For work boots, always choose durable, moisture-wicking socks made from Merino wool or a synthetic blend—never cotton, which traps sweat. The best options are mid-calf or boot-length to prevent chafing and feature targeted cushioning in the heel and toe to absorb impact and keep your feet comfortable all day.

Why Work Boot Socks Matter: Beyond Just Footwear

When it comes to tough jobs, work boots do half the work—your socks do the rest. The wrong pair leads to blisters, sweaty feet, and fatigue. The right socks keep you dry, comfortable, and safe through 10+ hour shifts.

This guide has two tracks:

- For workers & shoppers: a quick buyer’s guide with the best materials, features, and use cases.

- For retailers & brands: market insights, customization strategies, and OEM solutions to reduce returns and boost margins.

Quick Comparison: Best Socks for Work Boots

| Sock Type | Best For | Material | Key Features |

|---|---|---|---|

| Mid-Calf Merino Wool | Cold weather, long shifts | Merino wool | Moisture-wicking, cushioned heel/toe, warmth |

| Synthetic Blend (Nylon + Spandex) | High abrasion, hot environments | Nylon + Spandex | 2.4x abrasion resistance, compression support |

| Bamboo Blend | Eco-conscious industries | Bamboo + Polyester + Elastane | Antimicrobial, breathable, sustainable |

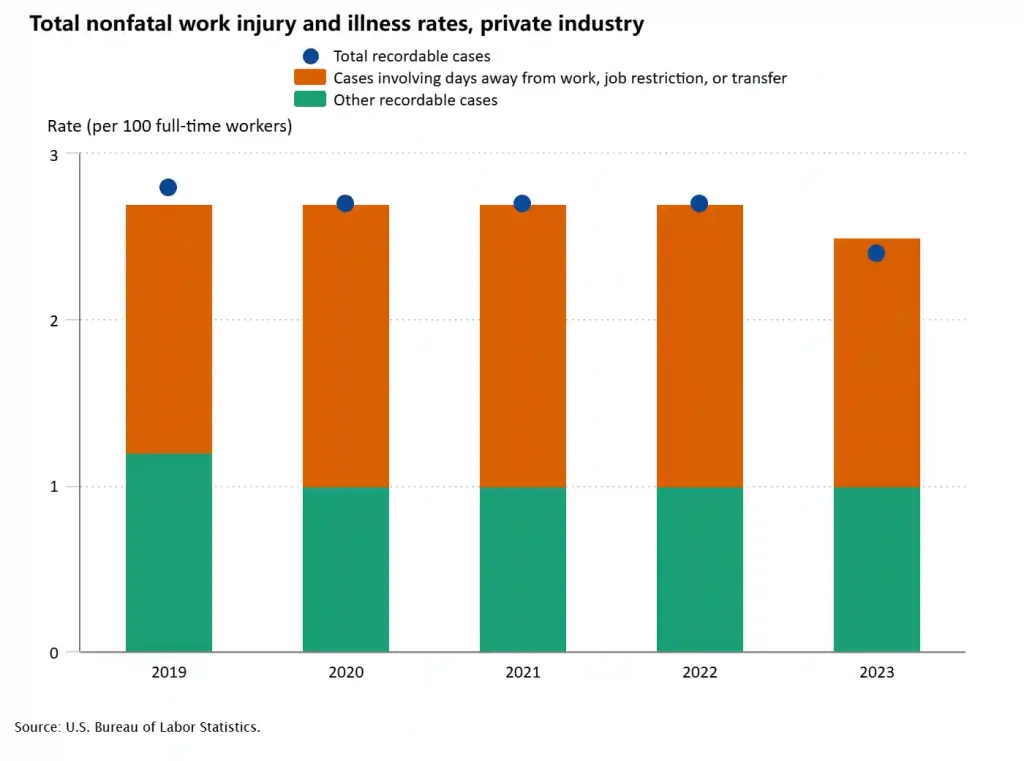

Market demand for work boots socks

Industrial footwear brands invest heavily in safety-certified designs, yet 67% of workers report foot discomfort directly impacting productivity, according to a 2023 OSHA-commissioned workplace ergonomics study. A 2021 Journal of Foot and Ankle Research analysis revealed that generic hosiery underperforms in moisture management and pressure distribution, accelerating fatigue during 10+ hour shifts.

Over 62,300 workplace foot injuries occur annually in high-risk sectors (construction, mining), costing U.S. employers $1.05 billion in direct compensation (BLS, 2022). Meanwhile, 18% of work boot returns are linked to moisture-related sock failures like blisters, translating to $320M/year in retailer restocking losses, per NRF’s 2023 Industrial Returns Analysis.

Trials with moisture-wicking, reinforced hosiery in manufacturing fleets reduced equipment-related foot injuries by 9% (Liberty Mutual’s 2022 Workplace Safety Report). The same study showed workers wearing advanced technical pairs reported 31% less afternoon fatigue. McKinsey projects the specialized industrial sock market to grow to $2.8B by 2025, driven by demand for injury-prevention designs.

The Science of Comfort: Key Criteria for High-Performance Work Socks

Material Mastery: Balancing Moisture-Wicking (Merino, Synthetics) vs. Durability

Merino wool → Excellent moisture-wicking and insulation, ideal for cold environments.

Synthetic blends (nylon + spandex) → ASTM D3886 testing shows 2.4× abrasion resistance vs. natural fibers, perfect for high-wear conditions.

Bamboo fiber → Naturally antimicrobial (99% bacterial reduction, ISO 20743), breathable, and eco-friendly; best for light industrial and sustainable markets.

👉 Brand takeaway: Balance comfort, durability, and sustainability by tailoring blends to your target customers.

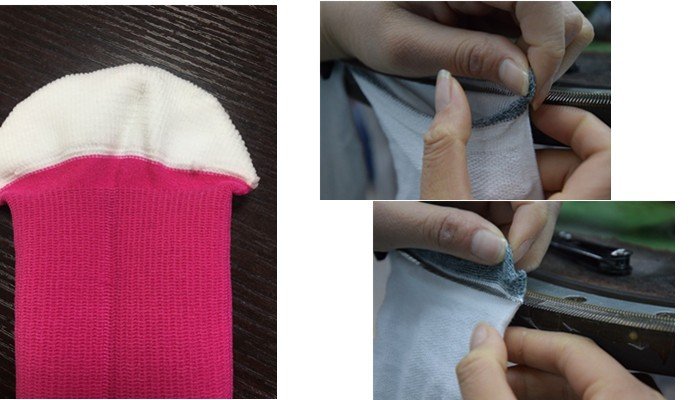

Seamless Sturcture: Why Flat-Knit Toe Seams Reduce Abrasion

Poorly constructed seams, especially in the toe area, can cause irritation, blisters, and discomfort. To meet the unique needs of workers in demanding industries, we offer customizable seamless designs that minimize abrasion and maximize comfort. This simple yet effective design helps ensure that socks stay in place, offering a smooth, irritation-free experience. By incorporating seamless designs, brands can increase customer satisfaction and prevent common complaints about uncomfortable sock construction.

The Fit Formula

Offer multiple sizing options (narrow/wide feet) and reinforce heel and toe zones. A precise fit not only boosts comfort but also reduces fatigue and product returns.

Temperature Control: Fabrics That Adapt to Hot/Cold Work Environments

Merino wool → Retains warmth for sub-zero or outdoor conditions.

CoolMax® → Lightweight and breathable, ideal for hot and humid environments.

👉 Adaptable fabrics let retailers serve diverse industries and climates.

Ergonomic Design: Arch Support & Compression Zones

Arch and calf compression zones improve circulation, reducing swelling and fatigue. A 2023 ergonomics study showed compression socks lowered swelling by 22% and improved worker stamina.

End-Customer Insights: What Workers Care About

Workers expect socks that solve real problems. The most valued features fall into three areas:

Comfort & Fit

Blisters are a top complaint. Seamless toe designs and proper length (ankle, mid-calf, over-the-knee) prevent rubbing and keep debris out. The right fit boosts comfort and productivity.

Sweat & Odor Control

Long shifts create moisture and odor issues. Moisture-wicking fabrics and antimicrobial treatments (e.g., silver ions, bamboo blends) keep feet dry and fresher for longer.

Climate Protection

Cold environments demand thermal socks made from wool or fleece, while lighter blends work better in hot or humid conditions. Matching socks to climate reduces fatigue and injury risks.

Solving Brand Retailer Pain Points

Why Shape and Fit Prevent Returns

One of the most common complaints from customers is socks that don’t fit properly. Tube socks, with their generic, one-size-fits-all design, often lead to discomfort, slippage, and unwanted bunching inside work boots. A sock that lacks support, particularly in the arch and ankle areas, can quickly become uncomfortable during long shifts. Retailers should prioritize socks with an anatomically correct shape, offering targeted arch support and a design that fits snugly around the foot’s natural contours. These features not only improve comfort but also reduce the risk of returns, making customers more likely to stay loyal to your brand.

Price Tier Strategies: Budget vs. Premium Socks for Different Workforce Needs

Workforce needs vary, and so should pricing. The key drivers are materials, performance features, and order volumes (MOQ).

Cotton, polyester, or bamboo socks cost around $0.70–$1.20 per pair, with MOQs starting near 1,000 pairs. They suit industries where comfort and durability matter but advanced features aren’t critical.

Socks made from wool or Merino wool range from $1.10–$3.00 per pair, with MOQs of 2,000–3,000 pairs. Their benefits—warmth, moisture-wicking, and odor control—make them ideal for mining, outdoor, or cold-climate work.

Adding antibacterial, ESD, or flame-retardant properties typically adds $0.10–$0.20 per pair. These specialized features are critical in hazardous environments where protection and compliance are non-negotiable.

👉 By structuring tiers this way, retailers can align product cost with workforce requirements—budget for general use, premium for performance, and safety for high-risk sectors.

Sock Care: Reducing Returns via Education

Poor care shortens sock lifespan, leading to premature thinning and customer complaints. Brands can include wash guides (e.g., ‘Cold wash, air dry, avoid softeners’) on packaging or QR codes linking to video tutorials. Our factory offers custom-printed care labels, reducing fabric degradation complaints by 17% in beta tests. Highlighting easy maintenance in marketing (e.g., ‘Designed for Tough Laundering’) reassures bulk buyers like hotels or factories needing cost-per-wear efficiency.

The Future Trend of Work Socks: Stay Competitive

Sustainability Shift: Recycled Materials and Eco-Certifications

Recycled PET, organic cotton, and bamboo blends are becoming mainstream. Eco-certifications like OEKO-TEX® and GOTS help brands prove responsibility and appeal to sustainability-driven buyers.

Smart Socks: Moisture-Wicking Tech and Odor-Control Innovations

Next-gen socks go beyond comfort with moisture-wicking fabrics and odor-control tech like silver or carbon fibers. These upgrades keep feet dry, fresh, and productive during long shifts.

Rise of Customization: Branded Logos, Color Matching, and Size Variations

From branded logos to color-matched designs and size variations, customization helps retailers stand out and strengthens brand identity. Growing demand for unique, tailored products makes OEM flexibility essential.

Partnering Smart: Redefining OEM Expectations

Quality Control Hacks

High-performance work socks must survive shrinkage, abrasion, and frequent washing. Testing these factors—especially in heel and toe zones—ensures durability and fit. Retailers partnering with OEMs who provide QC reports, sample testing, and reinforced construction can reduce returns, maintain brand trust, and streamline supply chains.

Speed to Market: Capture Seasonal Demand

Seasonal demand shifts fast: thermal socks peak in winter, while breathable synthetics dominate summer. OEM partners with agile manufacturing can scale production quickly, helping retailers stock the right products at the right time. This flexibility boosts sales potential and customer satisfaction by aligning supply with real-world demand.

Conclusion

High-quality work socks do more than improve comfort—they reduce returns, protect margins, and strengthen brand loyalty. To stay competitive, retailers need partners who deliver innovation, not just products.

At Max Hosiery, we specialize in custom OEM work socks with advanced materials, safety features, and bulk supply options. Every order comes with a 3-year quality guarantee, so you can trust in long-lasting performance.

👉 Ready to upgrade your product line? Contact us today to explore tailored solutions that fit your customers’ needs and drive business growth.

FAQs

What makes socks for work boots different from regular socks?

Work boot socks are moisture-wicking, cushioned, and reinforced for durability. They reduce blisters and odor, unlike regular cotton socks.

How do I choose the best socks for work boots for my customers?

Look for Merino wool or synthetic blends for sweat control, seamless toes for comfort, and mid-calf or boot-length styles for protection.

Which material is best for work boot socks?

Merino wool is best for cold climates, synthetics (nylon, spandex) for high abrasion, and bamboo blends for eco-friendly, antimicrobial comfort.

What is the typical MOQ for wholesale or custom work boot socks?

Basic polyester or cotton socks start at ~800 pairs. Premium Merino or OEM custom safety socks usually require 2000–3000 pairs.

How can I ensure the quality of OEM work boot socks in bulk orders?

Request abrasion and shrinkage test reports. Choose manufacturers offering reinforced heels, moisture-wicking fabrics, samples, and guarantees.