Introduction – What Are Compression Socks?

Many people have heard of compression socks or know they help support the leg muscles. But do you really understand what compression socks are and how they work? These specially designed socks apply controlled pressure to your lower legs to improve blood flow, reduce swelling, and provide muscle support. Whether you are a brand owner, retailer, or wholesaler, knowing the full details behind compression socks will help you choose the right products and serve your customers better. In this article, we’ll explain the technical structure, benefits, and manufacturing process of compression socks to give you a complete picture.

Why Are Compression Socks So Widely Used?

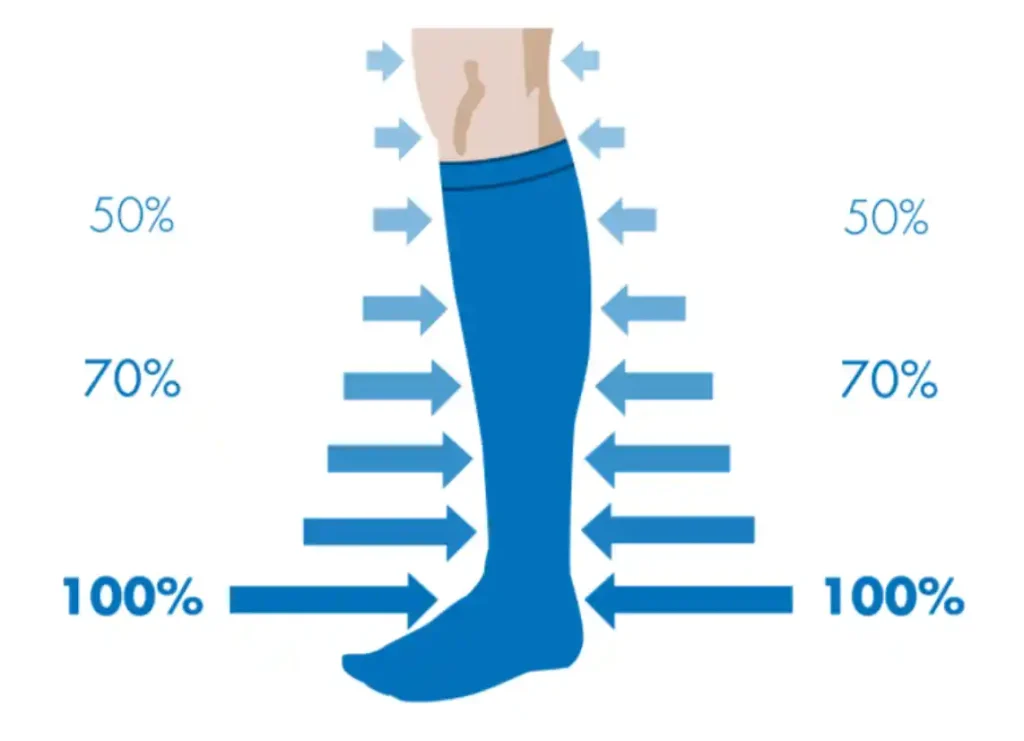

The growing popularity of compression socks lies in their versatility and science-backed function. Unlike standard socks that just cover the feet, compression socks offer targeted pressure that starts strongest at the ankle and gradually reduces as it moves up the leg.

This graduated compression helps blood circulate more efficiently back to the heart, especially in gravity-opposed areas like the lower legs. It’s an effective and non-invasive method to support vascular health, prevent fluid accumulation, and reduce fatigue.

Beyond health care, the demand is rising in sportswear, travel accessories, and even maternity apparel. From thigh-high compression socks for DVT prevention to knee-high models for long flights, the use cases are broad and still expanding.

Core Function – What Do Compression Socks Actually Do?

How Compression Works on the Legs

Compression socks are built on a simple yet powerful principle: external pressure improves internal circulation.

When standing or sitting for long periods, gravity makes it harder for blood in your legs to return to the heart. This often leads to symptoms like swelling, heaviness, or even blood pooling in the lower extremities. Compression socks apply graduated pressure—strongest at the ankle and decreasing as it moves up the leg—to help push the blood upward through the veins.

This controlled squeezing effect assists your venous return, reduces the diameter of enlarged veins, and enhances valve function inside your leg veins. It’s not just about comfort—it directly improves how your circulatory system works.

The Science Behind Pressure Zones

A high-quality pair of compression socks doesn’t squeeze your leg randomly. It’s engineered to apply precise compression levels at exact zones. For example:

- Ankle zone: highest pressure (helps push blood upward)

- Calf zone: medium pressure

- Below knee / thigh: low pressure to allow blood to continue its return path

This pressure difference is what drives better blood flow and minimizes venous pooling, especially in people who stand or sit for hours daily. That’s why support stockings for swelling are common among teachers, nurses, office workers, or anyone on their feet all day.

Support hose for leg swelling and pressure stockings for DVT are designed using this zoning principle. If the gradient is wrong—too weak or too strong—it can result in discomfort or even worsen the symptoms. That’s where factory-level expertise matters. Manufacturing compression socks requires accurate yarn tension, machine calibration, and compression testing.

This pressure system can also help with:

- Fatigue relief for athletes and workers

- Recovery after surgery

- Performance improvement in sports by reducing muscle vibration

- Swelling control during pregnancy

Compression Sock Categories

Compression socks are not one-size-fits-all. For brands and retailers planning to develop or stock compression socks, understanding the classification system is key. Differences in length, pressure level, toe design, and target user groups all play a role in functionality, comfort, and market positioning.

Let’s break them down in detail:

By Compression Level – Mild, Moderate, and Firm

Compression levels are typically measured in millimeters of mercury (mmHg), the same unit used for blood pressure. This indicates how much pressure the sock applies to the leg.

- Mild (8–15 mmHg): Ideal for light fatigue, sitting at a desk, or short flights. Mostly for general wellness.

- Moderate (15–20 mmHg): Often used for mild varicose veins or early pregnancy swelling. These are popular among retail customers.

- Firm (20–30 mmHg): This level is more medical-grade, useful for edema, post-surgery recovery, DVT prevention, and long-haul travel. It’s one of the most in-demand categories in B2B procurement.

By Length – Ankle, Knee-High, and Thigh-High

The length of a compression sock isn’t just for fashion—it directly impacts how much of the leg receives compression.

- Ankle compression socks only target the foot and lower ankle area. They’re ideal for running or diabetic relief.

- Knee-high compression socks are the most common for circulation support and travel. They fit most leg types and work for standing jobs.

- Thigh-high compression socks cover the leg up to the upper thigh, offering extended circulation control and often used in post-surgical settings or for serious vein issues.

Retailers often underestimate the need for varied lengths. Some consumers feel restricted by long socks and prefer ankle support only. Others need full-length options due to physician prescriptions.

For private label brands, offering multiple lengths within the same design line gives more control over shelf assortment and buyer preference.

By Design – Open Toe, Closed Toe, and Toeless

Toe design also affects comfort and functionality:

- Open toe compression socks are better for people with toe swelling or sensitive skin. They’re often recommended post-surgery or during hot weather.

- Closed toe compression socks resemble regular socks and are suitable for everyday use.

- Toeless compression socks are useful in clinical environments where toe inspection is required.

Toeless models also appeal to people with large feet or conditions like bunions. But this design needs stronger elasticity in the arch and heel to prevent slippage since the toe portion provides no resistance.

By User Type – Men, Women, Plus Size, and Pregnancy

Different users have different sizing and anatomical needs.

- Men’s compression socks often need wider calves and longer footbeds.

- Plus size compression socks address the needs of larger calves or edema-prone legs. They must provide flexibility without losing compression.

- Compression socks for pregnancy support both circulation and swelling during each trimester, especially in hot or humid seasons.

Some users may even prefer diabetic compression socks, which apply light pressure and avoid binding at the top band. For brands targeting these niche markets, accurate sizing and flexible elastic zones are crucial to avoid product returns. Factories should provide clear size charts and test reports to ensure fit accuracy, especially in wide calf or plus-size models.

What Materials Are Used in Compression Socks?

When it comes to compression socks, the comfort, elasticity, breathability, and durability of a compression sock are all determined by its yarn composition and knitting technique. For factories and brand buyers, choosing the right materials can affect both performance and return rates. Let’s look into the commonly used materials and their impact on product quality.

Main Fabric Choices in Compression Socks

Most compression socks are made from a blend of synthetic and elastic fibers. Here’s what they typically include:

- Nylon (Polyamide): Lightweight, smooth, and durable. Nylon forms the base of many compression socks due to its high tensile strength and ability to maintain pressure zones without tearing.

- Spandex (Elastane / Lycra): The key elastic fiber. It allows the sock to stretch and recover, essential for maintaining compression over time.

- Polyester: Less common but sometimes used in performance blends. It adds wrinkle resistance and can enhance moisture-wicking when treated.

- Cotton: Rare in true compression socks because it absorbs moisture and lacks stretch retention. However, some brands blend a small percentage for added softness.

- Coolmax® / Thermolite® / Outlast®: Performance fibers that regulate temperature and wick sweat, used in athletic or travel socks.

How Fabric Affects Compression Strength

Material density, yarn tension, and knitting technology all influence how effectively a sock delivers graduated compression. For example:

- A sock with more spandex content will have better elasticity but may require reinforced knitting to prevent over-stretching.

- Thicker yarns create more supportive fabrics, suitable for plus size compression socks or 20-30 mmHg medical-grade models.

- Light, breathable knits work well for pregnancy compression socks, where skin sensitivity and temperature regulation are important.

Some brands opt for double-layer knitting for added support zones around the arch, heel, or shin. Others add padded heels or toe pockets for comfort—though this must not interfere with pressure balance.

At the factory level, we perform compression testing using pressure measurement sleeves to ensure the final product delivers consistent gradient compression at each targeted zone.

Are Copper and Diabetic Socks Really Different?

The market offers niche versions like copper compression socks and diabetic compression socks, but how are they different?

- Copper compression socks: These include copper-infused yarns, which claim to have antimicrobial and odor-resistant properties. While some studies suggest benefits, the copper content is usually low. The performance still relies more on the sock’s pressure structure than the yarn content itself.

- Diabetic compression socks: These aren’t always true compression socks. Most diabetic socks are non-binding, lightly padded, and focus on circulation without tightness. Some diabetic compression models offer very light (8–15 mmHg) support.

Sustainable and Natural Options

More brands today are exploring natural or sustainable fibers such as:

- Merino wool blends: Naturally odor-resistant and breathable. Rare in compression socks but found in premium models for winter or hiking.

- Bamboo fiber: Soft, antimicrobial, and moisture-wicking, though not suitable for strong compression unless blended with synthetics.

How Compression Socks Are Made – From Yarn to Finished Product

Producing compression socks is not like making regular socks. The process requires precision knitting, high-quality yarns, and pressure calibration. Brands and retailers entering the compression sock market need to understand this process to better plan sourcing, QC (quality control), and packaging. Here’s how professional factories manufacture medical and performance-grade compression socks.

Step 1: Yarn Selection and Preparation

Every pair starts with selecting the right yarns. The goal is to create a fabric with controlled elasticity, long-lasting strength, and comfort.

- Nylon (main body)

- Spandex (elastic zones)

- Additional fibers for temperature, moisture, or comfort properties

Before knitting begins, the yarns are spooled, tension-tested, and arranged according to pressure zones (ankle zone yarn has tighter tension settings than calf yarn).

Different materials are prepared for ankle compression socks, plus size compression socks, and toeless models to accommodate variations in stretch and structure.

Step 2: Circular Knitting on Compression Sock Machines

Compression socks are made using specialized circular knitting machines with multi-layer tension controls. This is where the real magic happens.

- Computer-controlled machines are programmed with pressure profiles (e.g., 20–30 mmHg)

- Each part of the sock (toe, heel, arch, calf, cuff) has different tension settings

- Stitch density is adjusted to match the required compression level

The machines knit the sock tube in one piece, with built-in zones for graduated compression. For styles like thigh-high compression socks or open toe socks, the settings are adjusted accordingly.

Step 3: Linking, Toe Closing, and Heat Setting

Once the sock body is knitted:

- The toe is manually or automatically closed using flat seam linking (no ridge, to avoid pressure points)

- Socks are then heat-set to lock in their compression profile. This involves steaming at specific temperatures to fix the yarn memory

For copper compression socks, the copper-infused yarn is typically used in foot zones and must be heat-treated gently to preserve properties.

Step 4: Compression Testing and Pressure Validation

Factories test each batch using a MST (Medical Stocking Tester) or pressure measurement sleeve to validate compression zones:

- Ankle zone must match the mmHg rating (e.g., 20–30 mmHg for DVT support)

- Calf and cuff zones must show proper gradient reduction

- Socks are stretched over artificial legs or tension frames to verify shape and elasticity

Step 5: Finishing, Inspection, and Packaging

After QC, socks go through:

- Loose thread trimming and visual inspection

- Logo printing or embroidery (if requested)

- Labeling and sizing checks

- Flat or rolled packaging, with optional band wraps, hang tags, or zip pouches

Factories also offer custom packaging, especially for travel kits or retail shelves. For private-label compression sock brands, this is a key area to create perceived value.

For example:

- How to wear compression socks guides can be printed on packaging

- Washing instructions prevent performance loss

- Sizing charts help reduce return rates

Conclusion – Why Every Brand Should Understand Compression Socks

Compression socks are not just another hosiery category—they represent a technical product with real health implications and growing customer demand. Whether you’re a sportswear brand, pharmacy chain, or e-commerce retailer, understanding how they work is essential for positioning your products correctly and avoiding avoidable customer dissatisfaction.

For brands entering this market or looking to upgrade their current offerings, working with a reliable compression sock factory is key. At Max Hosiery, we specialize in OEM/ODM production of graduated compression socks, offering precise pressure control, private label packaging, and compliance with international testing standards. Whether your focus is medical-grade support or athleisure recovery socks, we can help you bring the right product to market.

FAQ

Q1: How to put on compression socks?

Start by turning the sock inside out to the heel, place your foot inside, and gently pull the sock up evenly over the calf. Use donning aids if needed for easier wear.

Q2: Can you wear compression socks to bed?

Generally, no. For most users, compression socks should be worn during the day and removed before sleeping. Exceptions include medical advice for post-surgery or DVT prevention.

Q3: How long should compression socks be worn?

Typically, wear them during waking hours—about 8 to 12 hours per day. Follow doctor’s instructions for medical conditions.

Q4: How tight should compression socks be?

They should feel snug but not painful. Proper sizing is crucial; the highest pressure is at the ankle, gradually decreasing upwards.

Q5: Are compression socks good for circulation?

Yes, they help improve blood flow, reduce swelling, and prevent conditions like deep vein thrombosis when worn correctly.