Custom Compression Socks Manufacturer

Partner with a trusted manufacturer to create high-performance compression socks that solve real customer needs and elevate your product line.

MOQ Pairs

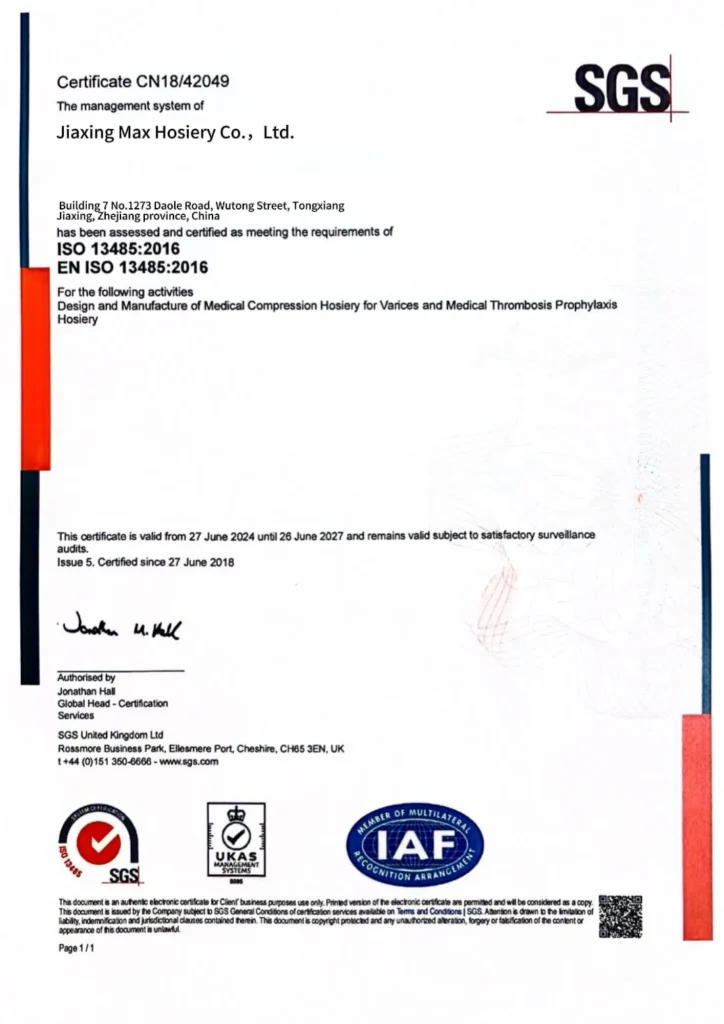

Registered

13485

Explore Our Compression Sock Categories

Seeking custom compression socks? We partner with you to design and manufacture high-quality solutions for diverse needs – from performance to wellness. Understand the possibilities, enhance your brand, and see how we craft the perfect socks for your customers. Explore our categories below to learn more.

Anti Embolism Stockings

- 18 mmHg hospital-grade compression

- Open toe for circulation monitoring

- Ideal for bedridden & post-operative patients

DVT Prevention Socks

- 20-30 / 30-40 mmHg medical grade

- Knee-high & thigh-high available

- For long flights, post-surgery & at-risk patients

Varicose Veins Socks

- 15-20 / 20-30 mmHg graduated compression

- Sheer & skin-tone options available

- Helps reduce visible veins & leg fatigue

- Lightweight & breathable mesh zones

- Arch support & blister prevention

- Ideal for marathon, trail & daily running

Sports Compression Socks

- Moisture-wicking & quick-dry fabric

- Cushioned sole for impact protection

- Multi-sport: gym, CrossFit, HIIT training

Cycling Compression Socks

- Reinforced heel & toe for durability

- 15-20 mmHg with calf support

- Post-workout & injury prevention

Recovery Compression Socks

- 20-30 mmHg targeted compression

- Extra support on shin & calf area

- Post-workout & injury prevention

Nurse Compression Socks

- 15-20 / 20-30 mmHg graduated compression

- Breathable fabric for 12-hour shifts

- Professional look for clinical settings

Surgeon Compression Socks

- 20-30 mmHg firm support

- Extra calf support for 8+ hour surgeries

- Seamless toe for all-day comfort

Anti-Fatigue Compression Socks

- 15-20 mmHg with arch support

- Cushioned sole reduces foot fatigue

- Designed for standing all day

Fashion Compression Socks

- 15-20 mmHg comfortable compression

- Colorful designs nurses love

- Great for pediatric & friendly care settings

Everyday Compression Socks

- 8-15 / 15-20 mmHg gentle compression

- Lightweight & all-day comfortable

- Breathable fabric for daily wear

Sheer Compression Socks

- Reduces leg swelling from sitting

- Available in classic colors for men & women

- 15-20 mmHg subtle compression

Flight Compression Socks

- Lightweight & carry-on friendly

- Comfortable for 8-12 hour wear

- Reduces DVT risk on long-haul flights

Dress Compression Socks

- Reduces leg swelling from sitting

- Available in classic colors for men & women

- 15-20 mmHg subtle compression

Specialized Features Available

Functional Features

Zipper

Easy on and off with a convenient zipperclosure for those with limited mobility

Non-Slip Grip

Silicone treads on sole provide superiortraction and prevent slipping on smooth surfaces

Copper-Infused

Advanced copper fiber technologyprovides natural antimicrobial protectionand odor control

Styles & Features

Full Print & Dye

Tie-dye, sublimation, and 360° seamless printing available. Turn any design into a finished product.

Wide Calf

Extra wide design accommodates largercalves up to 25+ inches for comfortable all-day wear

Toeless

Open toe and heel design allows you towear your favorite shoes while getting compression benefits

What We Can Customize For You

From compression levels to packaging — every detail can be customized to fit your brand and sales channel.

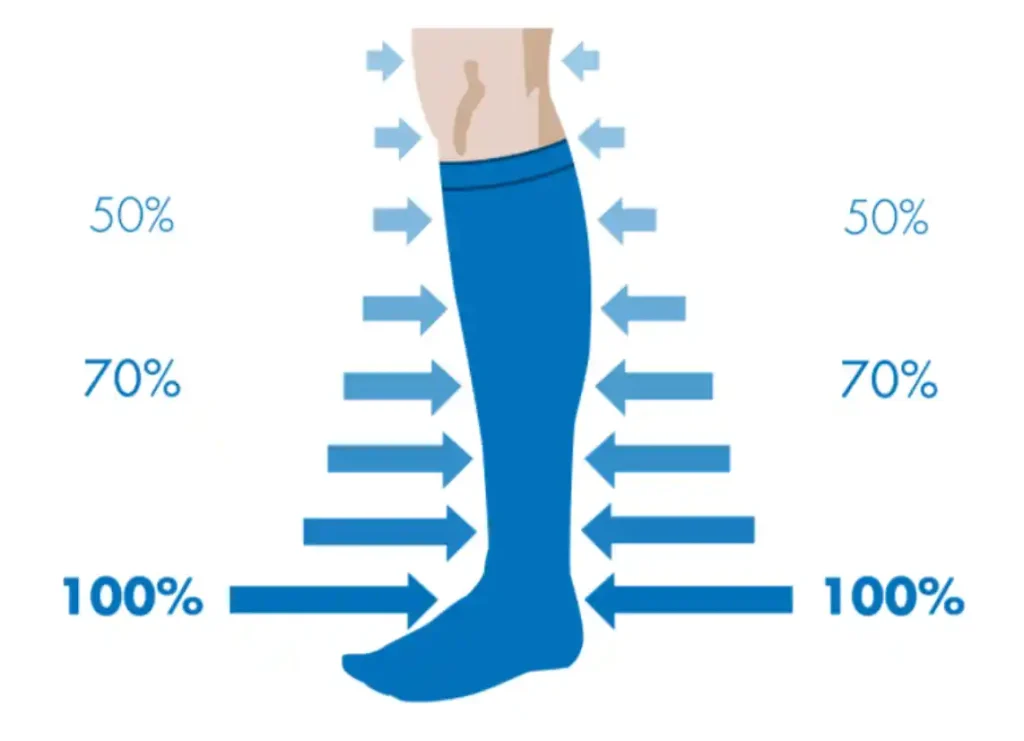

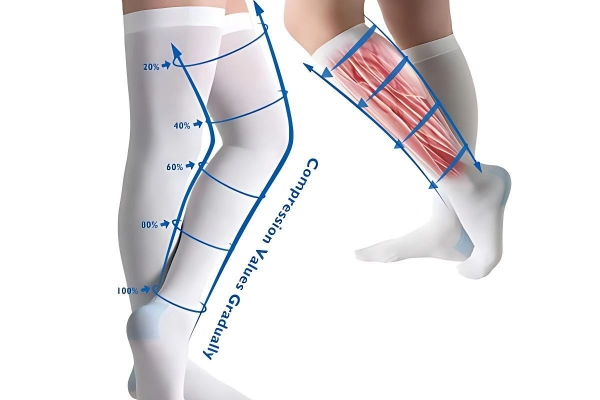

Compression levels

Gentle daily support for tired legs. Best for wellness-focused lifestyle brands and e-commerce sellers targeting everyday consumers.

Ideal for travel, desk jobs, and early pregnancy. Popular with travel brands, nurse/workwear lines, and maternity products.

Recommended for varicose veins, pregnancy, and post-surgery recovery. Suitable for pharmacy channels, medical suppliers, and healthcare brands.

Clinical-level support for DVT, severe edema, and prescription use. Designed for medical distributors and hospital supply chains. Requires proper sizing guidance.

💡 Not sure which level fits your market? [How to Choose the Right Compression Level →]

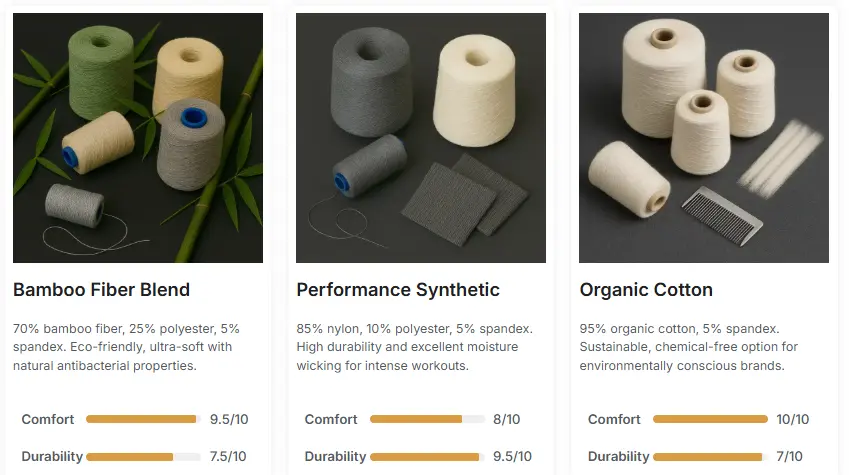

High elasticity, durability, and moisture-wicking performance. The go-to choice for sports brands and athletic compression lines.

Naturally soft, breathable, and antibacterial. Ideal for maternity brands and customers with sensitive skin.

Ultra-soft with excellent sweat absorption. Popular for medical recovery, daily wear, and lifestyle-focused brands.

Natural temperature regulation and odor resistance. Perfect for outdoor brands and cold-environment workwear.

Special Features

Explore multiple special features includes arch support bands, cushioned soles, seamless toe closure, anti-slip grips, reflective yarn for night visibility - meeting all special needs.

- Seamless Toe

- Reinforced Heel & Toe

- Y Heel

- 3D cushion Design

Packaging Options

Custom packaging such as header cards, labels, wrap bands, or individual boxes with your branding. We can also print your barcodes or provide custom poly bags.

- Display & Gift Box

- Branded Packaging Design

- Sustainable Packaging Options

- Amazon-friendly vacuum-sealed packaging

Your Challenges, Our Solutions

Whether you’re managing a retail brand, launching a new product line, or handling global procurement, sourcing custom compression socks can be full of unknowns. We understand the common roadblocks — and more importantly, how to solve them with speed, clarity, and hands-on support.

Quality

"I've been burned by inconsistent quality!"

Our Solution

3-step in-line QC during production + final inspection after packaging. Every checkpoint is signed off by a dedicated inspector — full traceability, zero finger-pointing.

[See Our QC Process →]

Speed

"I need it fast, but don't want to sacrifice quality"

Our Solution

Standard lead time: 25-30 days. Need it faster? Talk to us — we can allocate extra machines and adjust schedules for urgent orders.

Design Accuracy

""Will the sample match my design?"

Our Solution

Free design mockups within 24h and physical samples before production. We'll remake samples until perfect.

Client Success Stories

Our success is best measured by the success of our clients. We’re proud to have partnered with businesses of all sizes across the globe. Here are a few examples.

E-commerce Seller Differentiation

Amazon Top Seller

An Amazon e-commerce entrepreneur was selling compression socks as a top-rated product but faced stiff competition from low-cost rivals. They approached us to develop a new differentiated compression sock that could set their listing apart.

“The team’s dedication to perfecting our product was beyond expectation. After over ten sample revisions, our sales rebounded, and we’ve built a stronger brand—we couldn’t have done it without such a supportive manufacturing partner.”

Result: Successful product relaunch that not only maintained high review ratings but also commanded a higher price point due to premium features.

Maternity & Healthcare Brand

A company focusing on maternity wear

A mid-sized company focusing on maternity wear and postpartum recovery worked with us to produce a line of maternity compression socks. Their key concerns were safety, comfort, and regulatory compliance for the sensitive needs of pregnant women.

“Having a manufacturing partner who truly understands our product and cares about our customers’ wellbeing has been invaluable. Their documentation and clinical testing support were priceless.”

Result: Successfully launched products in retail stores and online, with consistent quality and timely deliveries enabling confident expansion into multiple markets.

Industrial Safety Integration

PPE Distributor

An established PPE (Personal Protective Equipment) distributor wanted to add compression work socks to their portfolio for workers who stand all day. Their priorities were durability, compliance with safety standards, and integration with their existing product range.

“Zhongzhi Industry demonstrated exceptional knowledge in technical materials and delivered exactly as promised. They are now a key supplier in our chain.”

Result: The first order was delivered on time and passed their internal quality tests. They’ve since become a repeat customer, expanding their made-in-China product range with our help.

Compression Sock Assurance Center

We go beyond standard production. Our compression socks are developed and tested with specialized medical-grade equipment — including pressure testing machines, stretch resistance testers, and dedicated medical knitting machines. Certified to meet international standards for quality, safety, and performance.

Advanced Testing Machines

We ensure every pair meets strict pressure and durability standards.

Medical Merz & Lonati Machines

Compression Level Testing Machine

Socks Stretching Testing Machine

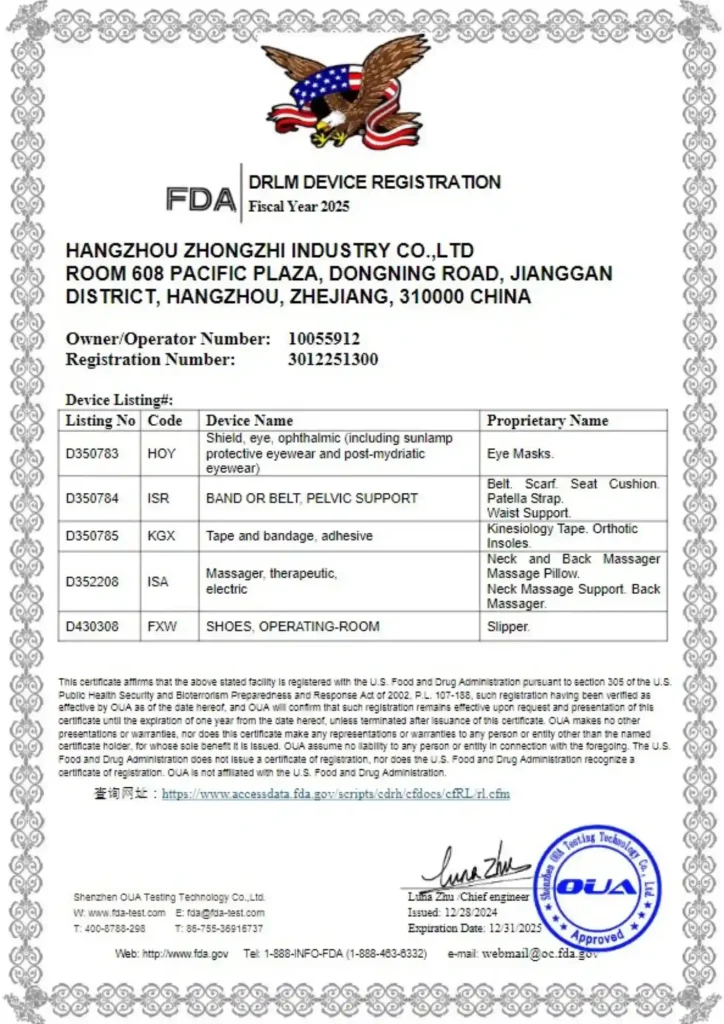

FDA

ISO13485

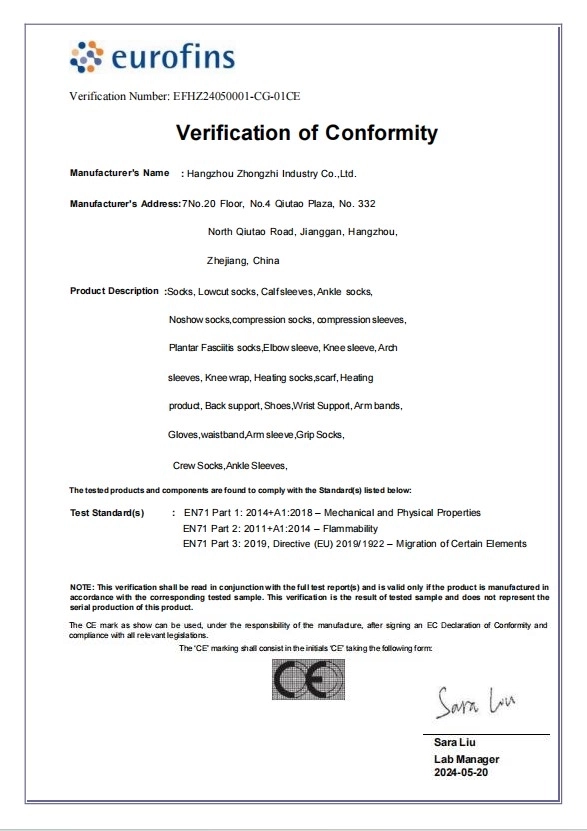

CE

Certified Compression Quality

We’re certified to ISO 13485 and OEKO‑TEX® Standard 100, and CE to ensure medical‑grade safety and performance. Download our full certificates & third‑party test reports to verify instantly and share with your QA team.

Custom Wholesale Compression Socks: Business Client FAQ

What customization options are available for compression socks?

We can custom socks colors, design, sizes, logo, material and packaging. For sizes, we also provide plus size like XXL, XXXL…etc to wider-calf groups.

What compression levels are available for your custom socks?

We offer 8-15mmHg, 15-20mmHg, 20-30mmHg, 30-40mmHg. And can custom compression levels according to your request. Free level testing service provided!

Can I specify custom materials and blends for my compression socks?

Yes. We can produce with different materials (cotton, nylon, spandex, bamboo, polyester, coolmax, etc.) with several unique materials.

How do you ensure consistent quality for bulk orders?

We have strict quality control procedures throughout production, from yarn sourcing to final inspections, ensuring every pair meets your standards.

What is the typical lead time for custom compression socks?

Our regular sample time is 5-7 days, and 20-25 days for bulk production. We also offer different options for shipping, 7-10 days by express, 25-30 days by sea or air DDP worldwide.

What is the process for sample and order?

Confirm specifications like material, size and designs for socks, then we will start sample production after sample cost paid. After sample confirmed, we will start bulk production after initial payment is done.

Ready to Start Your Compression Sock Project?

At Hangzhou Zhongzhi, we combine professional quality with a personalized approach. Let’s create something great together!

Inquiry & Consultation

Share your project details, and our experts will reply within 24 hours with price and solutions.

Sample Development

We craft samples to your specs and send approval photos within 3-7 days.

Sample & Order Confirmation

Confirmation Review your samples and request any refinements. Upon approval, we finalize your order details with a deposit to begin production.

Bulk Production

Production time varies by quantity; regular production time is 3-4 weeks.

Quality Inspection & Shipping

We will ship the bulk order after QC inspection. Choose between express air shipping (5-7 days) or sea freight (3-5 weeks) for most areas.

Insights That Help You Source Smarter

Explore expert tips, industry trends, and practical guides on custom sock manufacturing, materials, certifications, and sourcing strategies. Whether you’re launching a new line or optimizing supply chains, our articles support informed decisions and better results.

Explore our in-depth guide to custom sock solutions—covering materials, advanced logo techniques, and eco-smart packaging—designed to help brands carve a unique identity, reduce costs, and accelerate speed-to-market. See real industry examples and discover how we turn concepts into globally successful product lines.

Explore the six critical elements that affect the cost of compression socks, including material selection, compression levels, manufacturing complexity, and certifications. This guide provides valuable insights for brands and retailers aiming to make informed sourcing decisions.

Choosing the appropriate compression level is crucial for meeting your customers’ needs. This guide provides five practical tips to help brands and retailers select the right compression levels, ensuring product effectiveness and customer satisfaction.

Learn why maternity compression socks are the fastest-growing compression niche and how brands can spec, customize, and manufacture medical-grade styles that truly support pregnant women—while boosting margins across online and maternity channels.

Understand 15–20 vs 20–30 mmHg compression socks so you can recommend the right level for your customers, improving comfort, compliance, outcomes, and inventory decisions for clinics, retailers, and distributors.

Understand why some customers’ legs ache after compression sock use—covering fit, pressure level, wear time, and contraindications—so you can select products, educate users, reduce post-wear complaints, and optimize compliance rates.