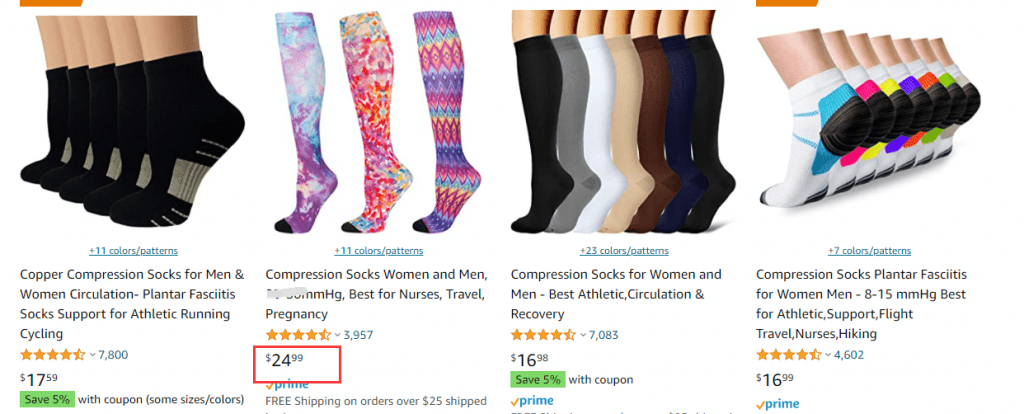

The price of compression socks on the market ranges from $2 a pair and high to $30 per pair. Despite the difference in the production and operating costs of each factory, what is the exact reason that causes such a price difference? In this article, we will reveal to you several main factors that affect the cost of compression socks from the manufacturer’s point of view. If you are a buyer for a company or are thinking of selling compression socks, this article will be very helpful to you.

The 6 main factors that make the price difference for a compression sock is material, needle, elastic specification, size, sock weight, and toe linking options.

Material

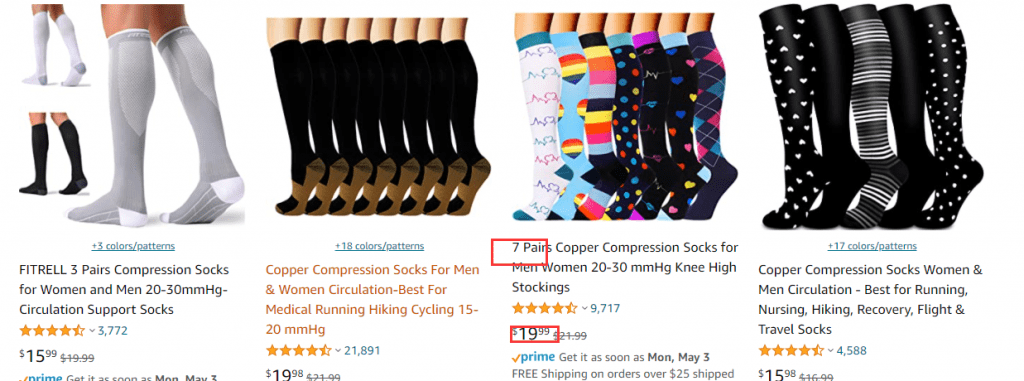

I have written an article about the raw materials used in compression socks. which describes the suitable material for compression socks. The most commonly used material is nylon, as it’s the most wear-resistant. The price of nylon is medium, and the cheaper ones will be made of polyester and polypropylene. Polypropylene is the worst raw material, which feels hard to the touch, as shown in the picture below. But it’s difficult to figure out material according to picture, so you can only compare after receiving the socks.

Generally speaking, cheap solid-color socks will be made of polypropylene, because jacquard (knitting pattern) will increase the cost. The price of nylon is similar to that of bamboo fiber and cotton, which are natural fibers and are soft and comfortable to wear. The more expensive material includes micro nylon, coolmax, wool and so on.

Price sort from high to low is: Nylon> cotton>polyester >polypropylene

And price range is from $0.5/pair to $1.4/pair based on a regular sock weight around 60 grams per pair.

Needle

We’ve also talked about needles in another article.

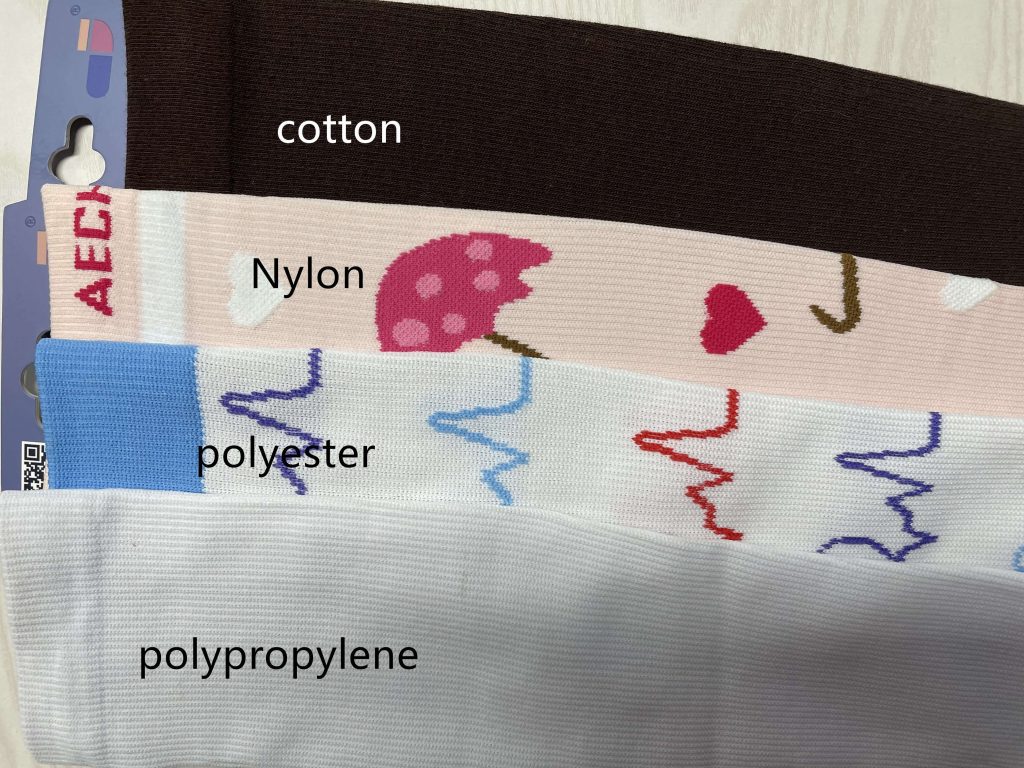

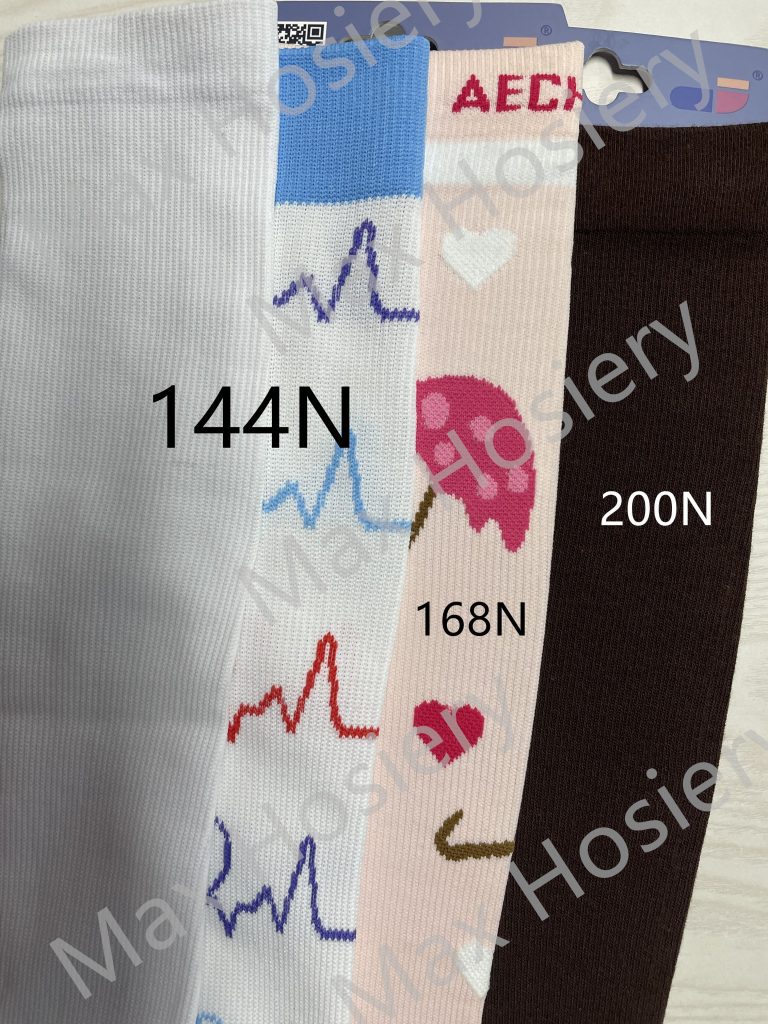

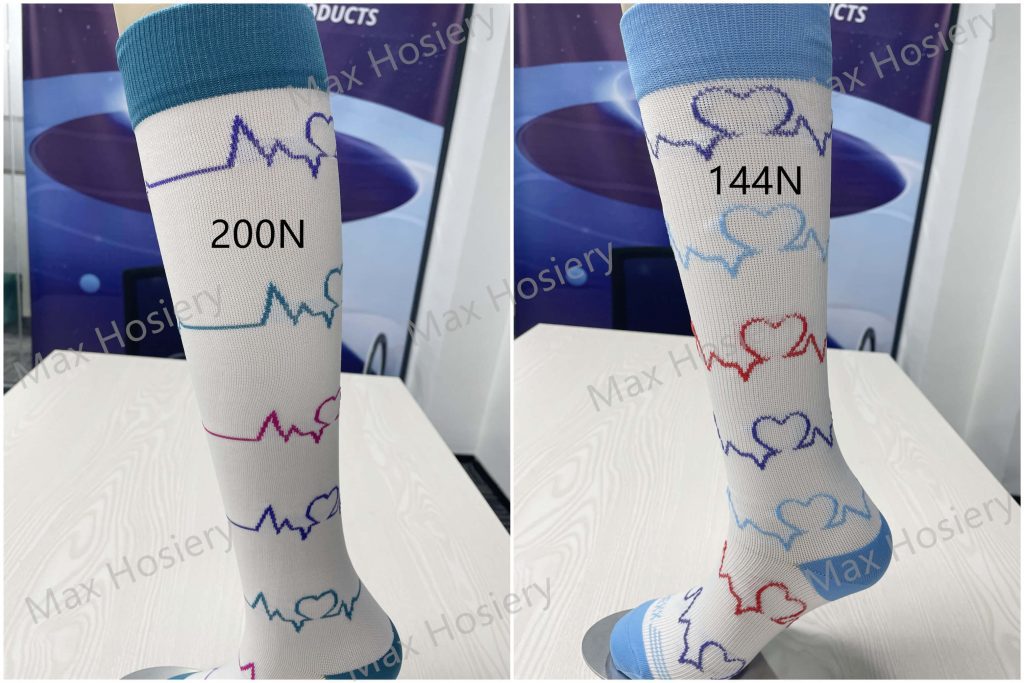

The needle of stitching is usually not a concern for the consumer but is an important factor in the price of compression socks. The common needle counts are 144n, 168n, 200n and we also have 220n/240n machines for plus sizes (can make 3XL to 8XL). The higher the needle count, the more delicate the pattern, and therefore the price is also higher. Our factory usually makes compression socks in 168 and 200n, while most of the cheaper compression socks are made in 144n. And price difference from different needles can be varied from $0.03/pair $0.15/pair.

It’s more obvious for same design socks with different needles.

Elastic

Elastic is an important factor for compression socks to maintain good compression. It’s also called spandex, elastane, elastic and so on. DuPont also has a spandex brand called Lycra, which is a man-made elastic fiber that stretches to 4-6 times its original length and quickly returns to its original length. And it can be interwoven with any other man-made or natural fibers to greatly improve the performance of the fabric.

Therefore, the main difference between Lycra and ordinary spandex is in stretching. Compression socks containing Lycra have a life expectancy of around six months to a year longer than regular spandex with consistent wear frequency. And it won’t deform the socks.

Some socks with poor spandex will be easily deformed after being pulled back or times of washing. The spandex our factory use is Lycra in case customers require to use cheaper ones.

Terry

Terry is easy to distinguish. Some socks have a terry cushion on the bottom of the foot to add bounce, or to wick away moisture. Many socks use terry as a pattern for the sock, and if you can make good use of the terry then the sock can be designed in many beautiful patterns.

Size & Weight

Sizing is something that buyers don’t usually pay attention to. Each factory may have a different size chart, but basically, they make different lengths of top tube sizes to fit the bottom of the foot. Shorter socks are lighter in weight, thus saving the cost. Therefore when looking for a quote from a supplier you should ask about gram weight. Generally speaking, a pair of evenly sized adult flat socks is around 80g a pair, and a pair with a terry foot is around 90g a pair. So the next time you are looking for a quote from a supplier you can also use the weight or a detailed size chart as a reference.

Below is a comparison between two socks in the same design and size, and you also need to know how to measure the socks size to avoid misunderstanding between you and the factory.

Toe linking

I’ve written an article about the different seams of compression sock. Here’s the link for reference. Common 3 methods are seamless toe, rosso, faked seamless toe. The difference between the three can be seen in the picture below. In terms of price, the difference is rosso toe < faked seamless toe < seamless toe. The last one is the most expensive one, and the ranking is the same in terms of comfort. So this is one of the main factors affecting the price of compression socks, and the majority is using the cheaper two options, if you want to make high-end compression socks, a seamless toe is the best choice.

Normally seamless toe socks is $0.1/pair higher than rosso toe linking for compression socks.

We Max Hosiery plan to replace all our machines with more efficient integrated machines by 2027. While maintaining the original price, we will upgrade our existing customers’ orders to hand-linked toe socks for free.

Understanding pricing factors is key, but if you’re ready to explore our various styles, customization options, and use cases for compression socks, visit our Compression Socks Collection for designs tailored to sports, medical needs, travel, and more.

Follow us here: Linkedin