Introduction to Football Grip Socks Manufacturing

In today’s competitive sports equipment market, choosing the right manufacturer is more than a purchase—it’s a strategic partnership. Football grip socks directly affect player safety and performance, making supplier selection critical for distributors, team suppliers, and retailers. These socks require specialized manufacturing beyond typical hosiery, focusing on precise grip patterns and durability. For procurement and product teams, knowing how to evaluate manufacturers—from technical skills to reliability—can prevent costly supply chain issues. This guide walks you through proven methods to assess, qualify, and partner with football grip sock manufacturers, helping you build a strong, dependable product line that meets market demands. Whether launching a private label or sourcing custom team socks, these insights support confident, informed decisions in this specialized category.

Market Analysis of Performance Sock Demand

Market Overview and Demand Segmentation

The football equipment market continues to grow steadily, driven by rising player participation and higher performance standards. The football grip sock segment is expanding rapidly, with a projected market value of $412 million by 2026 and a compound annual growth rate of 6.8%. Demand varies by customer type: professional and elite amateur teams often buy through direct supplier partnerships, while retail consumers primarily use sporting goods stores and online platforms. Youth and recreational players are served through a mix of team dealers and general retailers.

Regional Trends and Competitive Landscape

Adoption rates differ significantly by region. Europe leads with 68-75% of players using grip socks, followed by North America at 42-48%. Emerging markets show fast growth but from a smaller base. The manufacturer landscape includes specialized grip sock producers, large football equipment firms branching into grip socks, and general hosiery companies developing technical expertise.

Pricing and Innovation Outlook

Wholesale prices in the B2B segment range from $6 to $14 per pair, depending on technology and order volume. For equipment providers, choosing manufacturers with strong R&D capabilities offers opportunities to stay ahead in innovation, ensuring product differentiation beyond basic supply.

Technical Requirements for Athletic Performance

Football grip socks must meet far higher standards than regular hosiery due to their critical role in player performance and safety. The key feature is the grip itself, usually created with silicone or similar compounds. This grip needs to maintain consistent thickness, pattern clarity, and strong adhesion through intense use and over many washes.

Biomechanical studies show the best grip designs provide lateral stability—preventing the foot from sliding side-to-side—while allowing natural forward movement during running. Achieving this balance requires advanced pattern engineering, not just repeating simple designs.

Materials used must excel in moisture management, quickly wicking sweat away from the skin to keep feet dry and comfortable. Moderate compression is applied to support the foot without restricting circulation, unlike medical-grade socks. The socks also need reinforced areas at the heel and toe to resist abrasion common in football, plus strategically placed cushioning to absorb impacts without affecting shoe fit. Seamless toe construction is essential to avoid irritation during long game sessions.

Manufacturers should validate their products through rigorous testing. This includes measuring grip friction on dry and wet surfaces, abrasion resistance simulating shoe wear, moisture transport rates, and durability after 20+ wash cycles.

Such thorough testing and design expertise separate true performance manufacturers from those simply applying basic grips on standard socks. For serious athletic use, choosing a manufacturer with proven technical capabilities is crucial to ensure product reliability and player safety.

Manufacturing Process Evaluation Framework

Evaluating a manufacturer’s production process is key to ensuring consistent quality and reliability in football grip socks. The process includes two main parts: base sock knitting and grip application. For knitting, important factors are machine gauge (finer gauges offer better fit and durability), needle configurations (supporting left/right foot designs), and production controls that maintain consistent tension and sizing.

Grip application methods differ widely. Screen printing is cost-effective but less precise and durable. Injection molding offers high precision and durability but needs advanced equipment. Heat transfer strikes a balance with moderate precision and good durability. Direct silicone injection provides the best grip integration but requires specialized machinery.

Material handling is critical too—proper yarn storage prevents moisture issues, dye lot control keeps colors consistent, and grip material preparation ensures uniform performance. Quality control integrated throughout production, including in-line inspections, signals a reliable manufacturer.

Top-tier producers may also offer specialized testing, custom documentation, and packaging for professional teams. This framework helps you identify manufacturers who deliver consistent, high-performance football grip socks, minimizing post-production issues and supporting your brand reputation.

Quality Control Systems Assessment

Evaluating a manufacturer’s quality control system is essential for ensuring consistent, high-performance football grip socks. The company’s quality philosophy reveals whether quality is a core value or just a compliance task. Look for a proactive culture focused on prevention and continuous improvement rather than reactive inspection.

Robust documentation is a must. Leading manufacturers maintain detailed specifications beyond basic measurements, comprehensive testing protocols with clear acceptance criteria, and full traceability from raw materials to finished goods.

Testing should cover standard physical properties like dimensional stability and abrasion resistance, alongside grip-specific assessments such as grip coefficient and moisture management. Advanced producers use statistical process control to monitor trends and address root causes, minimizing defects before they arise.

For global suppliers, certifications like ISO 9001 and Oeko-Tex confirm system reliability and material safety. Additionally, Western quality expectations and English proficiency within quality teams are vital for smooth communication and technical clarity.

Finally, verify manufacturer claims through references and direct questions on consistency, problem-solving, and transparency. This due diligence helps avoid variable product quality and reduces the need for costly inspections at your end.

Strong quality systems directly support brand reputation and customer satisfaction by delivering dependable football grip socks every time.

Customization Capabilities for Team Applications

Customization Expertise for Team-Specific Grip Socks

For football equipment providers, offering customized grip socks tailored to teams or leagues opens strong business opportunities. Evaluating manufacturers should include their technical design skills and creative support. Key factors include sports-specific experience, understanding functional needs beyond looks, and the ability to translate ideas into production-ready specs.

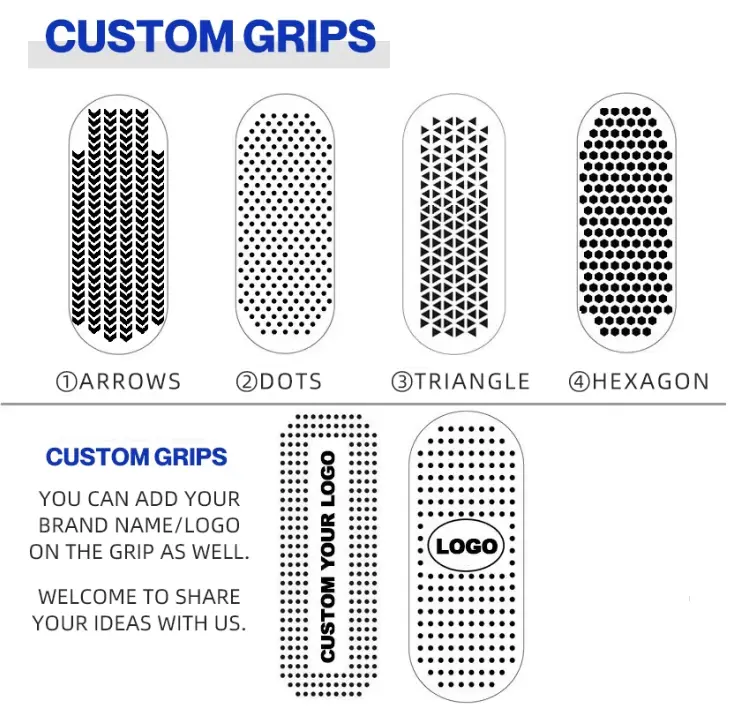

Key Customization Options

Typical options cover precise color matching—preferably Pantone—to match team colors, logo placement either integrated in grips or printed on socks, and pattern customization ranging from simple color tweaks to fully original designs. Advanced manufacturers provide digital renderings, prototypes, or virtual previews for effective development.

Flexibility and Sampling

Minimum orders vary from 300-500 pairs for basic customization to 1,000+ for fully custom designs. Manufacturers should also offer flexible reorder quantities once tooling is set. Sampling quality is crucial, with prototypes needing to accurately reflect final production, delivered reliably within agreed timelines.

Before committing, verify manufacturers’ claims by reviewing past projects and gathering client feedback. Conduct small pilot runs if possible. This ensures your partner can support unique team products, not just standard designs with team colors—key to building strong brand identity and market differentiation.

Minimum Order Requirements and Scaling Options

Order quantity flexibility plays a crucial role in managing inventory risks and supporting growth for football grip sock programs. Manufacturing partners often set minimum order requirements based on product type and customization level. Standard products usually have lower entry quantities, while custom colors or fully tailored designs require larger initial commitments. Some suppliers provide smaller reorder options after the initial production, helping brands test the market without heavy upfront inventory.

Flexible Ordering for Market Testing

For programs with uncertain or evolving demand, manufacturers offering graduated order programs can be especially valuable. These allow smaller trial runs at a higher unit cost, giving businesses room to adjust before committing to larger volumes. Understanding a supplier’s capacity to scale production alongside your program growth is equally important. Key factors to consider include maximum monthly output, current capacity utilization, and plans for future expansion.

Lead Time and Inventory Management

Lead times vary depending on materials, complexity, and order volume. Typically, sourcing raw materials can take several weeks, followed by production and quality control phases before shipping. Businesses with seasonal or irregular demand should prioritize suppliers who can offer flexible scheduling and collaborate on inventory risk solutions. Contingency plans for sudden demand changes are also critical to avoid stockouts or excess inventory.

Carefully assessing these factors ensures your grip sock supplier aligns with your business needs—balancing order size, cost, and supply reliability to support long-term success.

Supply Chain Integration Considerations

Effective supply chain integration is crucial for optimizing cost and operational efficiency in football grip sock programs. When evaluating manufacturers, consider their logistics capabilities, such as available carriers, multi-product order consolidation, and experience with destination-specific customs requirements. Packaging also matters—look for standardized master cartons, well-organized inner packaging, and balanced protection that aligns with sustainability goals.

Inventory management varies widely. Options include just-in-time production to reduce inventory costs, safety stock programs where suppliers hold inventory, blanket orders for flexible delivery, or consignment inventory at customer sites. Assessing a manufacturer’s data sharing tools is essential, including electronic data interchange (EDI), inventory visibility, and customer portals that provide real-time updates.

For companies using ERP systems, compatibility with supplier portals and data standardization can minimize manual work and errors. International suppliers should be evaluated for their import logistics experience, compliance documentation, and strategies to handle global shipping disruptions or trade policy changes. Thorough supply chain integration evaluation ensures manufacturers support smooth processes and scalable growth without adding administrative burdens.

Cost Structure Analysis Beyond Unit Price

Understanding the Full Cost Structure Beyond Unit Price

When selecting football grip sock manufacturers, focusing only on the unit price can be misleading. A full cost structure analysis reveals the total economic value each partner offers. Key cost elements include materials (40-60% of cost), direct labor (15-30%, varying by automation and location), overhead, and profit margin (usually 10-20%). Understanding these components helps make meaningful price comparisons.

Volume and Customization Impacts on Cost

Order volume heavily affects cost efficiency. Larger orders benefit from setup cost spread, better material purchasing rates, and streamlined shipping. Custom designs add development expenses like design, sampling, and tooling fees, which must be allocated across order sizes to understand true costs.

Indirect Costs and Price Stability

Beyond product costs, consider quality-related expenses such as returns and replacements, as well as inventory and administrative efficiencies gained through reliable lead times and streamlined communication. Price stability is also critical—evaluate suppliers’ raw material cost management, currency risk strategies, and transparency about potential price changes.

Making Informed Manufacturer Choices

This comprehensive cost approach ensures you compare suppliers fairly, avoiding misleading low-price offers that hide hidden costs or compromises. By analyzing total economic impact, procurement teams can select manufacturing partners that support long-term business success, not just short-term savings.

Compliance and Certification Requirements

As football grip socks expand into youth, retail, and professional markets, regulatory and certification compliance has become a core evaluation criterion when selecting manufacturers.

Material safety compliance is essential. Qualified suppliers should offer clear documentation that their materials comply with EU REACH standards, California Proposition 65, and CPSIA regulations for children's products. Look for labs conducting restricted substance testing and traceability systems linking yarns, dyes, and finished goods.

Performance-related claims—like moisture control or arch compression—must be backed by documented lab tests, especially for markets governed by truth-in-advertising laws. Suppliers should be prepared to substantiate product features with repeatable test data.

Labor certifications are also rising in importance. Programs such as WRAP, FLA, or SA8000 verify ethical manufacturing practices, particularly in regions where labor standards vary. For many brands, this is non-negotiable.

Environmental credentials add value for eco-conscious brands. Certifications like OEKO-TEX Standard 100, GOTS, and bluesign® ensure safety and sustainability throughout the production cycle.

Some clients—especially pro leagues or large distributors—may require adherence to custom testing protocols, documentation standards, or supplier audits. Suppliers must offer scalable document systems, testing schedules, and client-specific compliance packages to support smooth distribution.

In short, compliance isn’t optional. It’s a gateway to broader markets and lower legal risk. Select partners who treat it with the rigor it demands.

Long-term Partnership Development Strategies

Choosing a football grip sock manufacturer shouldn’t stop at checking current capabilities. Look deeper into their potential for long-term collaboration and innovation. Start with their product development mindset. Do they have dedicated R&D staff? Can they offer insights on materials, construction, or trends—not just follow your designs? Next, evaluate strategic alignment. Do you share similar goals, quality expectations, and growth mindsets? Operational compatibility—like decision-making styles and planning cycles—also affects partnership success. Financial stability matters too. A supplier with diverse clients and reinvestment habits is more likely to support your future plans than one chasing short-term profit. Long-term value also comes from continuous improvement. Look for manufacturers with cost reduction plans, productivity initiatives, and a willingness to share those gains. Strong partnerships need relationship structures, like assigned account teams and regular reviews. Finally, assess their conflict-handling style—do they solve problems or shift blame? Choosing a forward-looking partner often beats chasing the lowest cost. In the long run, collaboration drives better products and stronger business outcomes.

Conclusion with Supplier Selection Roadmap

Choosing the right football grip sock manufacturer can shape your product quality, speed to market, and overall brand reputation. Instead of relying on price alone, smart suppliers are assessed for their technical know-how, quality control, customization capability, and ability to grow with your business. A proven evaluation roadmap includes early screening (capabilities, MOQs, compliance), followed by sample testing and final trial orders. This reduces the risk of costly mismatches and missed timelines. Max Hosiery supports brands, teams, and distributors with industry-tested grip technology, flexible custom options, and production reliability. Whether you're sourcing for private label, team gear, or retail distribution, our team is ready to help. Contact us today to start your supplier qualification process and receive sample kits for review.

Information: Key Considerations for Football Grip Sock Manufacturing

What are the most critical quality factors to evaluate when selecting a football grip sock manufacturer?

Check grip consistency, durability over 20+ washes, sock construction (reinforced zones, flat seams), fit retention, colorfastness, and size accuracy. Lab testing is useful, but real-game field tests offer the best validation of actual performance.

How do minimum order quantities typically vary for custom football grip socks?

MOQ ranges from 300 pairs for basic color changes, 500–1,000 for logo designs, and 1,000+ for fully custom grip patterns. Some suppliers allow smaller trial runs at a higher unit cost.

What are typical lead times for football grip sock production and how can they be optimized?

Lead times range from 30–45 days for repeats to 60–90 days for new custom orders. Speed up by reserving materials, pre-approving specs, and building strong supplier relationships for priority production.

How should equipment providers verify manufacturer claims about grip performance and durability?

Use lab tests (friction, abrasion, wash cycles) plus player field testing. Compare blindly against known products and gather structured feedback over several weeks, not just single sessions.

What are the most common quality issues with football grip socks and how can they be prevented?

Typical issues include grip peeling, color fading, size variation, and seam discomfort. Prevent these with proper material choices, clear tech specs, consistent quality checks, and production audits.