In diverse working environments, the right shoes and socks are crucial in improving work comfort, safety, and productivity. Compared with daily socks, different working environments have different needs for work socks, and ordinary socks cannot meet the unique needs of some industries. For example, for workers in the logistics industry, standing and carrying heavy objects for a long time tends to wear out socks, but ordinary thin socks cannot provide sufficient protection and comfort.

At present, the demand for industrial workwear is rising in various industries worldwide, including pharmaceuticals, semiconductors, biotechnology, and chemicals. Global workwear is showing a vigorous development momentum. The global workwear market is estimated to reach US$23.5 billion by 2028, and the market growth rate is 5.7% during the forecast period. As an important market segment, the demand for work socks continues to grow.

Demand for work socks in different industries

The working environment of different industries has different demands for work socks. For example, the electronic manufacturing industry focuses on anti-static and dust-free, and the socks for construction workers emphasize wear-resistance, breathability, moisture absorption and perspiration, anti-pilling and anti-blister properties. Postal workers, who spend long hours on their feet, require socks that provide comfort, cushioning, and moisture management to reduce fatigue and improve overall foot health. Through in-depth analysis of the demand for work socks in different industries, we try our best to provide workers with a more professional and comfortable work experience by wearing work socks made by us.

Electronic Manufacturing

Electrostatic discharges are common in the electronics manufacturing industry. Electrostatic discharges can cause discomfort to workers and in some cases can even cause minor burns or pain. Static electricity can also damage sensitive electronic components and affect product quality. Electronic products are easily affected by dust, fiber and other impurities. Therefore, anti-static work socks are a necessity for workers in such working environments, which can prevent the accumulation of static electricity and improve the safety of electronic product production.

Construction

Construction workers frequently walk on rough and uneven construction sites, which can easily lead to wear and tear holes in socks. They often stand outdoors and work at high altitudes, where the environment is hot and leads to excessive sweating. In these conditions, cooling and breathable socks with antibacterial and antifungal properties can help manage moisture and reduce the risk of foot infections. Additionally, socks with padded or cushioned areas provide comfort and soothe sore feet, helping to prevent blisters and reduce fatigue during long hours of work. Best socks for construction workers often have reinforced heel and toe areas to prevent blistering, keep feet dry and comfortable, and provide maximum all-day comfort.

Mining, heavy industry, logistics industry

Mining or other heavy industries have harsh working environments with sharp rocks in the mines that tend to wear out the socks. In such environments, thermal and self-heating socks are essential to maintain warmth and comfort in cold conditions. Socks must also be lightweight yet tough, providing durable protection with no extra burden on the feet. Work socks for men or women need to be friction-resistant and more durable. In some mines, the temperature is high, so ordinary socks are easy to deform and shrink, and the ground in mines is slippery and easy to slip, posing certain safety risks. In clammy mine environments, insulation and warmth are also very important. Workers need wool work socks with good insulation, moisture-proof and anti-slip function, and reinforced heels. The best heavy-duty work socks, designed for comfort and wear resistance, can reduce fatigue and give workers a sense of ease during their long shifts. Odor-resistant and antibacterial socks help control smelly feet and maintain hygiene, while seamless designs can improve comfort. Workers in the logistics industry, especially warehouse workers and couriers, need to stand and walk for a long time every day and even carry heavy loads, so comfortable and wear-resistant work socks can reduce fatigue.

Agriculture and fishery

Agricultural and fishery workers often work in humid and hot climates outside, leading to excessive sweating and discomfort, not to mention those who have sweaty feet themselves. To combat this, breathable, antibacterial and antifungal work boot socks with cooling properties are ideal to prevent foot diseases caused by bacteria and to manage extremely stinky feet caused by long hours of wear. Socks that provide comfort and reduce fatigue are essential for those who engage in activities such as boating or heavy physical labor. Boots restrict the movement of the foot, which combined with repeated friction can cause blisters, so padded anti-blister socks are essential to reduce pain. Fishermen require thermal socks to stay warm in cold and wet conditions and waterproof socks to keep their feet dry.

Firefighting industry

The working environment of firefighters is extremely special, and they have to face a variety of extreme environments such as high temperature, high humidity and high risk. Therefore, firefighting socks should not only meet the basic wearing comfort, but also have good heat insulation performance to prevent burns. Because firefighters in the fire scene operation, feet will be exposed to high temperature environment for a long time. Socks need to be accompanied by a large amount of water frequently during firefighting operations, so socks also need to have the performance of rapid moisture absorption and perspiration and anti-fungal function to keep feet dry.

Aerospace industry

The aerospace industry has a special working environment where static electricity can cause electronic equipment to malfunction and even cause fires. Work socks are required to have strong anti-static properties. The temperature inside the spacecraft changes drastically, and the working environment may be extremely high or low temperature. Work socks are required to have good temperature resistance to adapt to the extreme working environment.

Military Industry

Frequent marching and field training can easily wear out socks and increase the risk of foot injuries. Military training often demands breathable and anti-blister socks to handle intense sweating and reduce friction-related injuries. Non-breathable socks can exacerbate this, leading to slippery feet and bacterial growth. On slippery or uneven terrain, such as during downhill movements, socks with reinforced and anti-slip performance are crucial to reduce cushioning and prevent slipping. In cold combat environments, soldiers need thermal and self-heating wool work socks to maintain warmth. Different types of soldiers (army, navy, air force, etc.) and different combat environments (wild, desert, jungle, polar, etc.) have unique functional requirements for military boot socks, such as waterproof, lightweight, cushioned, antibacterial, and antifungal properties, along with high-temperature resistance and radiation protection.

Custom work socks solutions

We are work sock factory, provide private label custom work sock solutions for your brands or online shop.

Solutions for Different Working Conditions

Performance under extreme working conditions, in-depth discussion on the performance of work socks under extreme conditions (e.g., high temperature, low temperature, humid environment, extreme physical conditions), and explains how to improve the durability and comfort of work socks in these environments through material selection and process.

- Work socks in a high-temperature environment

In a high temperature environment, socks can easily cause stuffy feet and sweating, increasing the risk of bacterial growth, and may even lead to burns. Adopt natural fibers with strong moisture absorption and perspiration, such as merino wool and bamboo fiber, which can effectively absorb moisture and sweat to keep your feet dry and cool—or high-tech synthetic fibers, such as Coolmax, which have excellent moisture-wicking and quick-drying properties. Antibacterial and anti-odor treatments should also be considered to reduce bacterial growth and prevent odors.

- Work socks for low-temperature environments

In low temperatures, such as in freezer environments, socks need to be warm to prevent frostbite on the feet. You can choose natural fibers such as wool and camel hair, which can effectively lock in the heat, or synthetic warm fibers, such as acrylic, polyester, etc., with good warmth and fluffiness. Thickened soles are also used to increase warmth and comfort; the terry lining is designed to improve the warmth effect to a certain extent.

- Working socks in a humid environment

Humidity management is crucial to preventing foot infections in humid environments. Socks made of quick-drying synthetic fibers such as nylon and polyester are ideal because they quickly absorb and expel moisture. Antibacterial and deodorant fibers such as copper, ammonia and silver can further enhance hygiene properties. Socks with mesh structure can improve breathability and accelerate moisture evaporation.

- Work socks for extreme physical conditions

In extreme physical conditions, socks may be exposed to high and low temperatures, friction and impact. Choose abrasion-resistant synthetic fibers, Kevlar, carbon fiber, etc., which are extremely strong and abrasion-resistant, as well as elastic fibers, such as spandex, which improve the sock’s elasticity and adaptability—reinforced seams for durability and cushioned terry pads to reduce foot impact.

- Socks for dark conditions

Socks made of reflective yarn can improve visibility in dark environments, effectively enhance the safety of night work, and reduce the risk of accidents. Adding reflective strips to socks can also improve visibility at night. Demand for night work socks will increase, especially in construction, logistics, security and other industries.

Optional Functional Yarn Raw Materials

In addition to the standard raw materials in the market, such as merino, cotton, nylon, polyester fiber, wool, spandex, graphene, flame retardant yarn, anti-static yarn, copper, polypropylene, TC, feather yarn, metal yarn, bamboo yarn, nylon blend yarn, etc., we also have a wide range of other functional yarn raw materials to choose from, such as anti-static, flame retardant yarn. These yarns perform excellently in some aspects compared with ordinary yarns; for example, the copper ion antibacterial rate of the work socks is up to 99%, etc.

- Merino Wool

Merino wool’s exceptional moisture-wicking properties, which outshine those of polyester and cotton, make it a top choice for outdoor sports and everyday wear. Its excellent moisture absorption, perspiration and antibacterial properties ensure a comfortable, healthy and high-performance wearing experience. Merino wool has a moisture absorption and perspiration capacity that is 35% higher than polyester fiber and 25% higher than cotton. Merino wool is a reliable high-performance option for those who pursue clothing functionality.

- Copper Yarn

Compared with ordinary socks, copper ion socks are becoming increasingly popular due to their excellent antibacterial and deodorizing properties. Their antibacterial rate is as high as 99%. Clinical trials have shown that the incidence of foot skin diseases is significantly reduced in people who wear copper-ionized socks for an extended period. Consumers also have feedback, most of which reflects that after wearing socks containing copper ions, the feet feel more refreshing and comfortable, reducing the odor.

- Graphene

Graphene has excellent electrical and thermal conductivity, mechanical strength, and flexibility. In recent years, graphene has been widely used in various fields, including the textile industry. Its good thermal conductivity can quickly dissipate heat and effectively reduce the temperature of the feet. Graphene-containing socks also have a strong inhibitory effect on common pathogenic bacteria and can reduce odor well.

- Flame Retardant Yarn

Flame retardant yarns, a special type of yarn treated for flame retardancy, are a staple in high-risk industries like firefighting and welding. Socks made of these flame-retardant yarns are stable at high temperatures. Because of their high melting point and low thermal conductivity, they can provide insulation when encountering high temperatures or open flames, greatly improving the safety of the wearer.

- Anti-static Yarn

Socks containing anti-static yarns have excellent static protection properties. They can effectively prevent static buildup and reduce the fire risk caused by static electricity. They are especially suitable for working environments prone to static electricity, such as the electronics and chemical industries.

- Reflective Yarn

Socks made of reflective yarn are an important tool for improving safety, especially for outdoor activities at night or in situations where increased visibility is required. By increasing the wearer’s visibility, these socks effectively reduce the risk of accidents, making them ideal for nighttime workers. The addition of reflective strips to the sock design also increases visibility at night. The demand for night work socks will increase especially in the construction, logistics and security industries.

Other customization options

- packaging: we will recommend different packaging according to the customer’s sales channel, such as offline brick-and-mortar stores needing to hang way packaging, retail and wholesale clients requiring specific packaging formats, Amazon merchants needing to minimize the volume and weight of the packaging with options like 2-pack, 6-pack, 12-pack or multi-pack, and super customers needing to display box packaging. In addition, we will provide you with a blank packaging mockup that fits your product size to facilitate your packaging design. For more information about sock packaging, please click here.

- Logo: We support adding a customized logo on the work socks to help you build your brand image, including OEM solutions for brand-specific requirements.

- Size and Color: They can all be customized, and we can also provide a size reference table for markets such as Europe and America.

- Length: We offer a wide selection of lengths to suit every need, including short, medium, long, over the calf, tube, knee high, and thigh-high socks.

- Design: We have regular-style work socks for your reference, including some of our highest reviewed models that have received excellent feedback from customers. Of course, we also accept customized designs with different patterns according to your specifications to provide you with a full range of customized services.

Raw Materials And Quality Assurance In The Supply Chain

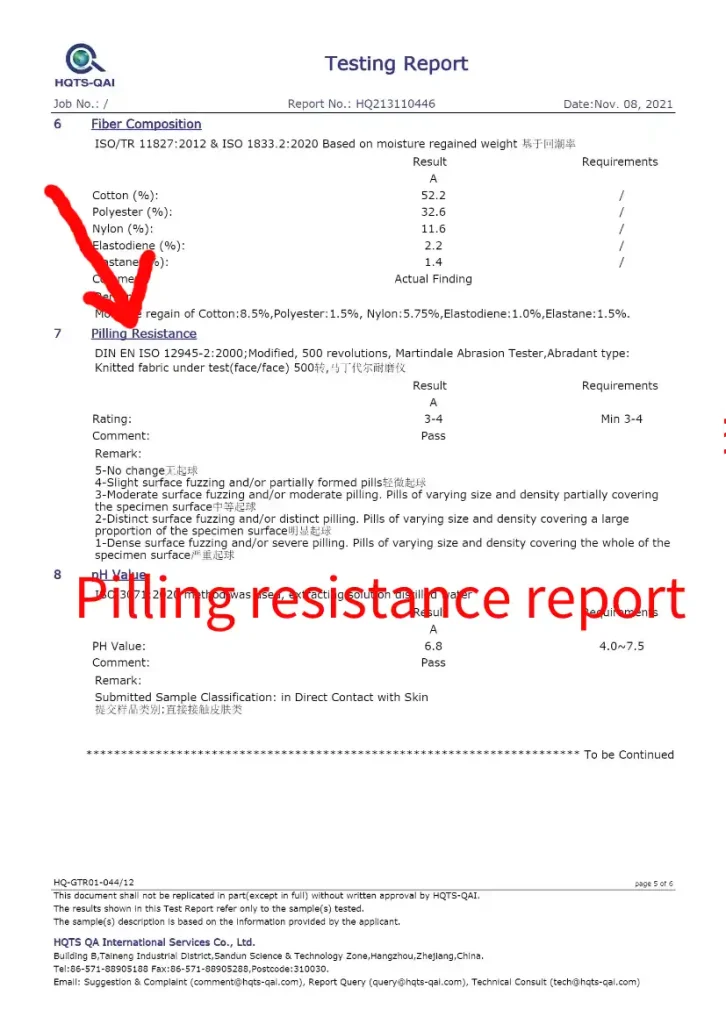

Raw material testing and content certification

Regarding raw materials, we ensure that each batch of wool socks has undergone strict content testing. You can ask to see the test report to confirm that we use high-content wool. In this way, you can rest assured in the purchasing process, your consumers are assured of the quality of your brand, and the cooperation between us is smooth.

Raw material certification and safety guarantee

Consumers have higher requirements for product safety, especially for skin-sensitive people, and at the same time, consumers are increasingly concerned about environmental issues. Most of our raw materials have passed the OEKO-TEX certification and have reached the safety standard of baby grade. This is especially important for sensitive skin consumers who can effectively avoid skin allergies and other problems. We have the relevant certificates to ensure that the products you purchase are safe and secure. In addition, we are actively exploring and applying bio-based raw materials, such as bamboo fiber and organic cotton, to meet consumers’ demand for environmentally friendly products.

Product quality testing and certification

We know that consumers have high requirements for product durability, color fastness and other performance indicators. The possible fading and deformation of products during use will seriously affect product quality and brand image. We have comprehensive test reports on color fastness, tensile strength and pilling resistance of socks, which we can provide to you as reference. These reports are available to you, which can help you further verify our products’ durability and quality stability in your purchasing decisions.

QC Production Inspection

Socks are on the opposite side when they come off the knitting machine, and our workers will inspect the socks for defects while turning them over; socks are set on metal molds during the molding process; at this time, workers will also be asked to inspect the appearance and quality of the socks, and we have set up a particular problematic product exhibition area to display defective socks, it will be used to guide workers to eliminate socks with substandard quality.

During the packing stage, our workers will carefully match each sock. It sounds troublesome, but to ensure that each sock can be paired successfully with the correct size and design. This is an essential procedure. And before the shipment, we will conduct quality inspections on the bulk according to AQL standards to further ensure product quality.

In addition, for Amazon seller customers, barcodes are critical in inventory management. We have a scanning process of each shipment’s barcode to our final quality control procedure to ensure that the socks are accurately identified when they arrive at the warehouse, significantly reducing the risk of logistical errors.

Click here for a YouTube video of sock production at the factory.

Conclusion

Choose MaxHosiery to customize work socks for your brand, you can receive durable, high-quality products. Contact us for getting a free quote or discuss your custom work sock requirements and thoughts.

Contact information: Email: [email protected]

FAQ

Why Wear Work Socks?

For ordinary socks, consumers are mainly concerned with comfort, while for work socks, users not only emphasize comfort, but also safety. In different working environments, the functional attributes of work socks are emphasized. In addition to ensuring comfort during long working hours, work socks can also provide additional safety for workers in specific environments.

What are the Benefits of Work Socks?

Men’s work socks not only have the basic performance of moisture absorption and perspiration, but also must have specific protective functions. For example, work socks in the electronics manufacturing industry need to have anti-static function; work socks in the construction industry emphasize wear resistance and moisture wicking performance; and work socks for logistics workers are not only required to be wear-resistant, but may also have reflective function to improve the safety of night work.

How to Choose the Best Work Socks?

Ensure that the socks you choose provide optimum comfort and functionality, depending on the work environment and individual needs. When choosing work socks, the following basic factors need to be considered: comfort, abrasion resistance, moisture wicking, odor resistance and temperature regulation.

Is Cotton or Polyester Better for Work Socks?

It depends on the needs of the working environment and the preferences of the consumers. If consumers want comfort and breathability, cotton work socks are a better choice. But if they want durable and quick-drying socks, polyester is a good choice.