare facilities often prefer volume-based pricing, while pharmacies and retail channels demand margin flexibility. Direct-to-patient sales must consider affordability and non-reimbursement, and insurance-aligned models require compliance with coverage limitations. Adapting pricing to each channel enhances market penetration and reduces friction.

Aligning with Reimbursement and Competitive Positioning

Navigating reimbursement is critical—pricing should reflect coverage policies, supported by clear documentation and coding resources. Additionally, analyzing competitor pricing helps position products within the quality-price spectrum, ensuring alignment with brand values and market expectations. Understanding price sensitivity allows suppliers to optimize pricing without undermining perceived value.

By developing sophisticated, segmented pricing strategies combined with strong value communication, healthcare suppliers can build diabetic sock programs that are both financially sustainable and competitive in value-conscious markets.

Competitive Differentiation Through Specialized Product Knowledge

In today’s crowded healthcare market, diabetic sock programs must go beyond basic features or price competition to achieve meaningful differentiation. Suppliers who focus on clinical evidence, healthcare provider education, patient support, and quality assurance can build strong competitive advantages that improve both market position and patient outcomes. This strategic approach transforms diabetic socks from simple commodities into valuable healthcare solutions that support long-term care and supplier growth.

Building Credibility with Clinical Evidence

One of the most effective ways to stand out is by backing product claims with solid clinical evidence. Conducting and sponsoring outcome studies, collecting real-world case reports, and compiling comprehensive literature reviews provide proof of effectiveness. Additionally, ongoing clinical testing ensures the product performs consistently in patient settings. This rigorous evidence base builds trust among healthcare providers and sets a supplier apart from competitors relying on unverified claims.

Strengthening Provider Relationships

Developing deeper, more strategic partnerships with healthcare professionals moves interactions beyond simple sales. Offering clinical education programs, engaging medical advisors for feedback, providing consultation support for diabetic sock programs, and sponsoring continuing education opportunities help position suppliers as trusted collaborators. These relationships foster loyalty and encourage providers to recommend your specialized products with confidence.

Enhancing Patient Support and Experience

Supporting patients with educational materials, compliance tools, and integration with broader diabetic care strategies creates added value beyond the product itself. Mechanisms to gather patient feedback also enable continuous improvement. By focusing on patient-centric programs, suppliers differentiate their offerings through superior service and outcomes.

Ensuring Quality Through Documentation

Transparent quality assurance is essential in medical textiles. Establishing standardized testing protocols, securing third-party certifications, implementing quality management systems, and openly sharing testing results reinforce product reliability. This commitment to verifiable quality helps healthcare buyers make informed, evidence-based purchasing decisions.

By embracing these multifaceted strategies, diabetic sock suppliers can transform basic medical products into distinct, trusted solutions that deliver lasting value for both healthcare providers and patients while achieving sustainable business success.

Conclusion: Implementing a Comprehensive Diabetic Sock Program

To successfully launch and sustain a diabetic sock program, partnering with an experienced manufacturer is key. Max Hosiery provides tailored solutions combining clinically validated products, comprehensive provider education, and expert operational support. Our deep industry knowledge ensures your program meets clinical standards, regulatory demands, and market expectations while driving business growth. Whether you’re developing new offerings or refining existing programs, we can help you deliver superior patient outcomes and stand out in competitive healthcare markets. Reach out to Max Hosiery’s medical textile specialists at [email protected] today. Let us support your journey toward building effective, evidence-based diabetic sock programs that benefit both your patients and your business.

FAQ: Key Considerations for Diabetic Sock Programs

Why do diabetic patients require specialized socks different from regular hosiery?

Because diabetes can cause poor circulation, nerve damage, and slower healing, diabetic socks are made to reduce pressure, prevent skin irritation, and keep feet dry. Regular socks may cause injury or infection due to seams, tight cuffs, or poor moisture control.

What technical specifications define genuine diabetic socks versus regular hosiery?

Real diabetic socks have non-binding tops, seamless toes, moisture-wicking fabrics, and added cushioning. These features help reduce pressure, protect sensitive skin, and support circulation—unlike regular socks, which may lack these protective elements.

How should healthcare suppliers evaluate the clinical effectiveness of diabetic socks?

Check pressure levels, moisture-wicking ability, durability, and get real user feedback. Lab tests and clinical input together offer a full picture of whether the socks truly help patients with diabetes-related foot risks.

What regulatory considerations apply to diabetic sock marketing and distribution?

If socks claim medical benefits, they may be classified as medical devices and must meet local laws, including FDA or CE regulations. Even without those claims, marketing must be honest and follow textile labeling rules.

How can suppliers effectively educate healthcare providers about appropriate diabetic sock selection?

Offer clear explanations of sock features, evidence summaries, and tools for easy clinical use. Use short guides, digital content, and occasional in-person sessions. Focus on how socks improve outcomes, not just how they’re made.