Who this is for: hikers, cyclists, commuters, industrial users—and Muslim readers evaluating whether “waterproof socks” can also serve as Wudu socks. In minutes, you’ll learn how three-layer socks keep water out, how merino and bamboo linings affect comfort, where failures actually occur (seams and cuff), and when a waterproof sock qualifies for masah (wiping) in Wudu.

Quick answer: how waterproof socks actually work

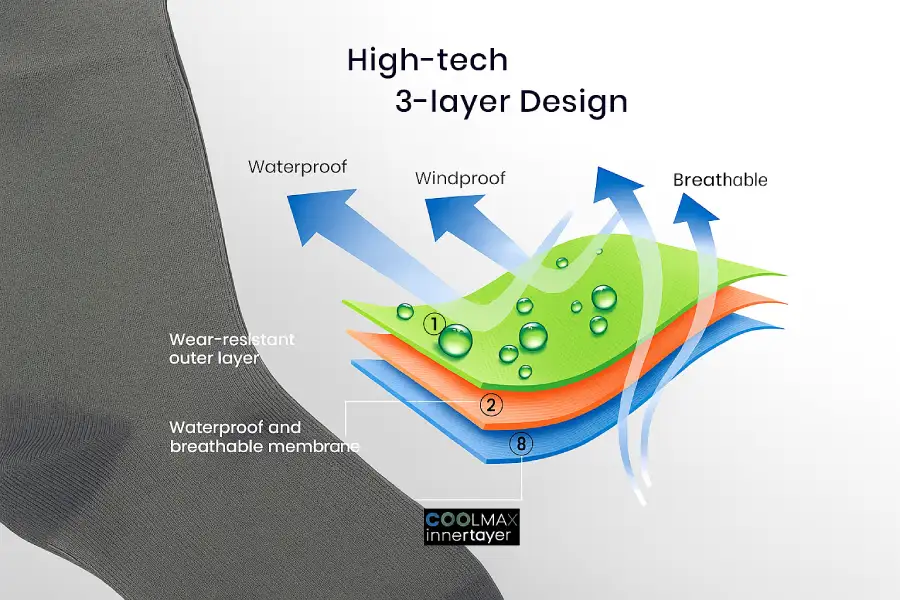

Modern waterproof socks are a three-layer sandwich: a durable outer knit for abrasion, a waterproof/breathable membrane (typically hydrophilic PU or ePTFE-type) that blocks liquid water yet passes sweat vapor, and a soft inner lining (often merino wool or bamboo viscose) for comfort and moisture management. Sealskinz popularized and documented this membrane-between-knits construction.

The 3-layer sandwich, deconstructed

Outer knit: nylon/poly for abrasion and shape retention

The outer tube takes the beating—friction against shoe linings, toe boxes, and pedals. Brands typically use dense nylon or polyester blends with elastane for recovery, so the sock stays fitted and doesn’t bag out after wet cycles. Leading manufacturers describe exactly this: a tough outer knit bonded to a waterproof core and comfort lining, rather than a single thick fabric.

What this means for buyers: prioritize models that mention reinforced heel/toe zones and durable denier yarns. That’s where most premature wear happens, long before membranes puncture.

Middle membrane: hydrophilic vs. ePTFE (and why breathability claims differ)

The middle layer is the star. Hydrophilic membranes transport moisture by molecular diffusion (they don’t have pores to clog), while ePTFE membranes rely on micro-pores. In both cases, liquid water is blocked; vapor can pass—up to a point. As outdoor tech guides explain, breathability is finite and measured differently from “waterproofness,” which is often rated with hydrostatic head (HH) tests. Higher breathability membranes usually cost more to make.

Translation for real use: in cool–cold conditions, hydrophilic socks feel comfortably dry. In hot, high-sweat scenarios, any waterproof sock can feel warm because vapor transport lags sweat production. That’s normal physics, not a defect.

Inner lining: merino vs. bamboo viscose

- Merino wool brings natural thermo-regulation and odour resistance, making it ideal for shoulder season and winter.

- Bamboo viscose (a regenerated cellulose fiber) feels silky-soft against skin, wicks well, and often comes in at a lower price point than high-merino blends.

Both are widely paired with waterproof membranes in market-leading products and category explainers. Pick merino-lined models for cold or stop-and-go days; choose bamboo-lined for mild temps or if you’re price-sensitive but still want a soft, quick-dry interior.

Seam engineering: where waterproofing wins—or fails

Waterproof socks are built as laminated tubes. The hydrophilic membrane is present throughout the sock up to the stitching located at the cuff (you can see this when turning the sock inside-out). That’s also where the waterproof guarantee ends; the brand is explicit about this boundary.

Cuff ingress & “Hydrostop.” Many “leaks” aren’t membrane failures at all—they’re top-down ingress as water runs off the leg into the opening. Some models add an internal band (often branded Hydrostop) to reduce drip-in at the cuff. It does not create a watertight seal, and full submersion above the cuff stitching isn’t recommended. Know the design limit.

Lab & spec markers worth knowing

Hydrostatic Head (HH): a lab measure (mm of water) of fabric waterproofness; outdoor gear guides explain the test (a column of water over fabric until leakage). Finished socks rarely publish an HH because seams, knit, and cuff height complicate a single figure—but membrane and apparel sources help you calibrate expectations.

Durability: real-world failure modes, and how to choose for longevity

What actually wears out first?

- Heel/toe abrasion: Sand, grit, and hard shoe counters thin the outer knit; once the knit abrades through, the membrane is exposed to scuffs and pinholes.

- Flex-point stress: Repeated bending at the ball of the foot can induce micro-cracks or delamination in low-quality laminations.

- Cuff stitching: Not a failure of the membrane—just the natural termination point where water can enter from above if submerged.

Brands with long category tenure emphasize reinforced zones and proven lamination stacks. Reviewers likewise call out models with extra measures at the cuff (e.g., Hydrostop) and sturdy outers as more durable, albeit sometimes a bit firmer in hand than cushy non-waterproof socks.

How to stack the odds in your favor:

- Choose reinforced heel/toe and a denser outer knit if you’re in abrasive environments.

- For wet commutes or stream crossings, prefer mid-calf heights with cuff features that reduce top-down ingress. Independent testers explicitly note this benefit on technical models.

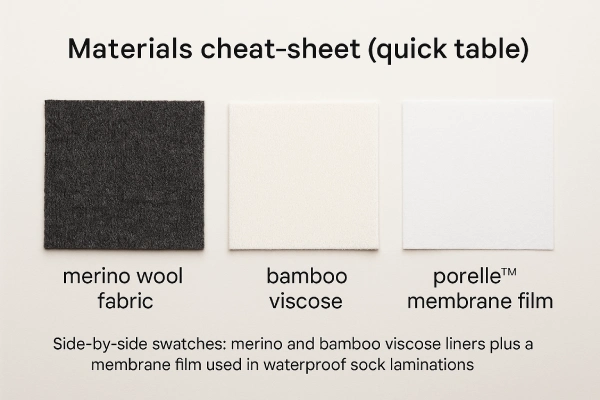

Materials cheat-sheet (quick table you can scan)

| Layer | Common materials | Why it matters | Typical issues | Seen on |

|---|---|---|---|---|

| Outer knit | Nylon / polyester + elastane | Abrasion resistance, colourfastness, shape retention | Heel/toe wear; pilling under grit | Category leaders’ 3-layer socks |

| Membrane (core) | Hydrophilic PU or ePTFE-type | Blocks liquid water; transports vapor | Breathability limits in heat; potential pinholes if outer fails | Sealskinz & other 3-layer builds; Porelle supplies membranes for laminated footwear fabrics |

| Inner lining | Merino wool | Thermal comfort; odour resistance | Price; may feel warm in summer | Cold to mixed seasons |

| Inner lining | Bamboo viscose | Soft handfeel; wicking; value | Odour control depends on blend; can feel cool when wet | Mild temps, value-priced waterproof socks |

Sources that document the three-layer construction, the hydrophilic membrane role, and the membrane suppliers: Sealskinz technical pages and Porelle documentation.

Waterproof socks vs. Wudu socks: same tech, different requirements

Technically, many “Wudu socks” are waterproof socks that also meet fiqh criteria for masah (wiping). Authoritative guides summarize common conditions for non-leather, wipe-eligible socks in the Hanafi school: sufficient thickness/sturdiness; impermeable to wiping water; coverage above the ankle; able to walk a meaningful distance in them; and being worn after completing Wudu, with standard time windows for residents and travelers. Cross-school summaries and fatwa collections discuss the principles in broader detail.

Practical implication: a regular waterproof sock can often serve as a Wudu sock if it covers the ankle, truly prevents water from reaching the skin when wiped, stays on without constant tying, and is put on in a state of full Wudu—otherwise it doesn’t qualify.

FAQs

Are waterproof socks really breathable?

Yes—up to the limits of the membrane and conditions. Hydrophilic membranes move moisture by diffusion; ePTFE-type membranes vent vapor through micro-pores. In hot, high-sweat scenarios, any laminate can feel warm.

Why don’t brands publish a simple “waterproof rating” for socks?

Waterproofness is classically measured by hydrostatic head (HH) at the fabric level. Finished socks also depend on seams, knit density, and cuff height, so a single HH figure can mislead; use HH to understand membranes, then apply construction context.

Merino vs. bamboo—what should I pick?

Pick merino for thermal regulation and odor control in cooler conditions; pick bamboo viscose for a softer handfeel and better value in mild weather. Both are common linings in three-layer socks.

Can I use my waterproof socks as Wudu socks?

Often yes—if they cover the ankle, are impermeable when wiped, are worn after completing Wudu, and are free of major holes; many summaries also note standard wiping windows for residents vs. travelers. Verify according to your madhhab.

Why do socks sometimes “leak” at the top?

Usually, this is cuff ingress—water running down the leg into the opening—rather than membrane failure. Brands guarantee waterproofing up to the cuff stitching; Hydrostop can reduce ingress, but is not a watertight seal.

Conclusion

Reliable waterproof socks follow one rule: a three-layer build—durable outer knit, a waterproof/breathable membrane, and a soft lining—keeps liquid out while venting sweat. Comfort then comes from the choice of lining (merino for cold weather and odor control; bamboo/viscose for mild weather). Edge performance is largely determined by cuff/seam design: most models are waterproof up to the cuff stitching, allowing for effective top-down ingress management. For Wudu use, pick an ankle-covering, truly impermeable sock and observe standard wiping time windows (resident/traveler).

For a fast shortlist, request a sample (24-hour reply) to validate fit, cuff ingress, and Wudu eligibility, or get an OEM/wholesale quote with MOQ & DDP.