Compression socks have become a popular product across medical, athletic, and everyday wellness markets. For B2B buyers, product developers, and technical teams, understanding how compression socks work is essential. It informs product positioning, helps evaluate manufacturing quality, guides effective collaboration with factories, and ultimately ensures that the products meet both performance expectations and regulatory standards.

This article focuses purely on the mechanics of compression socks: how they create graduated pressure, how this pressure interacts with the human circulatory system, and how thoughtful sock design achieves these effects. By grasping the science and engineering behind compression socks, brands and developers can make smarter sourcing decisions and create more credible messaging for their customers.

How Graduated Compression Socks Work and Blood Flow Mechanics

Venous Return and the Problem of Gravity

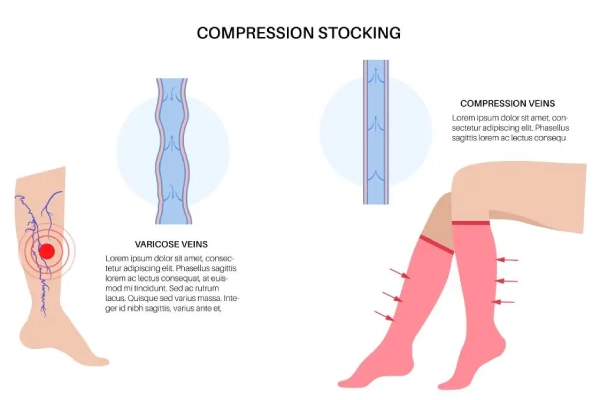

When standing or sitting for long periods, the human circulatory system faces a major challenge: blood tends to pool in the lower limbs due to gravity. The veins are responsible for returning deoxygenated blood to the heart, but this upward flow works against gravity and depends on two key natural mechanisms:

- Muscular contractions, especially from the calf muscles, act like a pump, squeezing veins to push blood upward.

- Venous valves inside the veins that prevent blood from flowing backward.

These mechanisms are effective under normal conditions but can weaken due to prolonged immobility, aging, or health issues. When this happens, venous insufficiency may occur, resulting in symptoms such as swelling (or edema), leg heaviness, pain, and increased risk of blood clots.

What Compression Socks Do in Physiological Terms

Understanding how compression socks work means recognizing their role in supporting these natural processes by applying external graduated compression pressure to the legs:

- This external pressure narrows the diameter of superficial veins, which increases the velocity of blood flow based on Poiseuille’s law.

- Graduated compression means the pressure is highest at the ankle and gradually decreases along the leg. This pressure gradient helps blood flow upward more effectively, mimicking the body’s natural circulation patterns.

- By improving venous return, compression socks reduce blood pooling and prevent stagnation, which lowers the risk of clot formation.

- Additionally, this pressure reduces leakage of fluid from capillaries into surrounding tissues, thus minimizing swelling and edema.

Key Outcomes of Proper Compression

When compression socks deliver the right level of graduated compression, wearers benefit from:

- Improved venous return, reducing strain on venous valves and the heart.

- Reduction in swelling and edema, improving comfort and mobility.

- Decreased blood pooling, which lowers leg heaviness and fatigue.

- Enhanced lymphatic drainage, supporting waste removal and inflammation control.

- Potential reduction in the risk of deep vein thrombosis (DVT), particularly in medical and therapeutic settings.

How Compression Is Engineered Into a Sock

Understanding how compression socks work also means understanding how their performance is built into the product—not added after production. The compression is engineered directly through the knitting process, yarn selection, and zoned construction.

Tension Control Through Knitting

Compression socks are manufactured using circular knitting machines, such as those produced by Lonati or similar high-precision brands. These machines are programmed to vary the tension of the yarn row by row, creating targeted graduated compression pressure across the length of the sock.

- In the ankle zone, the knitting pattern is denser, with greater yarn tension, producing the highest compression pressure.

- As the sock extends toward the calf, the tension is gradually reduced to maintain a controlled pressure gradient.

- This precise control is critical to supporting venous return and achieving consistent performance.

Yarn Elasticity and Modulus

Compression strength depends not just on knit structure, but on yarn selection—especially those with high elasticity and memory. Common materials include:

- Spandex (elastane): Core elastic fiber that delivers compression and excellent recovery

- Nylon: Provides durability, structure, and support as the main body fiber

- Polypropylene: Optional; enhances moisture-wicking and breathability

Factors like denier, ply, and twist tension influence both the compression pressure and wearer comfort. For example, higher modulus yarns will apply more force at the same tension, but may reduce stretch comfort.

Zoned Construction Logic

A well-designed compression sock strategically applies different pressure levels to specific regions:

- Ankle Zone: Delivers the highest compression (typically 20–30 mmHg for medical-grade)

- Calf Zone: Moderate compression (10–20 mmHg), maintaining the pressure gradient

- Cuff Zone: Just enough tension to prevent slipping without constricting blood flow

- Heel and Toe: Generally low-compression or compression-free zones to avoid discomfort and pressure points

- Arch or Metatarsal Bands: Optional in athletic or performance models for added foot support

Ensuring Effective Compression: Measurement and Calibration

To ensure that compression socks deliver the promised graduated compression pressure, technical validation and calibration during production are non-negotiable.

Measuring Actual Pressure (Not Estimated)

Compression level is measured in millimeters of mercury (mmHg)—the same unit used in blood pressure. Testing can be done using specialized equipment like:

- Pressure sleeves

- Medical compression analyzers

Factories that produce medical-grade or performance socks often follow standards like ISO 13485 or RAL GZ 387, which define the pressure range and tolerances for specific compression classes.

Consistency Across Production Runs

Maintaining reliable compression is a manufacturing challenge:

- Yarn properties vary with temperature, humidity, and batch conditions

- Advanced factories use real-time tension sensors to dynamically adjust machine parameters

- Post-knitting, socks go through tension calibration, heat setting, and final pressure verification

Common Challenges

- Compression drift after repeated washes due to fiber fatigue or elastic breakdown

- Uneven pressure caused by inconsistencies in knitting or yarn behavior

- Deviation from labeled mmHg range, especially if testing is skipped or done improperly

Misconceptions to Correct in Product Communication

Despite their growing popularity, compression socks are still misunderstood—often even by brands selling them. Here are common misconceptions that technical teams and marketers must address:

- “Tighter means better” – Wrong. Excessive compression can restrict blood flow and cause harm.

- “Any tight sock is compression” – False. Only socks engineered with proper tension gradients and validated pressure levels qualify.

- “Same pressure throughout the sock is ideal” – Incorrect. Without graduated compression, there is no physiological support for venous return.

- “All compression socks are medical-grade” – Not true. Many are classified as wellness or athletic socks and may lack clinical validation.

Why Deep Understanding Leads to Better Product Outcomes

Ultimately, understanding how compression socks work at a mechanical and physiological level leads to better decision-making for brands, retailers, and developers. It enables clearer and more accurate product specifications, improves communication with manufacturing partners, and strengthens customer education through sales and marketing.

Compression is not just a label—it’s a technical performance feature that depends on precision engineering. Brands serious about functionality should work closely with experienced sock factories that understand compression on both a structural and material level.

If you are developing a compression sock line and need a partner who speaks the language of yarn tension, circular knitting, and mmHg calibration, we are ready to help. Let’s discuss how we can bring your design to life accurately and at scale.

FAQs: Common Questions About How Compression Socks Actually Work

Is tighter compression always better?

No. Excessive pressure can restrict blood flow instead of supporting it. Compression must be graduated and fall within the right mmHg range for the intended user group (e.g., 15–20 mmHg for everyday wear, 20–30 mmHg for moderate medical needs).

How is the pressure level controlled in manufacturing?

It’s controlled during knitting. Machines adjust yarn tension and stitch density across sock zones. Pressure isn’t “added later” — it’s built into the structure using elastic yarns (e.g., Spandex) and machine calibration.

Can regular tight socks achieve the same effect as compression socks?

No. Regular socks may feel tight but don’t apply pressure gradually or evenly. Compression socks follow medical or performance design standards that are tested to deliver mmHg pressure curves.

Do compression socks lose their effectiveness over time?

Yes. Elastic yarns degrade with repeated washing, especially without proper care. High-quality socks retain function for 4–6 months with regular use. Brands should include wear-cycle expectations in packaging or product info.

What’s the difference between medical-grade and wellness compression socks?

Medical-grade socks are pressure-tested, certified (e.g., RAL, CE, FDA), and often used post-surgery or for vein disease. Wellness compression socks use the same pressure principles but without certification, targeting athletes, travelers, or office workers.