Custom No Show Socks Manufacturer

Transform your brand with a proven manufacturing partner. We provide the full service—from concept to delivery—for premium no-show socks engineered for durability & performance.

Min. Order (Pairs)

Response Time

Countries Served

Choose styles by scenario—performance training, everyday comfort, or specialty looks. OEM/ODM support in technical blends, tuned height/cushion, retail-ready packaging, and OEKO-TEX® materials help you launch faster with consistent quality and predictable lead times.

Performance & Athletic

Invisible Trainer Socks

Offers maximum durability for high-impact sports with a reinforced heel and toe.

Athletic No Show Socks

A strategic compression arch provides enhanced stability and a secure, non-slip fit.

Moisture-wicking No Show Socks

Utilizes premium CoolMax® fibers (or your custom tech) to keep feet dry and cool.

Everyday & Casual

Cotton Loafer No Show Socks

A true low-profile cut in breathable cotton for all-day comfort in loafers or slip-ons.

Mens Low Cut No Show Socks

Slightly higher coverage reduces chafing; cushioned footbed and arch support for casual, everyday wear.

Invisible Socks

Below-ankle profile disappears in most shoes; snug, no-slip fit helps prevent blisters and keeps feet dry.

Specialty & Style

Ultra Low-Cut Ballet Socks

Ultra-low profile for ballet flats; seamless toe and silicone heel grip keep liners hidden and secure.

LaceTrim Invisible Socks

Delicate lace liner for heels and flats with anti-slip silicone bands; breathable, lightweight, and discreet.

Need a Custom Solution?

We specialize in creating unique no show sock designs tailored to your brand's specific needs and market positioning.

No Show Socks Details & Features

Advanced Silicone Heel Grip

Heel slippage is the #1 reason for customer complaints and returns. Our advanced silicone grip technology is your insurance policy. We engineer a grip that provides a reliable, all-day hold without irritation.

- Less friction, fewer blisters — A secure heel reduces rubbing and hot spots typically caused by no-show socks that drift.

- Skin-friendly materials — We use silicone options that are non-toxic and hypoallergenic, suitable for prolonged skin contact.

- Tested for 100+ washes maintaining grip strength for long-lasting customer loyalty

Ultra-Low Cut Design

Keep liners invisible—even in ballet flats and low-vamp loafers. Our ultra-low patterns cover only toe and heel while a discreet opening and optional heel grips help the sock stay put without peeking.

- Extensive Fit Testing: We test our cuts against hundreds of popular shoe models (loafers, flats, heels, trainers) to ensure a perfect, no-show fit for every style.

- Comfort-focused edge with smooth openings to reduce rubbing in tight shoes.

- Stay-put options (toe/heel grip placements) to prevent slippage in extra-low silhouettes.

Moisture-Wicking & Odor Control

Dry feet mean happier customers and fewer returns. We use moisture-moving yarns (e.g., COOLMAX®/performance poly) and optional anti-odor tech (e.g., silver ion finishes) to manage sweat and help limit odor build-up.

- 3x faster drying than standard cotton keeps feet comfortable in any climate

- Odor-control options with silver-based technologies that target odor-causing bacteria.

- Comfort toe details (flat/linked seams) to reduce hot spots during wear.

Reinforced Construction

Holes are brand killers. Reinforced heel-and-toe zones and abrasion-tested yarns extend wear life, while smooth seams help cut friction complaints.

- 200-needle gauge knitting creates dense,tear-resistant fabric that lasts

- Y-heel construction prevents bunching and extends product lifespan

- Heel/Toe reinforcements for higher wear resistance where socks fail first.

Ideal Applications of No Show Socks

Ballet Grace

Soft, flexible, and invisible socks that move naturally with every step. Perfect for ballet shoes with slip-free comfort.

Active Sports

Breathable and supportive design that stays in place during workouts, keeping your feet dry and comfortable.

Daily Comfort

Light, invisible, and soft. Ideal for everyday wear with sneakers or casual shoes, ensuring all-day freshness.

Why Global Brands Choose Max Hosiery

Lightning-Fast Response

Get detailed quotes and free design mockups within 24 hours. No waiting, no delays - just results.

Full Customization Service

From logo and color to packaging and labels, we support one-stop OEM service tailored to your brand's style and user needs.

In-House Manufacturing

Complete control over quality and timelines with our own 20,000㎡ facility and 170+ skilled workers.

3-Year Product Warranty

We stand behind our quality with the industry's best warranty coverage and dedicated after-sales support.

Customize Every Aspect of Your No Show Socks

As a custom grip-socks manufacturer, we give you end-to-end OEM control—Pantone-matched colors, sizing, logo integration, material selection, retail-ready packaging, and fully adjustable grip patterns—so your private-label socks hit exact performance specs and stand out in search.

Custom Colors

Match your brand colors perfectly with Pantone dyeing process.

Custom Logos

Integrate your branding seamlessly. We can knit logos into the sock or mold them directly into the silicone grip pattern.

Material Selection

Select the perfect blend for your performance and price targets. Full expertise in CoolMax®, Merino Wool, Organic Cotton, Bamboo, and viscose/rayon for a cool, silky touch.

Custom Sizes

Develop a full size run, from children to adult. We provide custom fit options and grading for any international market.

Custom Packaging

Retail-ready multi-pair packs with belly bands, header cards with hooks —barcode/size stickers and compliance copy included for quick planogram placement.

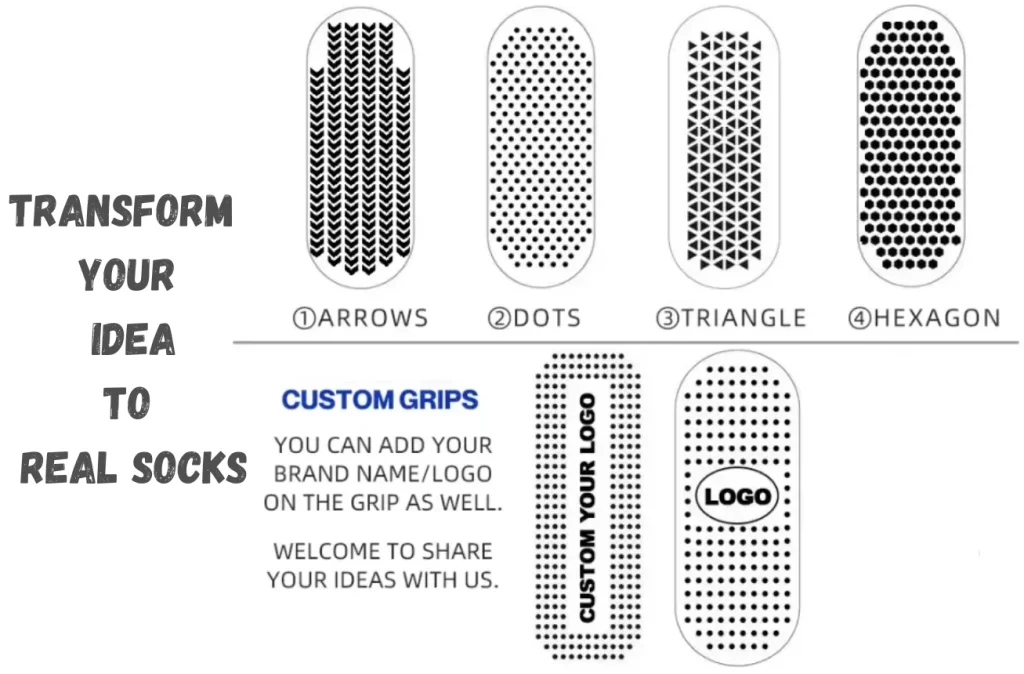

Custom Grips

Customize grip layouts and density dots, lines, logos to match performance needs and price points.

Your Custom No Show Socks Timeline – From Idea to Delivery

Select road, trail, speedwork, or seasonal to preview the best-fit heights, cushioning, and blends for each environment—then add styles to your quote or sample list.

Inquiry & Consultation

Share your project details, and our experts will reply within 24 hours with price and solutions.

Sample Development

We craft samples to your specs and send approval photos within 3-7 days.

Sample & Order Confirmation

Confirmation Review your samples and request any refinements. Upon approval, we finalize your order details with a deposit to begin production.

Bulk Production

Production time varies by quantity; regular production time is 3-4 weeks.

Quality Inspection & Shipping

We will ship the bulk order after QC inspection. Choose between express air shipping (5-7 days) or sea freight (3-5 weeks) for most areas.

Questions For No Show Socks Customization

What is the minimum order quantity for custom no-show socks?

Our standard MOQ starts from 1,000 pairs per design, with mixed sizes allowed in the same order. For new programs or test orders we can discuss flexible quantities to help you validate the market before scaling.

How long do sampling and bulk production take?

Artwork & details confirmed → samples in about 7–10 days; bulk production typically 25-30 days after sample approval and deposit, depending on spec and quantity. We align timelines with your launch schedule and repeat orders to keep shelves in stock.

Can you support testing, compliance and audits for our buyers?

We can use OEKO-TEX® Standard 100 certified materials (on request) and arrange color fastness, washing, and durability tests through qualified labs. Factory documentation and necessary reports are provided to support retailer and importer standards.

Can you work with specific yarns like COOLMAX®, bamboo, organic cotton, merino, or “ice silk”?

Yes. We offer custom blends including COOLMAX®/performance polyester, bamboo-viscose, organic cotton, combed cotton, merino wool and cooling “ice-silk” styles, matched to your target price and positioning. Fiber content and care instructions are labeled correctly to meet import requirements.

What packaging options are available for retail programs?

We support multi-pair packs (3/5/6/10 packs), belly bands, header cards with hooks, hangtags, boxes and e-commerce-ready polybags. All packaging can include barcodes, size charts and your branding for direct-to-shelf display.

How is my custom design and branding protected?

Your tech packs, logos and patterns are treated as confidential and produced exclusively for your brand. We do not show or supply your custom designs to other buyers.

Still have questions?

Our experienced team guides you through every step of the process, from design to delivery, helping you avoid common pitfalls and create exceptional custom socks.

Latest from Our Blog

Stay updated with the latest trends, technologies, and insights in the custom sock industry to help grow your brand and enhance your product offerings.

See how shifting fashion trends, Gen Z preferences, and visible-sock hype are impacting demand—while no show socks still win in key niches like flats, loafers, hot climates, and “sockless” dress codes. Use these insights to fine-tune your assortment instead of dropping no shows blindly.

Learn how grip socks improve stability and performance in sports, fitness, and medical use—and why brands choose custom grip sock solutions for better traction and market value.

Learn how Acceptance Quality Limit (AQL) sampling protects your brand by filtering out critical, major and minor defects before compression socks leave the factory. This practical guide explains AQL 1.5 vs 2.5, sampling charts, and defect classification, ensuring every shipment meets industry expectations and reduces costly returns for you.