Introduction

When dealing with buyers or sourcing teams, they often ask what is the composition of your compression socks? Before answering this question, we need to know all the elements of compression socks.

All socks are made of one main material blended with elastic material. The common main material used for compression socks is nylon. Besides nylon material, we can also use other materials to produce compression socks, like cotton, bamboo, polyester, etc., even wool. Different materials will play different functions and cause different comfort. Regarding elastic material, it’s normally polyester spandex or nylon spandex.

Common Material

As mentioned in the previous post on compression socks, the main materials used in compression socks are cotton, bamboo, nylon, polyester, Coolmax, wool, and so on. The cotton yarn it’s also divided into different types, including combed cotton, modal cotton, Egyptian cotton, Pima cotton, etc. They differ in the way the material is handled or the country of origin, resulting in differences in function, feel, and gloss. Bamboo, cotton, and wool are natural fibers that will be more skin-friendly and more comfortable than other materials, and our factory also has OEKOTEX-100 environmental guarantee for these materials, suitable for the European market.

In addition, nylon is divided into ordinary nylon, recycled nylon, micro-nylon, and so on. Polyester also has 3 different types. The main difference is reflected in the softness and price.

Other conventional materials, including these two types of raw materials, are synthetic fibers, which are better than natural fibers in wear resistance and pilling resistance.

Therefore, sports socks, including sports compression socks, are usually made of nylon, while compression socks suitable for daily office wear or flight wear are usually made of natural fiber to improve comfort and moderately reduce compression.

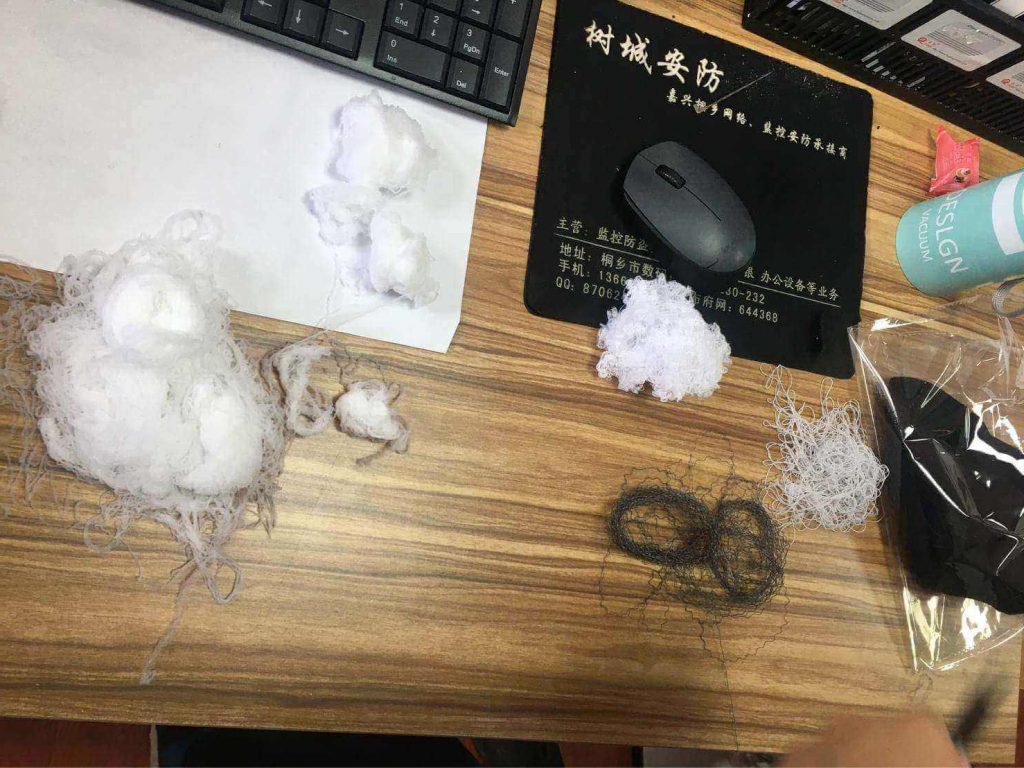

In the following picture, we can see that the flocculent yarn inside the socks is nylon or polyester, and this part of the socks is shown as the pattern outside.

Material of jacquard and elastic

The general raw materials mentioned above are mainly used on the surface of socks as the main component of socks. The pattern part usually uses nylon or polyester, because the colors of these two raw materials are brighter and can better highlight the pattern effect. Therefore, the pattern and logo parts of socks are usually made of nylon or polyester. So what’s the difference between these two raw materials?

First of all, in terms of raw material color, nylon looks brighter than polyester. Secondly, nylon is softer than polyester. The method of distinction is also very simple, usually by burning.

You can pull some yarn out of the socks to burn. Polyester will emit a lot of black smoke, nylon will emit white smoke, and we can also see the burning residue. Polyester can be crushed, and nylon will be like plastic. As a result, nylon is more expensive than polyester.

Apart from the main yarn and jacquard patterns, the rest composition on socks is spandex and elastic. All socks are made with spandex to increase elasticity, and compression socks need more elastic to support their compression due to their special functional structure, so the composition of elastic will be more than ordinary socks.

Spandex is commonly known as an elastic fiber, with high elasticity and strong flexibility; its stretch length can reach 5-7 times of the original fiber. Socks added with spandex can produce elasticity and be retractable, making them easier to wear and less likely to slip off.

If you have paid attention to the hanging tags of compression socks you will find that s you will find that some compression socks have Lycra written on their composition. Lycra is actually a kind of spandex fiber. It is a unique man-made elastic fiber invented and produced by DuPont in 1958, which can be mixed with a variety of man-made and natural fibers to increase the resilience of socks.

In layman’s terms, Lycra is spandex. What makes Lycra different from traditional elastane is that it stretches up to 500% and returns to its original shape. This means that this kind of fiber can be stretched very easily, but when it returns, it sticks to the surface of the body with very little binding. And unlike most spandex yarns, Lycra has a special chemical structure that prevents mold from growing in hot and humid sealed spaces, and also allows the socks to last for a long time. The spandex used in our factory’s compression socks is the default Lycra elastic, which is one of the reasons why our socks can be worn in longer times.

In addition to the body of the sock, there are two other parts that often use thick elastic bands.

One is the opening of the sock, where a 3*1 elastic is added to give a better fit around the leg or ankle, usually in short sports socks. Some socks are also made with arch support, which is usually placed in the middle of the foot to tighten the foot during exercise and increase its bounce.

Composition of compression socks

From the above, we know that the basic components of compression socks are the main yarn, jacquard yarn, and spandex. So, how to determine its percentage?

Let’s take the example of a normal dress sock. The following picture is an ordinary dress socks.

Assuming that the main yarn is cotton, we find that the jacquard part takes up roughly 30% of the socks, while spandex usually takes up around 5-10% of the socks (as the elastic fiber is the lightest weight). So we can roughly judge that the composition of the following socks to be 60-65% cotton, 30% nylon/polyester, and 5-10% spandex.

The proportion of the jacquard part is affected by the pattern, so the composition ratio of socks can not be made as required; it needs to be judged according to the actual pattern.

Compression socks reach the compression through elastics, so the composition is high, to roughly 40-50%, and the remaining material is divided into the main yarn and the jacquard part.

The following picture gives you a reference to how our factory usually judges the specific composition of socks. We need to tear down a sock and then determine the percentage of the overall socks by their different gram weights.

Here is another point of knowledge: there is no such thing as a sock with 100% of a certain composition. We can say that socks are made of 100% cotton, but because socks contain spandex, the maximum percentage of cotton is around for 95%. Generally speaking, cotton socks with a proportion of 75% can be called 100% cotton socks.

If you are not sure what kind of composition should be used to make your socks, feel free to consult us, Jiaxing Max Hosiery! Since 2021, our factory has been expanded to 80730square feet and increased our production buildings to three.

Whether you are a large company or a small business, we sincerely invite you to become our partner!

FAQ

1. What specific materials give compression socks their unique function?

High-quality compression socks are made from a precise blend of synthetic fibers. Spandex (or Lycra) provides the elasticity needed for graduated compression, while durable materials like nylon or polyester offer structure, moisture-wicking properties, and a comfortable feel against the skin.

2. How does the fabric’s composition determine the compression level (mmHg)?

The compression level (e.g., 20-30 mmHg) is created by the amount and tension of the elastic fibers, like spandex, woven into the fabric. A higher percentage of spandex and a tighter, more advanced knitting technique result in a higher mmHg pressure rating, offering firmer therapeutic support.

3. Can the materials in compression socks cause discomfort or skin issues?

While rare, irritation can occur if the socks are too tight or if you have a sensitivity. Quality blends are designed to be breathable and moisture-wicking to prevent this. If you experience discomfort, ensure your sizing is correct and consider materials specifically labeled as hypoallergenic or extra soft.

4. Are there alternatives if I find the material of a full sock unsuitable?

Yes. Compression leg sleeves offer the same graduated pressure for the calf but are made without a foot portion. For adjustable pressure, compression wraps use overlapping hook-and-loop fabric straps. However, only a full sock provides critical compression that includes the ankle and foot.

5. Why is a nylon/spandex blend better than simpler elastic or rubber?

Modern blends of nylon and spandex are superior because they provide precise, long-lasting compression that won’t degrade quickly. This composition is also more breathable, moisture-wicking, and comfortable for all-day wear compared to basic elastic or rubber, which can trap heat and irritate the skin.