Seamless socks—also called no seam socks, socks with no seams or socks without toe seams—use a flat, almost invisible toe join instead of a bulky ridge. They aren’t mandatory for every wearer, but they’re highly recommended for sensitive feet, diabetes, kids and performance sports, where even a small seam can cause irritation.

Why People Search for “Seamless Socks” and “No Seam Socks”

When people type seamless socks, no seam socks, socks with no seams or no toe seam socks into Google, they are usually trying to solve one problem: toe seams that rub. Traditional socks have a ridge of stitching across the toes; for some customers this is only a mild annoyance, but for others it means daily discomfort, morning battles with kids, or even medical risk.

Retailers and brands also search these terms when they notice recurring complaints about “annoying seams” in reviews and want to upgrade their product line without jumping blindly into higher costs. For them, understanding what “seamless socks” really means—and which construction to choose—is the key to matching comfort expectations with realistic margins.

What Is a Toe Seam in Socks?

How Regular Toe Seams Are Made

Most socks are knitted as a tube and then closed at the toe in a separate step. The toe opening is aligned and stitched together by machine, leaving a visible seam line across the toes.

This machine-linked seam is fast and cheap, which is why it dominates mass-market socks. But that extra layer of thread sits right where toes bend inside the shoe, creating a small but noticeable pressure ridge for some wearers.

Problems with Bulky Toe Seams

For people with robust feet, a regular seam is tolerable. For others, the raised ridge becomes a friction point that can lead to redness, blisters and general irritation during long shifts, long walks or sport.

Medical and sensory-sensitive groups—such as people with diabetes, neuropathy, arthritis or autism—are especially vulnerable because even light pressure or repetitive rubbing can damage the skin or trigger strong sensory discomfort.

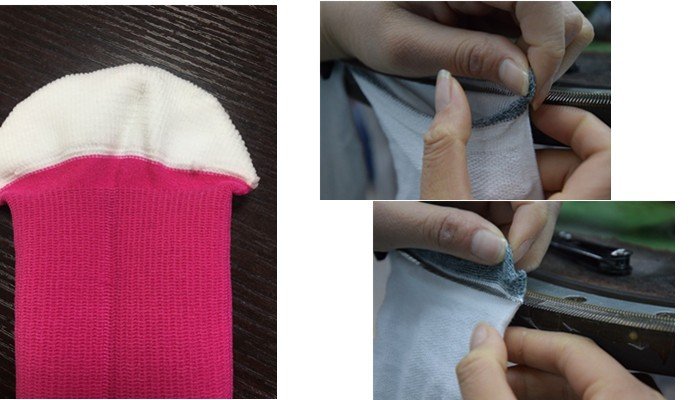

What Is a Hand-Linked Toe?

A hand-linked toe (often advertised as hand-linked seamless toe) is a higher-end way to close the sock. Instead of folding the toe and stitching a thick ridge, a worker or semi-automatic machine lines up every loop of the toe with every loop of the body and links them one by one.

The result is a very flat, smooth join that feels almost like it was knitted in one piece. Many premium and medical brands describe these as seamless socks or smooth-toe socks because the join barely presses on the toes.

Compared with a regular seam, hand-linked toes take more time and skill. That adds cost per pair, but it also delivers a clear, feel-able difference that customers quickly notice once they try them.

Types of Toe Construction: From Regular to “Fake Seamless”

In manufacturing, “seamless socks” can mean different things. For B2B buyers, it’s essential to distinguish three common constructions.There’re 3 different methods to seam the toe.

Regular Machine-Linked Toe

- Toe is folded and stitched by machine in one pass.

- Visible ridge inside the toe box.

- Lowest cost, highest output, suitable for price-sensitive everyday lines.

Hand-Linked Seamless Toe

- Toe and sock body are joined loop-to-loop.

- Join is flat and smooth; many consumers cannot feel any ridge.

- Typical of dress socks, diabetic socks, premium sports socks where comfort is a selling point

“Mock Seamless” or “Fake Seamless” Toe

- The toe is still closed by machine, but with finer thread, heat-setting or extra trimming.

- Seam looks smaller and flatter than a standard seam, yet is not as invisible as a true hand-linked toe.

- Cost and comfort sit between regular and hand-linked—often chosen when buyers want to mention “smooth toe” but keep a tight budget.

For your product page and tech sheets, it helps to name these options clearly so customers understand what level of “seamless” they are getting.

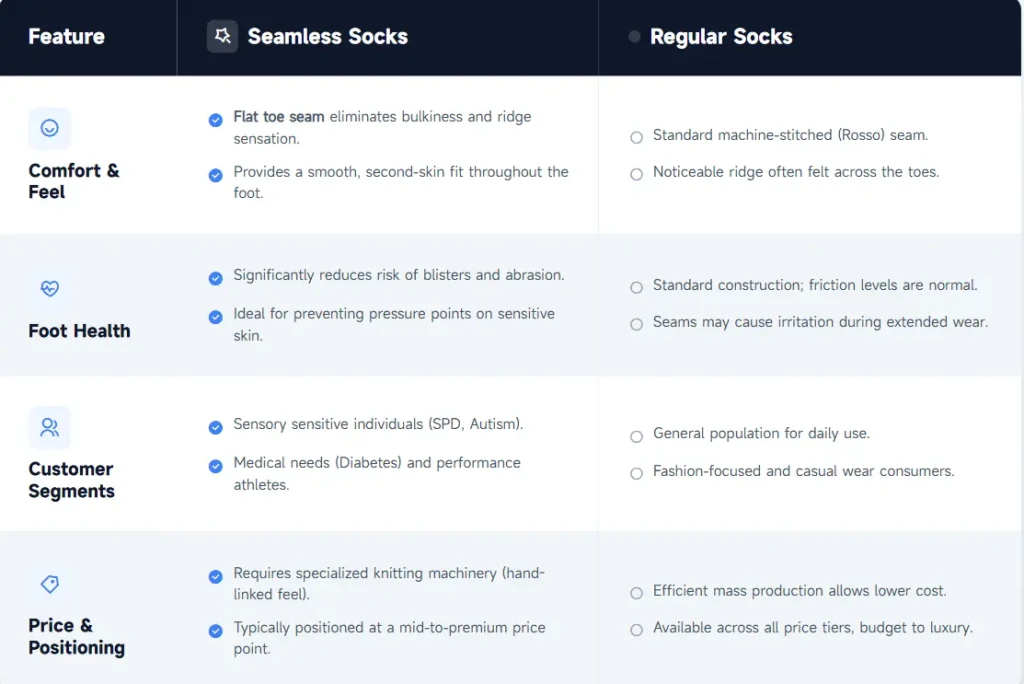

Seamless Socks vs Regular Socks: Key Differences for Your Customers

Which Socks Really Need a Seamless Toe?

Not every sock must have a seamless toe, but several groups clearly benefit from it according to medical and clinical guidance.

- Diabetic and high-risk foot patients– Doctors and guidelines frequently recommend seamless or flat-toe socks to minimize pressure and friction on fragile skin. Clinics specialising in diabetic foot care also advise patients to “look for seamless socks” to minimise irritation inside the shoe.

- People with neuropathy, arthritis or very sensitive skin – When nerves are damaged or joints are inflamed, even small pressure points can feel painful. Diabetic-sock guidelines note that seamless construction helps protect fragile skin from rubbing and breakdown, not just in diabetes but in any condition where sensation is altered.

- Kids’ and sensory socks – For children with autism or sensory processing issues, a seamless toe can be the difference between daily meltdowns and smooth mornings.

- Performance sports and long-duration wear– Sports podiatrists who design anti-blister socks highlight seamless toes as one of the key elements for preventing friction and blisters during running, hiking and other high-impact activities.

- Premium dress and everyday comfort lines– Luxury and “affordable luxury” sock brands still use hand-linked or similarly flat toes in their premium collections to remove the bulky ridge at the front of the foot, positioning this as a visible upgrade in comfort and craftsmanship.

For low-priced promotional or give-away socks, a regular seam may still be appropriate, but it’s worth offering at least one seamless option in every key category.

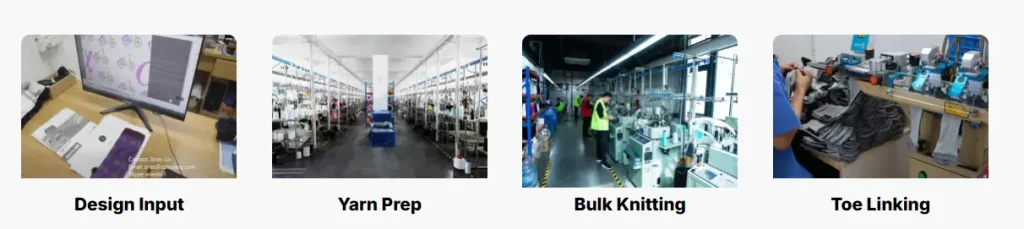

How We Produce Hand-Linked-Effect Seamless Toe Socks at Scale

Traditional hand-linking relies heavily on skilled operators and takes longer time to produce large orders. Our all-in-one machines solve this problem.

We use a new one-piece automatic machine that combines knitting and a hand-linked-effect toe closure in a single, continuous process. Instead of moving finished tubes to a separate hand-linking line, the socks come off the machine with a very flat, smooth toe ready for boarding and finishing. This keeps the comfort close to traditional hand-linking while removing a whole production step.

For a concrete example, take a 10,000-pair order:

- Conventional route (machine knit + separate hand-linking)

- Knitting and standard finishing: roughly 20 days

- Hand-linking on a separate line: another 15–20 days

- Plus packing time at the end

- Hand-linked toes typically add around US$0.10 per pair in labour and overhead on top of the base sock cost.

- Our integrated one-piece machine

- Knitting and toe closing happen in one flow, so total production time is about 25 days before packing for the same 10,000-pair order.

- Because we avoid a dedicated manual hand-linking stage, the unit cost is lower than “standard sock + hand-link surcharge” while still delivering a flat, hand-linked-effect toe.

For buyers, this means you can offer a seamless-toe upgrade with shorter lead times and a more competitive landed cost, instead of treating hand-linked toes as a niche, slow and very expensive option.

For many wearers, the difference between a regular seam and a seamless toe is not a small detail—it’s the line between daily irritation and all-day comfort. Medical and podiatry sources now treat seamless toes as standard for diabetic and high-risk feet, sensory specialists rely on them for children who cannot tolerate seams, and sports experts use them to cut down blisters in demanding conditions.

On the manufacturing side, traditional hand-linking is still the gold standard for a perfectly flat join, but it has real implications for lead time and price. By investing in one-piece machines that recreate a hand-linked effect at scale, Max Hosiery can give brands a practical middle path: socks that feel close to truly seamless, delivered on realistic deadlines, at a cost that works for both premium and volume lines.

FAQ

What does “seamless toe” mean?

“Seamless toe” describes a sock where the toe join is knitted or hand-linked to be very flat, so it doesn’t rub against the toes like a thick stitched seam.

Why are seamless socks better for sensitive skin?

Traditional seams can create rubbing and pressure points that irritate delicate or eczema-prone skin. Seamless socks use smooth, flat construction to minimise contact and reduce inflammation risk.

What are seamless socks good for?

They’re ideal for anyone who feels toe seams, especially children, athletes and people with sensory or medical issues. By reducing friction, they help prevent blisters, redness and daily discomfort.

Are seamless socks better than regular socks with seams?

For comfort-critical uses—diabetes, autism, long shifts, sports—seamless socks clearly outperform regular seams by reducing friction and pressure. For casual wearers on a tight budget, regular seams may still be acceptable.

Are seamless socks good for everyday use?

Yes. Their smooth toe and reduced irritation make them comfortable for daily wear at work, at home and during light exercise, and they can extend the life of shoes by reducing internal abrasion.