Custom Calf Compression Sleeves Manufacturer

Looking for a reliable partner? We manufacture sleeves targeting specific needs, including calf compression sleeves for varicose veins and specialized compression sleeves for calf injury recovery. Explore our extensive customization options—including white calf compression sleeves, xxl sizes, and breathable materials.

MOQ Pairs

Registered

13485

Daily Calf Support Compression Sleeves

Scalable production for mass retail, supporting inclusive sizing systems from youth to plus size demographics.

- Wide calf & XXL molds available

- Standard Circulation: 15-20 mmHg

- High-elasticity womens & mens fits

Medical Grade Compression Calf Sleeves

Manufactured on Lonati and Merz medical-grade knitting machines to ensure precise graduated pressure for vein therapy and rehab product lines.

- Therapeutic Grade: 20-30 mmHg

- Targeting varicose veins relief markets

- Post-op calf injury support structure

Calf Muscle Compression Sleeve for Sports

Durable construction designed for athletic brands, featuring zoned compression for running and agility sports.

- Shin splints vibration dampening tech

- Heel support for pain relief

- Reinforced for basketball & calf strain

Functional Compression Calf Sleeve

Differentiate your catalog with functional infused fibers and thermal-retention materials for specialized applications.

- Copper infused calf compression sleeve yarn

- Adaptive Pressure: 20-30 mmHg

- Cushioned sole for comfort

Details That Make the Difference

Every feature is designed to reduce your after-sales issues, strengthen your listing ratings, and give your customers a reason to come back.

Double-Reinforced Stitching

Both top and bottom cuffs are double-stitched for long-term durability — fewer returns from unraveling edges means lower after-sales cost and stronger review scores.

Non-Slip Silicone Grip Cuff

Inner silicone dot matrix keeps the sleeve locked in place during all-day wear and high-intensity movement — a must-have for medical compression and athletic recovery channels where slip-free fit is a core purchase driver.

Anti-Slip Yarn Technology

Our proprietary anti-slip yarn is knitted directly into the cuff structure, preventing rolling and sliding from the fiber level. A built-in performance advantage that holds up wash after wash — not a surface treatment that fades over time.

Reflective Elements

Heat-bonded reflective strips provide 360° low-light visibility — one feature that instantly opens the running and night cycling market for your brand.

Specialized Features Available

Zipper

Easy on and off with a convenient zipper closure for those with limited mobility

Full Print & Dye

Tie-dye, sublimation, and 360° seamless printing available. Turn any design into a finished product.

Copper-Infused

Advanced copper fiber technology provides natural antimicrobial protection and odor control

Wide Calf

Extra wide design accommodates larger calves up to 25+ inches for comfortable all-day wear

What We Can Customize For You

From compression levels to packaging — every detail can be customized to fit your brand and sales channel.

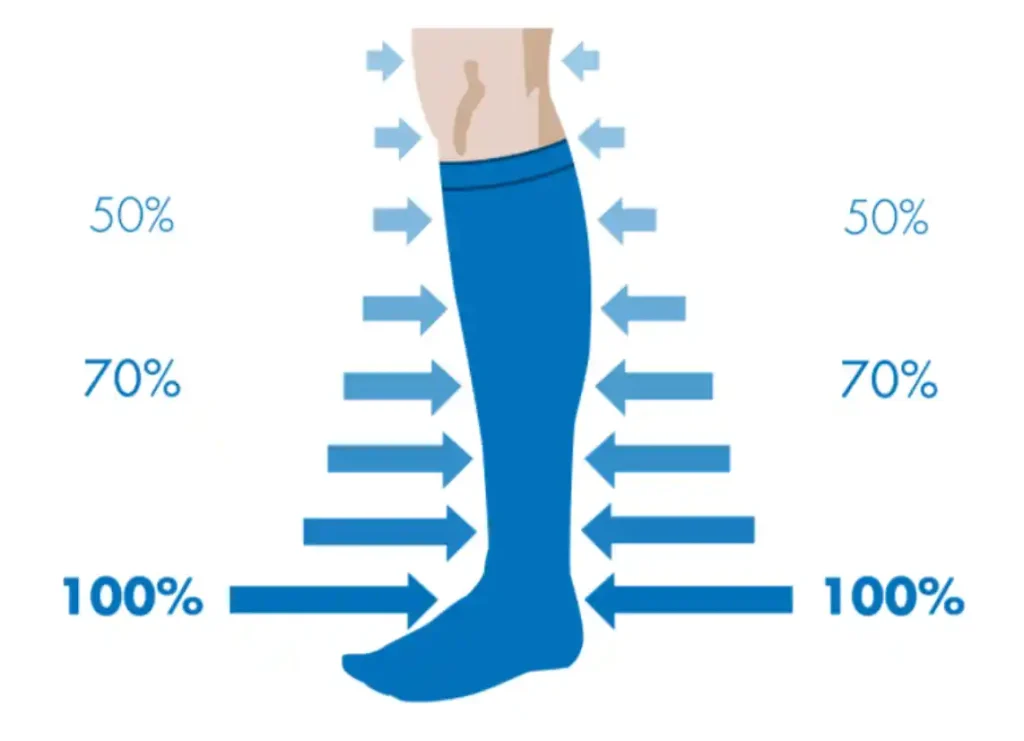

True Compression Levels

Ideal for travel, desk jobs, and early pregnancy. Popular with travel brands, nurse/workwear lines, and maternity products.

Recommended for varicose veins, pregnancy, and post-surgery recovery. Suitable for pharmacy channels, medical suppliers, and healthcare brands.

Clinical-level support for DVT, severe edema, and prescription use. Designed for medical distributors and hospital supply chains. Requires proper sizing guidance.

💡 Not sure which level fits your market? [How to Choose the Right Compression Level →]

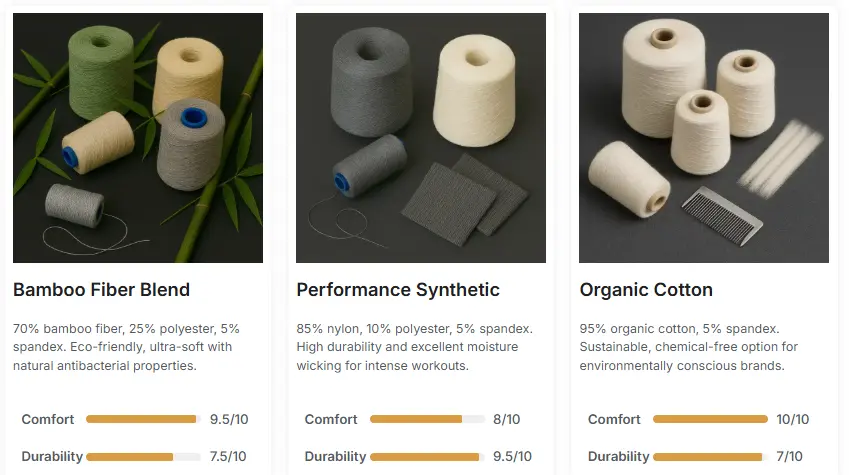

Superior elasticity retention and silky hand feel — built for brands competing on quality in the medical, recovery, and professional sports segment.

Strong durability with vibrant color fastness at a competitive cost — the go-to choice for high-volume wholesale and eCommerce brands where margin matters.

Breathable, hypoallergenic, and soft against skin — ideal for everyday wellness brands, pharmacy channels, and sensitive-skin collections.

NEEDLE OPTIONS

We offer full specifications. Choose 144N-200N for sports use, or upgrade to 300N-420N for a second-skin feel targeting vein therapy. High density ensures superior lateral stretch, ideal for extra-wide calf requirements.

- 168N - 240N Options: Durable, Breathable, Athletic Focus

- 300N - 420N Options: Ultra-Fine, Medical Grade Finish

- Graduated Compression: Precise mmHg Accuracy

Packaging Options

Custom packaging such as header cards, labels, wrap bands, or individual boxes with your branding. We can also print your barcodes or provide custom poly bags.

- Display & Gift Box

- Branded Packaging Design

- Sustainable Packaging Options

- Amazon-friendly vacuum-sealed packaging

Expand Your Product Line: Strategic Bundles

Stay ahead of market trends with our curated product combinations. These best-selling pairings are designed to solve real-world athlete problems—from shin splint relief to match-day grip—helping you launch high-demand categories faster and more effectively

Some customers prefer a sleeve without foot coverage. Others want a full sock from ankle to calf. Offering both means your brand covers every preference — and both are built on the same compression standard from the same factory.

Unified Pressure Standard

Both products are manufactured on the same compression knitting system — ensuring consistent mmHg calibration and testing protocols.

Shared Brand Identity

One factory means identical color matching, fabric hand feel, and packaging design across both SKUs for a professional look.

One PO, One Shipment

Lower logistics cost, simplified sourcing, and a single point of contact from sampling to final delivery.

Cut the team sock, wear grip socks underneath, pull the calf sleeve over the top — this is how professionals play. When your brand offers both as a matched set, you are selling a system, not two separate products.

How Pros Wear It

Grip socks for traction, calf sleeve for support — this combo is already standard on the pitch.

Team Customization Ready

Matching team colors, crest placement, and numbering across both products.

Bundle = Higher Margin

Sell as a match day set — higher perceived value, better average order value.

Calf sleeves and arm sleeves share the same core technology — tubular knitting with graduated compression. Add knee braces and ankle supports, and your customers can find head-to-toe protection under one brand name. One factory producing the full range means consistent quality and a simplified supply chain.

One Factory, Full Range

Calf sleeve, arm sleeve, knee brace, ankle support — all from the same production facility.

Consistent Quality Across SKUs

Same yarn sourcing, same knitting standards, same QC process.

Scale Your Catalog Faster

Shared colorways, packaging templates, and size systems — less setup, faster time to market.

Compression Sock Assurance Center

We go beyond standard production. Our compression socks are developed and tested with specialized medical-grade equipment — including pressure testing machines, stretch resistance testers, and dedicated medical knitting machines. Certified to meet international standards for quality, safety, and performance.

Advanced Testing Machines

We ensure every pair meets strict pressure and durability standards.

Medical Merz & Lonati Machines

Compression Level Testing Machine

Socks Stretching Testing Machine

Frequently Asked Questions

Get answers to common questions about our custom calf compression sleeve manufacturing services.

What is the MOQ for custom compression calf sleeves?

Our standard MOQ is 500 pairs per color per size for OEM orders. For stock designs without customization, MOQ can be lower — contact us with your requirements and we will work out a plan.

Can you produce both mens and womens compression calf sleeves in the same order?

Yes. We offer a full size range from XS to XXXL, covering both mens compression calf sleeves and womens compression calf sleeves. We also support wide calf compression sleeves and plus size calf compression sleeves for brands targeting the US and European markets.

What compression levels are available, and how do I choose the right one for my market?

We produce four compression ranges: 8–15mmHg for daily comfort and travel, 15–20mmHg for sports recovery and running, 20–30mmHg for athletic performance and shin splint support, and 30–40mmHg for medical grade compression calf sleeves used in vein therapy and post-surgical rehab. If you are not sure which level fits your target market, our team will recommend based on your channel and end-use scenario.

Can your calf sleeves be used for specific conditions like shin splints, calf strain, or varicose veins?

Yes. Many of our OEM clients sell compression calf sleeves for shin splints, calf strain recovery, and varicose vein management. The key is matching the right compression level and material to the intended use. We can help you define the correct spec for each application and provide supporting test reports for your product claims.

How long does sampling take, and what is the production lead time?

Sample development takes 7–10 days after design confirmation. Bulk production lead time is typically 25–35 days depending on order volume and customization complexity. If you need calf compression sleeves for a specific launch date or seasonal campaign, let us know upfront and we will build a timeline that works.

What certifications do your compression calf sleeves carry?

Our products are manufactured in an OEKO-TEX certified facility. Depending on your market requirements, we can provide FDA registration, CE marking, and ISO 13485 compliance documentation. Every production batch undergoes independent pressure testing, and we include test reports with your shipment so you can verify compliance before selling.

Insights That Help You Source Smarter

Explore expert tips, industry trends, and practical guides on custom compression calf sleeves manufacturing, materials, certifications, and sourcing strategies. Whether you’re launching a new line or optimizing supply chains, our articles support informed decisions and better results.

Explore our in-depth guide to custom sock solutions—covering materials, advanced logo techniques, and eco-smart packaging—designed to help brands carve a unique identity, reduce costs, and accelerate speed-to-market. See real industry examples and discover how we turn concepts into globally successful product lines.

Explore the six critical elements that affect the cost of compression socks, including material selection, compression levels, manufacturing complexity, and certifications. This guide provides valuable insights for brands and retailers aiming to make informed sourcing decisions.

Choosing the appropriate compression level is crucial for meeting your customers’ needs. This guide provides five practical tips to help brands and retailers select the right compression levels, ensuring product effectiveness and customer satisfaction.

Ready to Start Your Calf Sleeve Project?

Tell us about your business and requirements. Our team will respond within 24 hours with personalized product recommendations and competitive pricing.

Inquiry & Consultation

Share your project details, and our experts will reply within 24 hours with price and solutions.

Sample Development

We craft samples to your specs and send approval photos within 3-7 days.

Sample & Order Confirmation

Confirmation Review your samples and request any refinements. Upon approval, we finalize your order details with a deposit to begin production.

Bulk Production

Production time varies by quantity; regular production time is 3-4 weeks.

Quality Inspection & Shipping

We will ship the bulk order after QC inspection. Choose between express air shipping (5-7 days) or sea freight (3-5 weeks) for most areas.

🔒Your information is secure. We’ll respond within 24 hours with a customized proposal.