Grip Socks Factory Tour: See How They're Built

How Grip Socks Are Built From Yarn to Final Product

Curious about what makes grip socks perform so well? At Hangzhou Zhongzhi Industry Co., Ltd., our Jiaxing Max Hosiery Co., Ltd. factory combines advanced machinery and skilled craftsmanship to deliver high‑traction, durable grip socks for brands and retailers. With over a decade of industry expertise, we transform raw yarn into finished grip socks that meet strict quality standards and client specifications.

Why Our Grip Socks Production Stands Out

Precision Knitting for Consistency: State‑of‑the‑art knitting machines produce uniform fabrics, ensuring each sock delivers the right balance of stretch and support.

Expert Grip Application Techniques: Our technicians apply non‑slip materials—silicone, PVC, or eco‑friendly blends—using controlled processes that guarantee even coverage and lasting adhesion.

Streamlined Workflow for Fast Turnaround: From machine unloading to packaging, automated lines and manual inspections work in harmony to maintain a smooth 25–30 day lead time and uphold an MOQ of 500 pairs.

Rigorous Quality Checks: Backed by OEKO‑TEX® Standard 100, FDA, CE, BSCI, and ISO 9001 certifications, every batch undergoes stringent testing to ensure durability, safety, and performance.

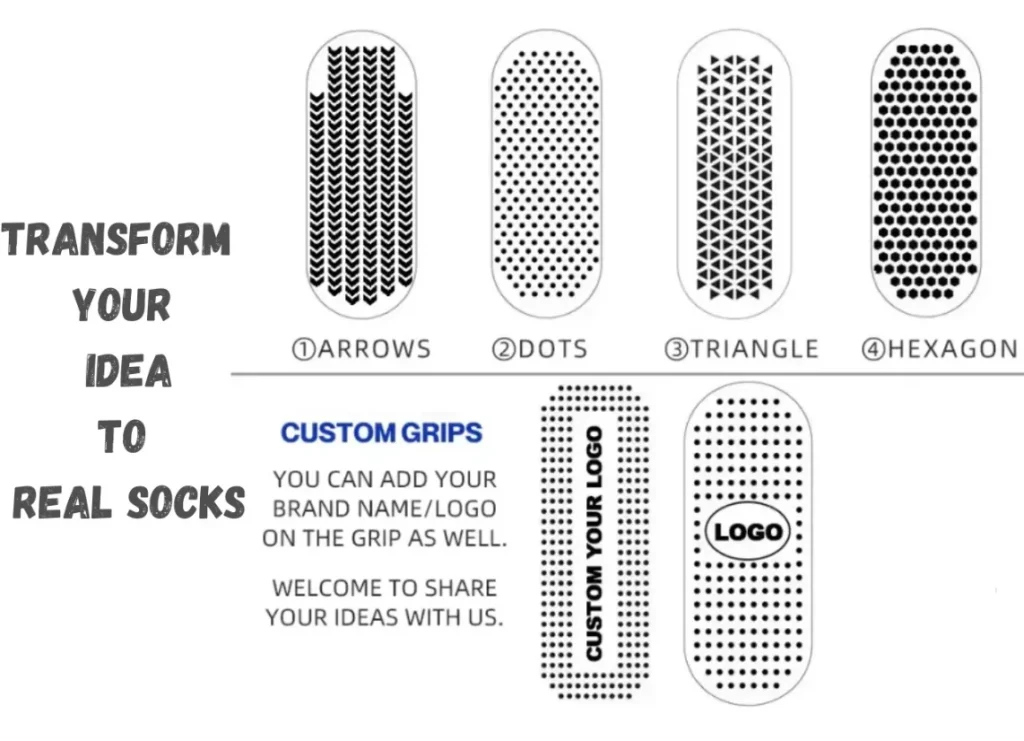

Custom Options to Match Your Brand: Choose your preferred grip pattern, material, color, and packaging design to align with your brand identity and end‑user needs.

See the engineering, precision, and care that go into every pair of grip socks. Dive into our factory tour to discover why global clients trust us for bulk orders of high‑quality, performance‑driven grip socks.