Why Custom Pilates Grip Socks Help Studios Stand Out and Earn More

Pilates and barre studios commonly require wearing something on the feet for safety and hygiene reasons. In many cases clients buy Pilates/Yoga socks, such as these samples on our Pilates Socks Collection Page, from third-party brands, so the associated revenue and brand exposure do not stay with the studio. Establishing a custom, studio-branded grip sock program centralizes product quality control, aligns appearance with the studio’s visual identity, and creates an additional high-margin retail category. This article outlines the main decisions involved in production, branding, inventory management, and pricing, from a studio operations perspective.

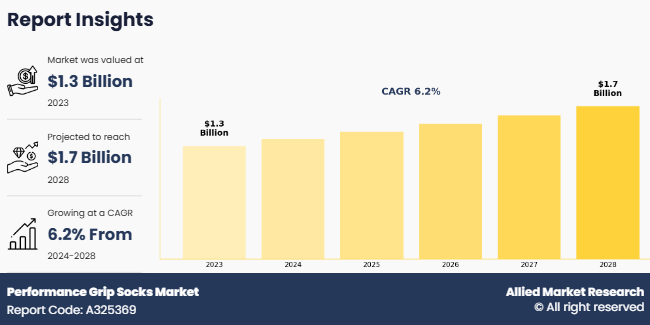

Market Opportunity: Where Grip Socks Sit in Your Retail Mix

Grip socks have moved from “nice to have” to “standard equipment” in many studios. That shift creates a predictable, repeatable retail category.

- High share of retail: In many studios, grip socks account for roughly 15–25% of retail sales, with multi-location businesses reaching five-figure annual revenue purely from socks.

- Healthy gross margins: Compared with apparel, custom socks are relatively low in size complexity and high in markup, often supporting 60–75% gross margins.

- Built-in demand: New clients, forgetful members, and gift buyers continually refresh demand.

Positioning Against Other Options

| Category | Typical Retail Range | Margin Level | Main Advantage |

|---|---|---|---|

| Premium studio-branded | $16–22 | High | Exclusive design, premium feel, strong brand identity |

| Mid-tier studio-branded | $12–16 | Med–High | Reliable quality, logoed, small-batch or seasonal options |

| National fitness brands | $10–18 | Medium | Known labels, easy to restock, generic styling |

| Semi-custom private label | $10–18 | Medium | Studio name on packaging, flexible seasonal assortments |

Production Options: Evaluating Manufacturing Approaches

Choosing where and how to make your socks comes down to a balance of speed versus cost.

Domestic vs. Offshore

If you’re doing a small “limited edition” run or need socks yesterday, domestic production is your best bet. Communication is easy, and shipping is fast, though you’ll pay a higher price per pair. Offshore manufacturing is where you maximize profit. It takes longer (plan for lead times), but the unit cost drops significantly, and you get more options for custom grip patterns and technical yarns.

Customization Methods and Options

- Sock structure

Fiber blend (cotton, synthetic, bamboo), Thickness, Cushioning Zones (heel/toe/forefoot), Arch Compression, and Sock Length (no-show, ankle, crew). - Grip design

Shape, size, and density of grip dots or patterns, as well as full-sole vs targeted grip layouts. - Logos and branding

Logo placement on the cuff, top of foot, or sole; execution via knit-in patterns, heat-transfer prints, or limited embroidery. - Color matching

Body, cuff, and grip colors matched to brand guidelines, often using Pantone or similar color references. - Packaging

Branded tags, sleeves, bands, or small boxes/pouches with custom artwork, sizing, care instructions, and pricing.

Careful planning ensures your socks not only represent your brand well but also meet your clients’ expectations on comfort and durability. For a full overview of available options, explore our custom sock design and manufacturing page.

Material Selection: Balancing Function, Feel, and Cost

Material choice determines how Pilates and yoga socks feel, how they handle sweat, how long they last, and what they cost per pair.

Fabric options

Most Pilates and yoga socks use blends of several fibers. Common options are:

- Bamboo blends (bamboo viscose + cotton/synthetic + elastane)

Smooth touch and comfortable against bare skin. Often handles odor better than basic cotton. Yarn cost is typically higher. Durability depends heavily on knit density; a tighter knit helps offset the softer yarn. - Cotton-rich blends (cotton + synthetic + elastane)

Soft touch and familiar feel. Breathable in normal studio conditions. Sweat management and shape retention are moderate. Yarn cost is usually mid-range. Lifespan is acceptable for regular use, but heavy, high-sweat users may see wear sooner than with synthetic-rich options. - Synthetic-rich blends (polyester/nylon + elastane)

Less “natural” in hand-feel, but better at moving moisture and keeping shape after frequent washing. Often more resistant to pilling and thinning at the heel and toe. Yarn prices vary but are usually competitive for larger runs. A practical choice for studios with high-class frequency or clients who train several times a week.

Grip materials and layout

- Silicone grip

Widely used, stays flexible, and tolerates repeated washing. Higher-grade silicone compounds usually maintain grip and elasticity longer, with a modest cost increase per pair. - PVC grip

Typically lower cost per pair. Provides basic traction at the start, but may harden or crack faster under frequent washing and use. Less suitable for brands that emphasize reduced plastic use or sustainability claims.

For a deeper comparison of grip compounds and how they perform over time, see our detailed guide to grip sock materials and grip layouts.

Grip coverage and pattern influence both performance and cost:

- Larger coverage areas use more material and add grip, but can reduce sole flexibility and slightly increase cost.

- Targeted patterns (heel, ball of foot, toes) use less material, keep the sock more flexible, and reduce cost, but require accurate placement to avoid slipping in specific positions.

Before locking in a specification, it is practical to test samples on your own floors—both dry and lightly damp—and after multiple wash cycles, then select the combination that meets your studio’s expected usage and price point.

Design & Branding: Creating Your Next Best-Seller

Aesthetics That Drive Sales

- Trending Color Palettes: Move beyond basic black. Current best-sellers in the boutique space utilize tonal aesthetics—think sage greens, muted terracottas, and “oatmeal” neutrals. These shades feel high-end and are much more likely to be featured in a client’s “workout OOTD” (Outfit Of The Day) social post.

- Textural Contrast: Mixing materials adds immediate perceived value. Consider adding mesh panels on the top of the foot for a delicate, breathable look, or ribbed textures on the cuff that mimic high-fashion streetwear.

- The “Signature” Grip: Don’t waste the real estate on the sole. Customizing the silicone grip into a unique pattern—like stars, waves, or your studio’s monogram—makes the sock feel exclusive. It’s a “hidden” design detail that clients love to show off.

Packaging: Turning a Purchase into an Experience

In a retail environment, the packaging does the heavy lifting for the sale. It’s the difference between a “commodity” and a “gift.”

- Gift-Ready Presentation: If you are launching a seasonal collection, consider multi-pack boxes or custom zipper pouches. These increase the average transaction value by encouraging clients to buy three pairs instead of one.

- Belly Bands & Matte Sleeves: A thick, soft-touch paper wrap with clean typography is the gold standard for boutique retail. It feels premium to the touch and allows your brand story to shine without hiding the sock’s design.

How to Ensure Consistent Quality in Custom Grip Socks

When you offer custom grip socks to your clients, consistent quality is key. Every pair needs to meet your studio’s standards for performance, durability, and appearance. Otherwise, issues like slipping grips, uneven fit, or fading colors can hurt both your brand and sales.

That’s why quality control should be an integral part of the manufacturing process, not an afterthought. Here’s how to make sure your custom socks deliver every time.

Define Clear Quality Standards from the Start

Before production begins, work with your manufacturer to agree on what quality means for your socks. Key areas include:

- Grip effectiveness: The socks should provide reliable traction on both dry and lightly damp surfaces, and maintain grip after repeated washing.

- Durability: The socks must hold their shape, cushioning, and grip pattern after many washes without thinning or fading.

- Fit consistency: Each size should match agreed measurements within a small tolerance, ensuring a comfortable, secure fit for your clients.

- Color accuracy: Brand colors need to be consistent across production batches to maintain your visual identity.

- Seam and construction quality: Socks should be free from loose threads, uneven stitching, or weak spots.

Keeping approved sample pairs helps to compare future runs and quickly spot any variations.

How We Support Your Quality Assurance

We understand that quality control can feel complex, especially for new custom sock projects. That’s why we:

- Provide production samples early for your review and approval.

- Maintain clear communication throughout the manufacturing process.

- Implement stage-by-stage inspections, including checks before cutting, mid-production samples, and final goods review.

- Offer assistance with third-party testing when needed to validate grip performance, color matching, and material durability.

- Build long-term partnerships to ensure stable quality and smooth reorder processes.

Why Quality Control Benefits Your Business

Reliable quality protects your studio’s reputation and builds trust with your customers. Consistent products reduce returns and complaints, improve client satisfaction, and help your brand stand out in a crowded market.

By collaborating on quality standards and monitoring production closely, you can confidently offer custom grip socks that reflect your studio’s professionalism and values.

Inventory Management: Balancing Stock and Cash Flow

Managing inventory well is key to making custom grip sock programs profitable while keeping products available for customers. Smart ordering, stocking, and restocking help studios balance money tied up in stock with sales chances.

Optimizing Order Quantities and Forecasting Demand

Ordering the right amount depends on many factors: minimum order sizes, price breaks, storage space, cash flow, and expected sales. New custom sock lines often require some guesswork, but studios can use current sock sales as a guide. Custom products may increase sales by 20-30%. Size matters too. Typically, women’s medium sizes make up 40-50% of sales, followed by small (20-30%) and large (15-20%), though each studio’s mix varies. Planning reorder timing is important — order early enough to cover production lead times plus extra time to avoid running out. Even simple tracking systems or spreadsheets can help spot sales trends and reorder points. For studios with multiple locations, managing inventory centrally and moving stock between stores keeps overall levels balanced. Remember seasonal shifts—sales usually rise during new client periods (January-February, September-October) and gift seasons, so plan accordingly.

Storage, Display, and Carrying Costs

Grip socks don’t need much storage space—about 3-4 cubic feet for 500 pairs—but organizing stock by size saves time and prevents over-ordering. Where socks are displayed matters; placing them near checkout can increase impulse buys by 30-50%. Keep displays full and sizes clearly labeled to help sales. Carrying costs—the money tied up in inventory, plus storage and handling—usually range from 15-25% of stock value yearly. For limited space, ordering smaller, more frequent batches may work better, even if unit costs are slightly higher. Conduct regular inventory checks (every few months) to avoid errors and shrinkage.

| Action | Why It Matters | Tip |

|---|---|---|

| Order balanced quantities | Saves money, meets demand | Use sales data to guide orders |

| Track size demand | Avoids overstock or stockouts | Focus on top-selling sizes |

| Reorder early | Prevents running out | Add buffer to lead time |

| Display prominently | Boosts impulse sales | Keep displays fully stocked |

| Audit inventory regularly | Maintains accuracy | Schedule quarterly checks |

Pricing Strategy: Balancing Revenue and Perceived Value

Setting the right price for custom grip socks is key to maximizing both revenue and customer appeal. A well-planned pricing strategy balances costs, desired profit margins, and the value your brand delivers.

Price Positioning and Margins

Custom grip socks typically cost 25-40% of their retail price to produce, plus shipping (3-8%), inventory costs (3-5%), and potential sales commissions (10-15%). Considering these, studios often price retail between $16 and $22. This premium pricing reflects the added value of studio branding and exclusivity compared to generic socks priced around $12-$16. At these prices, gross margins usually range from 60% to 75%, supporting healthy profitability.

Some studios offer tiered pricing to meet different client needs. Standard options sit within the $16-$22 range, while premium versions—featuring higher-quality materials, special designs, or gift packaging—can reach $24-$30. Bundling socks in multi-pair packages or pairing with other studio products encourages larger purchases while offering clients a sense of value.

To address price sensitivity, focus on emphasizing performance benefits, brand exclusivity, and unique design elements rather than just basic features. This helps justify the higher price compared to off-the-shelf options.

Promotional Strategies

Limited-time offers can increase sales velocity without hurting overall margins. Examples include discounted first-pair specials for new clients, referral discounts, and seasonal promotions around gift-giving periods. Integrating socks into loyalty programs rewards repeat buyers and builds brand loyalty.

Bundle promotions combining socks with complementary items (water bottles, towels) or studio services also raise average transaction sizes. Studios with multiple locations or large client bases can use limited-edition designs or seasonal colors to create urgency and encourage full-price purchases.

Clear promotion timeframes and policies help avoid clients expecting permanent discounts. Tracking promotion results enables studios to refine strategies for the best returns.

Marketing and Promotion: Building Awareness and Demand

Strategic marketing can turn custom grip socks from mere stock into popular studio essentials and gifts. Using multiple digital channels helps reach current clients and attract new customers effectively.

Digital Marketing Tactics

Social media platforms like Instagram and Facebook work well for fitness accessories. Posting high-quality product photos, action shots during practice, and user-generated content engages audiences. Instagram Stories are especially useful for announcing limited-time offers or new releases.

Email marketing remains a strong tool for driving sock sales. Dedicated campaigns typically achieve 15-25% open rates and 2-4% conversion rates when featuring attractive images and clear value messaging. Segmenting emails by client type—such as new visitors, frequent attendees, or past buyers—boosts results by delivering relevant content.

Studios should create dedicated website pages for grip socks with detailed information, compelling visuals, and easy purchasing options. Offering online pre-orders with in-studio pickup enhances convenience. For studios with e-commerce sites, online sock sales can expand beyond local clients to wider brand fans.

Targeted digital ads on social media and local search platforms help reach potential customers interested in fitness activities. With proper optimization, these ads can generate 3-5 times the advertising spend, making them cost-effective for studios.

Summary: Key Marketing Channels

- Social Media: Visual posts, user content, Stories for promotions

- Email: Segmented campaigns with strong imagery and clear offers

- Website: Dedicated product pages, online pre-orders, e-commerce options

- Digital Ads: Targeted local promotions with measurable ROI

These approaches combine to raise grip sock visibility, increase demand, and support studio retail growth.

In-Studio Promotion and Merchandising Excellence

A well-executed in-studio display turns grip socks into must-have studio gear. Here’s how to make it work:

Strategic Visual Merchandising

- Prime Placement: Position displays near check-in or high-traffic areas.

- Full Stock: Keep displays topped up—empty spots can cut sales by up to 25%.

- Benefit-Focused Signage: Highlight grip, hygiene, and brand exclusivity instead of price.

Staff and Class Integration

- Uniform Promotion: Have instructors and front-desk staff wear and demo the socks.

- Natural Mentions: Instructors reference sock benefits in class; include grip socks in new-client guides.

- Special Events: Host “sock-required” workshops or demo days to drive trials.

Local Partnerships and Multi-Location Consistency

- Collaborations: Team up with nearby wellness vendors for holiday gift bundles or cross-promotions.

- Brand Standards: Use the same display templates, signage, and merchandising guidelines across all sites for a unified look and easier inventory management.

| Marketing Channel | Implementation | Metric |

|---|---|---|

| Social Media | Product photos, class action shots, client tags | Engagement rate, link clicks |

| Email Marketing | Sock-focused, segmented campaigns | 15–25% open rate, 2–4% conversions |

| Website | Dedicated sock pages, online pre-order options | Page views, purchase rate |

| In-Studio Displays | Prominent placement, attractive setup, full restocking | Sales per visit, display conversion |

| Staff Demonstration | Team members wearing and talking up the socks | Conversations generated, feedback |

| Class Integration | In-class mentions, orientation packets, pop-up events | Trials booked, awareness uplift |

Conclusion: Building a Profitable Studio Grip Sock Program

Launching a custom grip sock program can offer both financial and branding benefits—when approached with strategic planning. Studios that view sock retail not as a side offering but as a structured business channel tend to see stronger results, especially when they align the program with their broader brand and client experience.

Custom grip socks offer more than just merchandise. They reinforce studio identity, meet functional client needs, and open a new revenue stream that extends beyond class fees. When socks are thoughtfully designed and clearly differentiated from generic alternatives, clients are more willing to pay a premium. This makes it easier for studios to maintain solid margins while delivering real value.

Success often depends on how well each part of the program is managed. High-quality production, effective staff training, well-timed promotions, and cohesive visual merchandising all play a role. Equally important is making the socks feel like a natural part of studio life—integrated into instructor mentions, orientation materials, and daily use by staff.

A phased approach works best for most studios. Starting with smaller batches allows time to test product quality, refine size selection, and collect client feedback. Staff can be gradually trained in product knowledge and soft selling techniques before scaling inventory or marketing spend. This lowers risk while increasing the chances of long-term success.

With the right planning and steady execution, custom grip socks can become more than just another retail item—they can strengthen your brand, generate consistent revenue, and create deeper connections with your community.

FAQ About Pilates Grip Sock Production

What are the typical minimum order quantities for custom grip sock production?

Domestic factories often start at 100–200 pairs. Offshore options usually require 300–500 pairs. Fully custom designs with special grips may need 500+ pairs. Lower quantities are sometimes negotiable but usually cost more per unit.

How do production costs compare between domestic and offshore manufacturing?

Offshore socks cost $2.50–$4.00 per pair. Domestic ones cost $4.00–$6.00. Domestic production offers faster lead times, lower MOQs, easier communication, and better quality control, which may justify the higher cost.

What are the most effective retail price points for studio-branded grip socks?

$16–$22 is common for custom grip socks. It supports 60–75% gross margins. Some studios offer premium models at $24–$30, while keeping basic styles lower for price-sensitive clients

How can studios forecast appropriate size distributions for initial orders?

Women’s medium makes up 40–50% of demand, followed by small and large. Studios should review client data or survey customers to plan size splits based on their specific audience.

What quality issues should studios watch for when evaluating grip sock samples?

Test grip adhesion, wash durability, fit, seam strength, and traction. Check for shrinkage and color fading. Try on multiple foot types to ensure comfort and consistent sizing across pairs.